Automobile front cabin cover hinge reinforcing plate

A hinge reinforcement plate and front cabin technology, which is applied to vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of large occupied area of flat structure, low structural strength, low yield rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

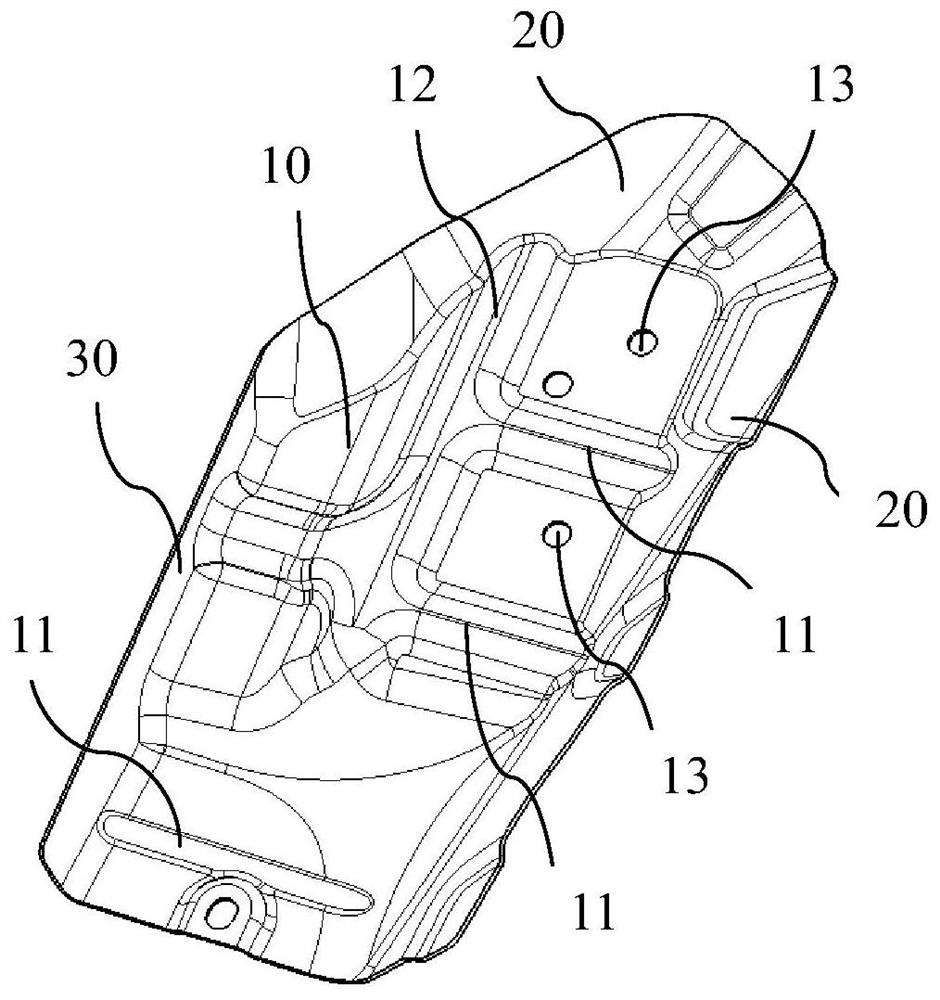

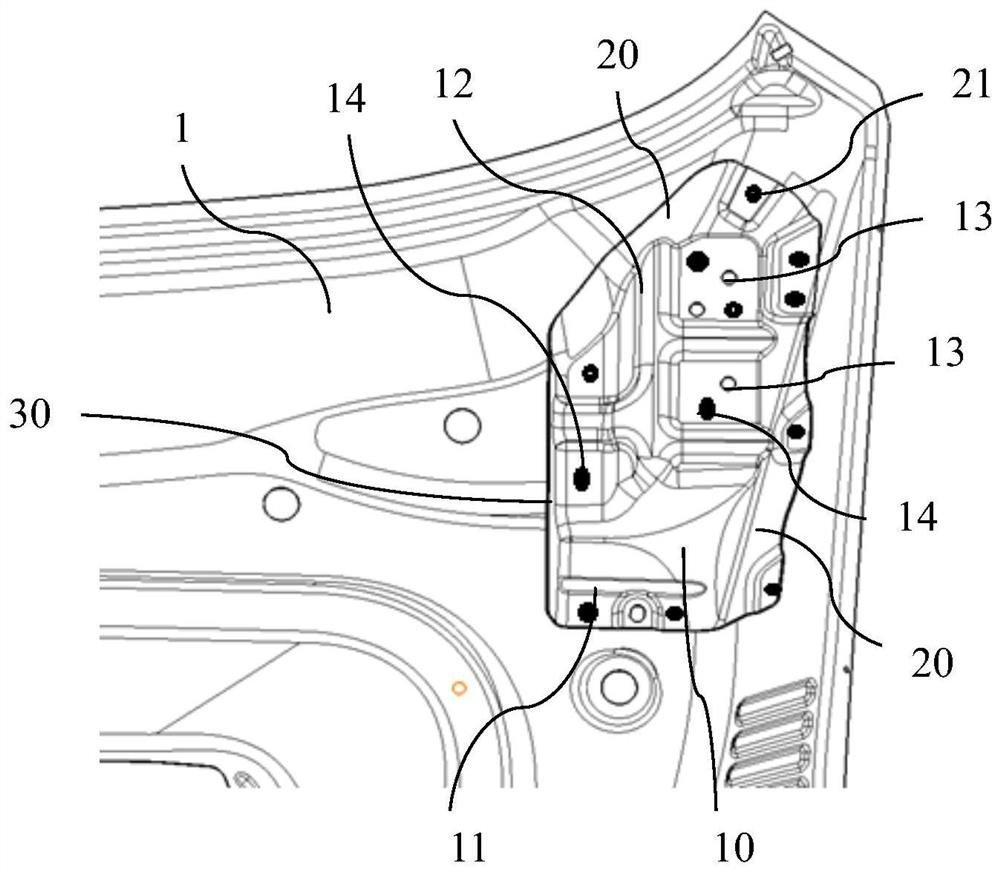

[0009] A kind of car front hatch hinge reinforcement plate, comprises the body 10 that is welded with the front hatch inner panel 1, and the side edge and rear side edge of described body 10 far away from the centerline of vehicle body are provided with obliquely folded plate 20, and obliquely folded plate 20 and Front hatch inner panel 1 is welded on the panel surface.

[0010] Because the shape requires the rear and side parts of the front hatch inner panel 1 to form a bent plate structure downwards, this forms the installation space for the hinge reinforcement plate in this application, and the hinge reinforcement plate itself forms a three-dimensional structure to improve its structural strength without additional The stamping flange is provided with a simple structure and saves installation area, and does not need to be installed at a relatively flat position on the inner panel 1 of the front hatch cover.

[0011] The side of the body 10 close to the centerline of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com