Air cylinder cover turnover device

A technology of turning over device and cylinder head, applied in the directions of transportation and packaging, conveyors, rollers, etc., can solve the problems of complex structure, high labor intensity, high physical strength consumption, etc., and achieves simple overall structure, high labor intensity, and reduced impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

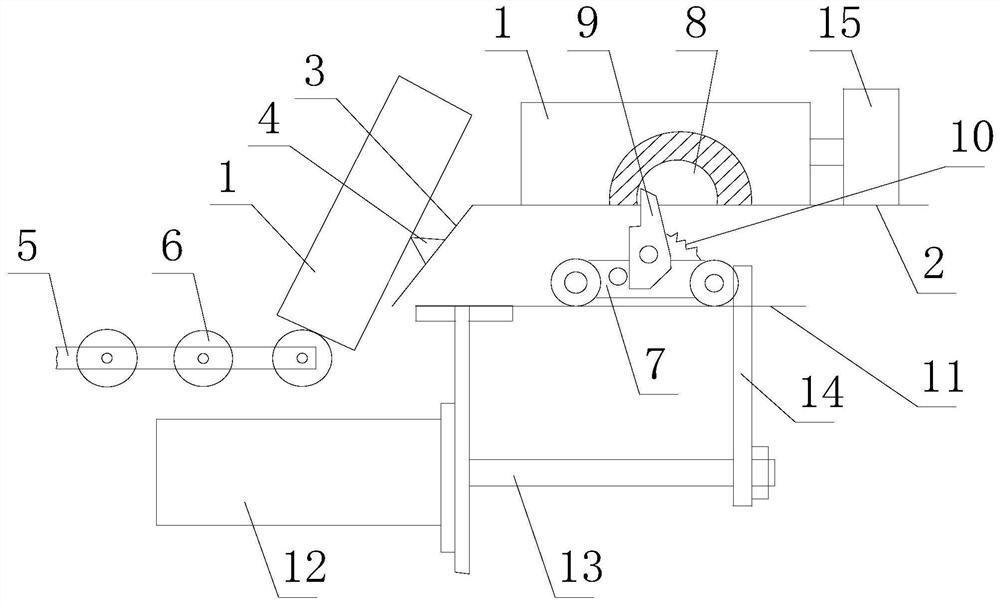

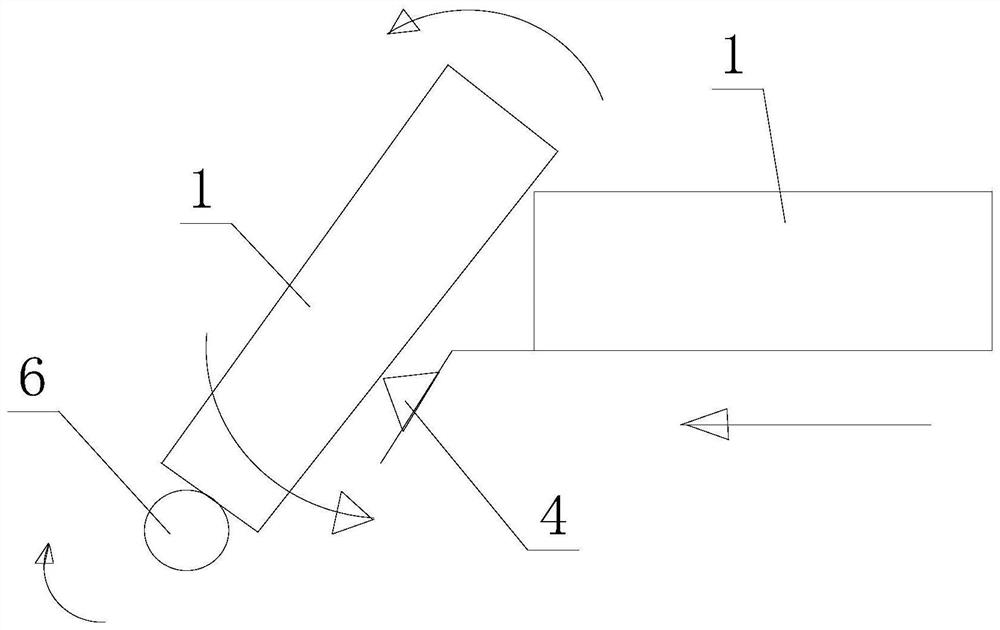

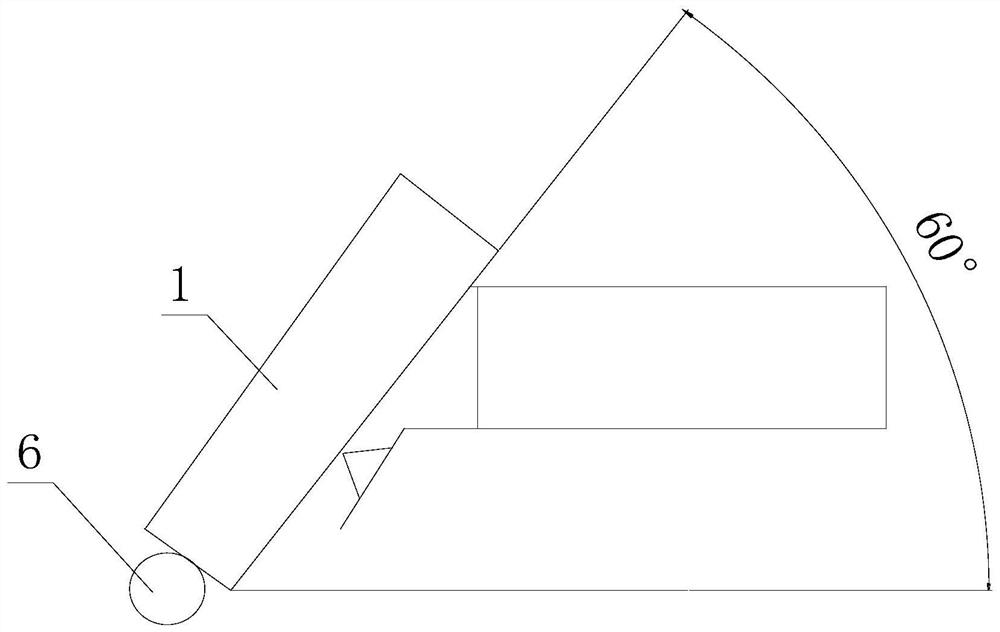

[0027] refer to Figure 1-5 , a cylinder head overturning device, comprising a conveying platform 2 for conveying a cylinder head 1 . One end of the conveying platform 2 is provided with an inclined surface 3, and the middle part of the inclined surface 3 is provided with a support boss 4, which can effectively increase the inclination angle of the cylinder head 1 when it is turned over for the first time. A roller table 5 is arranged below the inclined surface 3, and a roller 6 is arranged on the roller table 5. After the cylinder head 1 is overturned for the first time, the lower end of the cylinder head 1 is tangent to the outer circle of the roller 6. The conveying trolley 7 and the first drive mechanism for driving the conveying trolley 7 to reciprocate are arranged below the conveying platform 2 , and the conveying trolley 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com