Atomizing cup with adjustable collision distance

An atomization cup and distance technology, which is applied in the field of medical nebulizers, can solve problems such as the inability to achieve accurate adjustment of fogging volume and droplet diameter, the inability to ensure the same lifting and lowering of the collision surface, and the inability to accurately control the rotation adjustment angle. Achieve the effects of good fogging effect, small adjustment error, and avoid adjustment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

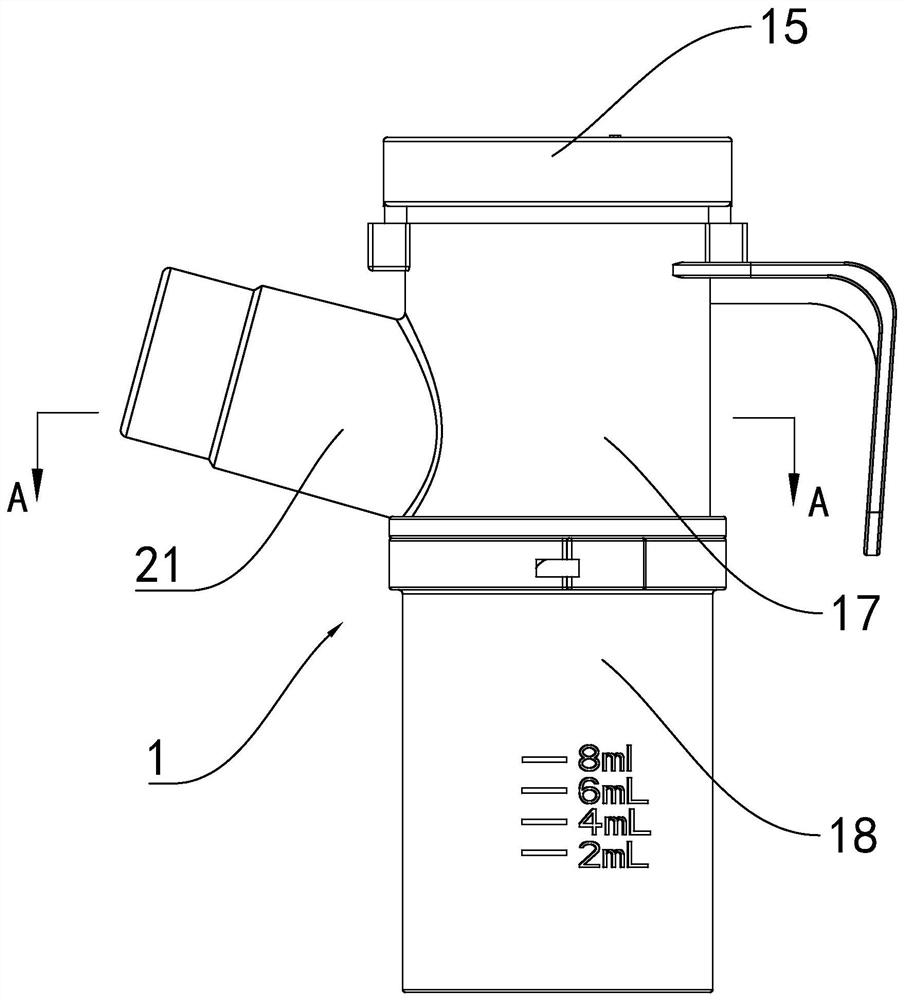

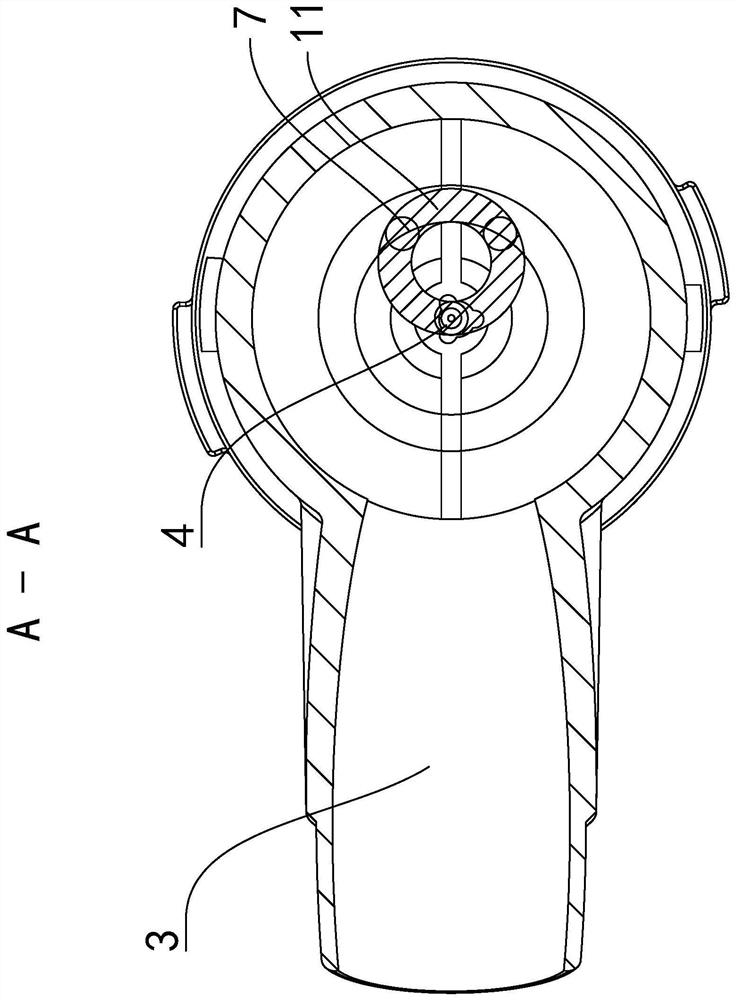

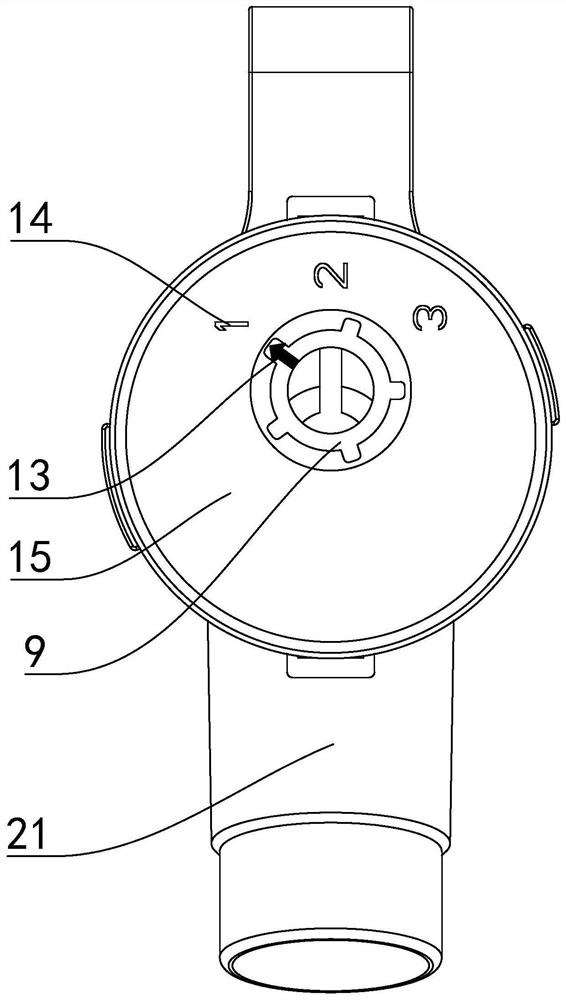

[0069] Embodiment one: see attached figure 1 to attach Figure 5 As shown, an atomization cup with adjustable collision distance includes a cup shell 1, a cup cover 15, a cup core 16, a mist outlet 21 and a venturi tube 20;

[0070] There is a cavity 2 in the cup shell 1, and the part containing the liquid medicine in the cavity 2 is defined as the lower part;

[0071] The cup shell 1 is composed of an upper cup 17 and a lower cup 18, the lower end of the upper cup 17 is embedded in the upper opening of the lower cup 18; the venturi tube 20 is positioned at the bottom end of the lower cup 18, and the venturi tube 20 The jet port 4 is located in the cavity 2; the cup core 16 is covered on the upper end of the Venturi tube 20 in a clearance fit manner, the gap between the two is a drainage gap 22, and the cup core 16 is provided with a hole for the jet to pass through. In the assembled state, the hole is aligned up and down with the jet port 4, and the lower end of the upper c...

Embodiment 2

[0082]Embodiment two: see attached Figure 6 , the difference between embodiment two and embodiment one is:

