Online roller surface cleaning device

A cleaning device and technology to be cleaned, applied in cleaning methods and utensils, cleaning methods using tools, keeping roller equipment in an effective state, etc., can solve problems such as roller damage, scratches, increase labor intensity, etc., and achieve stable working process. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

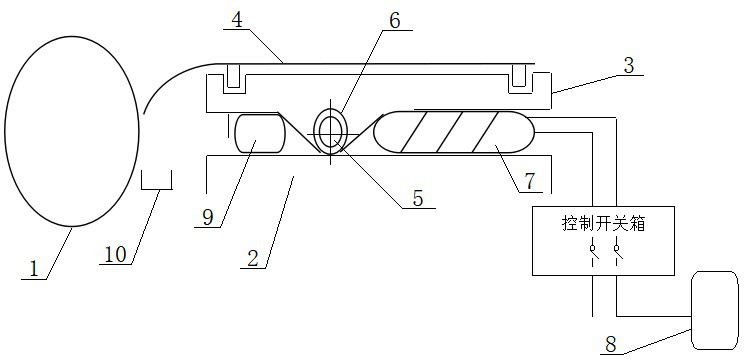

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0016] The present invention designs an online roller surface cleaning device, which is used to clean the surface of the roller 1 to be cleaned. In practical applications, it specifically includes a base 2, a movable plate 3, a scraper 4, a rotating shaft 5, a rotary spring 6, and an air bag 7. , Compressed air source 8, control switch box, block 9, collection tank 10.

[0017] Wherein, the lower surface of the movable plate 3 is movably connected to the upper surface of the base 2 through the rotating shaft 5, and the movable plate 3 rotates with the rotating shaft 5 as the axis; The edge is a straight line, and the length of the blade edge is not less than the length of the roller 1 to be cleaned; the front end of the scraper 4 is not coplanar with the blade body, and forms an obtuse angle with each other; the scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com