Test method for simulating flowing state of oil well cement paste and integrating maintenance and test

A technology of oil well cement slurry and flow state, applied in the field of oil drilling, can solve the problems of not being able to simulate the temperature and pressure environment of the process well, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

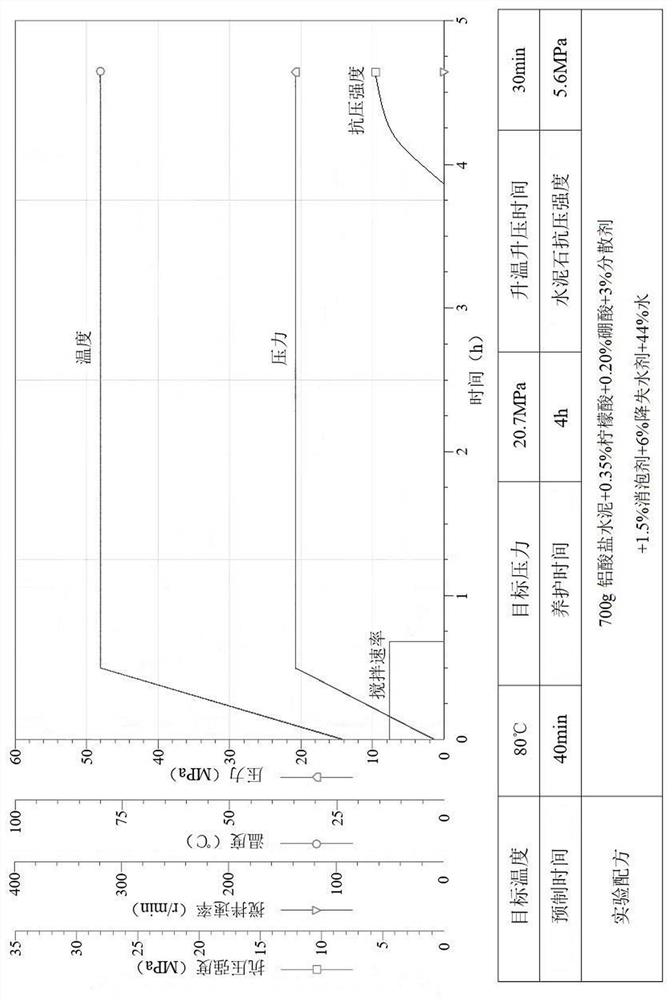

Embodiment 1

[0042] Such as figure 1 As shown, this embodiment discloses a test device for simulating the flow state of oil well cement slurry and integrating maintenance and testing, including a sealable slurry cup for holding the cement slurry 7 and a sealed kettle for placing the sealable slurry cup A stirring mechanism is arranged in the sealable pulp cup, and the upper end of the stirring mechanism passes through the sealable pulp cup and the sealed kettle body; it also includes a transmission mechanism controller 10 for controlling the rotation of the stirring mechanism in the sealable pulp cup, The temperature control subsystem 16 used to detect and control the temperature in the sealable slurry cup and the sealed kettle body, the pressure control subsystem 19 used to detect and control the pressure in the sealed kettle body, and the ultrasonic wave used to detect the ultrasonic propagation speed in the slurry cup The control subsystem 24 is connected with the transmission mechanism...

Embodiment 2

[0051] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses:

[0052] A test device for simulating the flow state of oil well cement slurry and integrating maintenance and testing, including a sealable slurry cup for containing cement slurry 7 and a sealed kettle body for placing the sealable slurry cup, the sealable slurry cup A stirring mechanism is arranged inside, and the upper end of the stirring mechanism passes through the sealable pulp cup and the sealed kettle body; it also includes a transmission mechanism controller 10 for controlling the rotation of the stirring mechanism in the sealable pulp cup, which is used to detect and control the sealable pulp The temperature control subsystem 16 of the temperature in the cup and the sealed kettle body, the pressure control subsystem 19 used to detect and control the pressure in the sealed kettle body, the ultrasonic control subsystem 24 used to detect the...

Embodiment 3

[0071] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this embodiment discloses a test device and method for simulating the flow state of oil well cement slurry and integrating maintenance and testing. Bottom cover of slurry cup 5, slurry cup wall 6, cement slurry 7, paddle blade 8, rotary joint 9, transmission mechanism controller 10, heater 11, heater external joint 12, internal coupling temperature probe 13, internal coupling temperature Sensor 14, externally coupled temperature sensor 15, temperature control subsystem 16, pressurization and pressure relief interface 17, pressure sensor 18, pressure control subsystem 19, ultrasonic transmitter 20, transmitter connector 21, ultrasonic receiver 22, receiver Joint 23, ultrasonic control subsystem 24, confining pressure valve 25, hydraulic oil 26, and computer control system 27.

[0072] The kettle body top cover 1 is fixed on the upper end surface of the kettle body through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com