[0083] The adjustment part 5 is a slider 12, and the slider 12 is slidably arranged in the interlayer 19 on the upper end of the cup shell 1 vertically. The lower end surface of the block 12 is fixedly connected to the upper end of each of the collision bodies 6;

[0084] Each of the colliding bodies 6 is extended along the vertical direction, and is fixedly connected to the slider 12 in a parallel arrangement, and the arrangement direction is the same as the sliding direction of the slider 12;

[0085] In the sliding state, the motion trajectory of each collision surface 7 forms a straight strip, and viewed from the up and down direction, the jet port 4 is located on the motion trajectory of each collision surface 7, so that the jet port 4 can face each collision surface with different collision distances 7;

[0086] Preferably, the collision assembly further inclu...

Embodiment 3

[0088] Embodiment three: see attached Figure 7 , the difference between embodiment three and embodiment one is:

[0089] The adjustment part 5 is rotationally connected with the cup shell 1, and the rotation axis 10 of the turntable 8 forms an obtuse angle with the jet direction 3 of the jet port 4;

[0090] Each of the collision bodies 6 is a bent cylinder, and the arrangement of the collision surface 7 of each collision body 6 around the rotating shaft 10 is fixedly connected with the adjustment part 5, and the axial distance of each collision surface 7 from the rotating shaft 10 is equal;

[0091] In the rotating state, the trajectory of each collision surface 7 forms a circular ring, and its circular trajectory is not perpendicular to the jet flow direction 3, and viewed along the jet flow direction 3, the jet port 4 is located on the trajectory of each collision surface 7, and each collision surface 7 The collision distances with the jet ports 4 are not equal, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com