Graded die

A stamping die and hierarchical technology, which is applied in the field of stamping dies, can solve problems affecting the service life of stamping plates, achieve the effects of reducing manufacturing costs, simple device structure, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

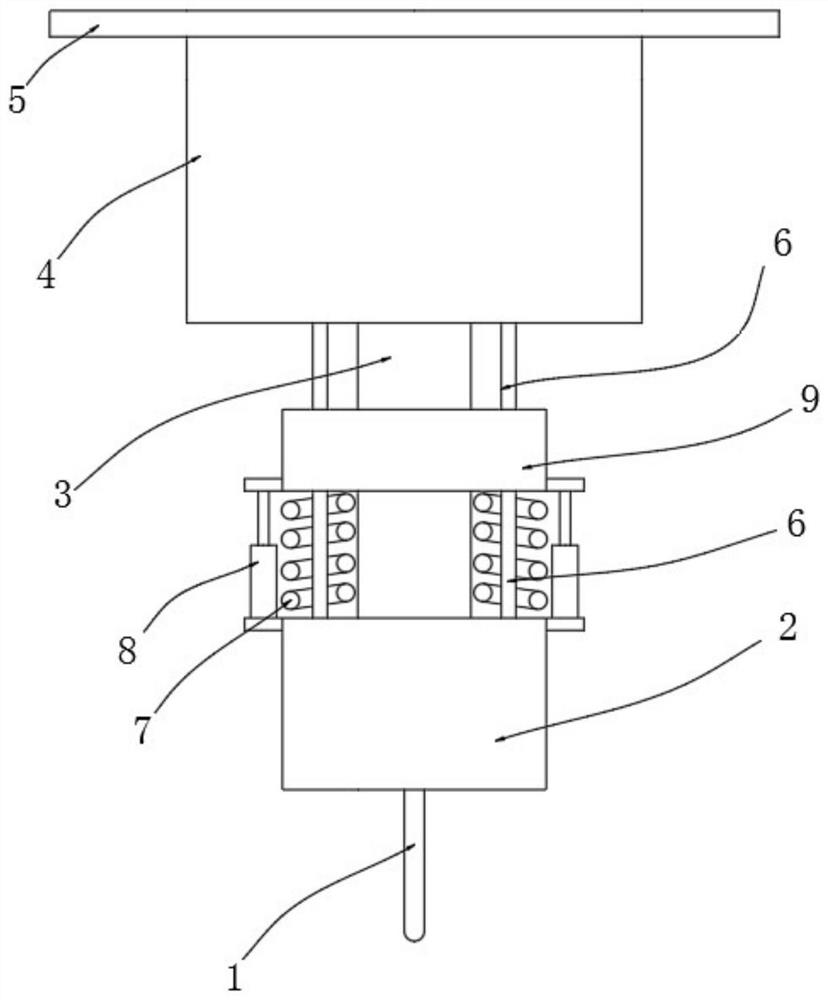

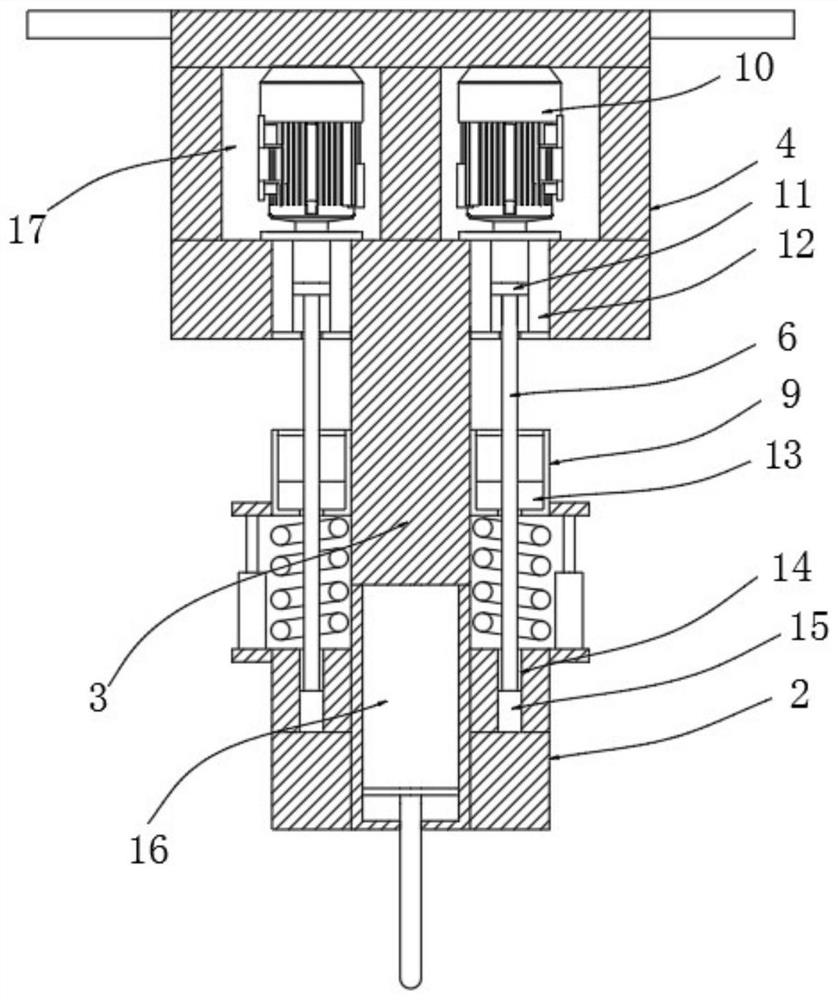

[0020] Such as figure 1 , figure 2 As shown, a staged stamping die includes a primary stamping part 3 and a secondary stamping part 2, the primary stamping part 3 is located inside the secondary stamping part 2, and the lower end of the primary stamping part 3 shows A positioning rod 1 is provided, and the positioning rod 1 slides freely along the vertical direction of the first-stage stamping part 3. The upper end of the first-stage stamping part 3 is fixedly connected with an upper plate 4, and the upper end of the upper plate 4 The position near the upper end of the outer surface is fixedly connected with a connecting plate 5, and the connecting plate 5 is fixedly connected with a stamping mechanism, and the stamping mechanism drives the first-level stamping part 3 and the second-level stamping part 2 to move down, and the second-level stamping part The lower end surface of 2 is tightly pressed on the surface of the workpiece to be stamped, and the first-level stamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com