Pull-back-type safe self-destruction injection device

An injection device and a pull-back technology, which are applied in the field of pull-back safety self-destruction injection devices, can solve the problems of inability to fully realize zero-position injection, inability to inject gas or liquid, and threats to the personal safety of the injector, and achieve automatic destruction. , the effect of easy operation, improving the safety and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

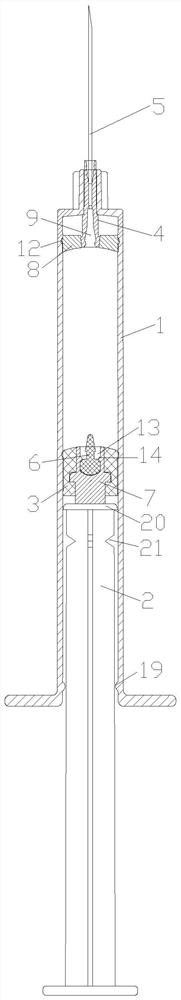

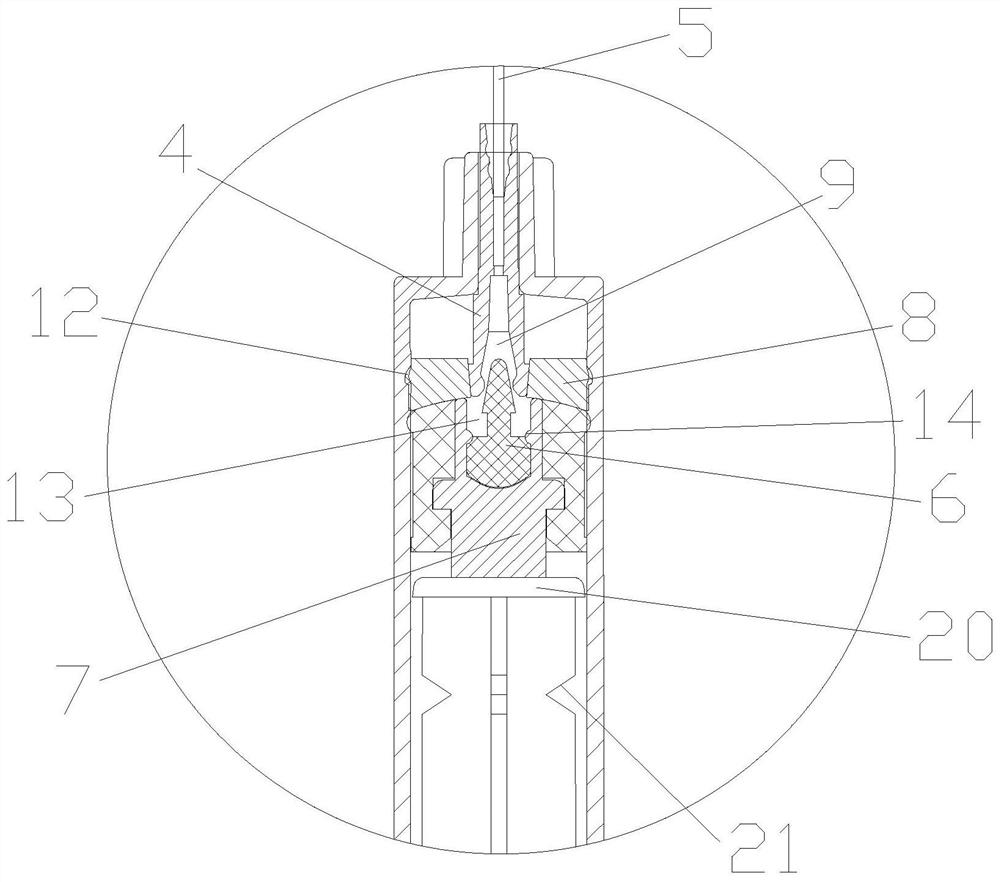

[0027] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] In this application, the shape of the bottom end surface of the self-destruct rubber plug 8 is the same as that of the top end surface of the piston 3, so as to ensure zero-position injection when it is pushed to contact. In the through hole 10, the buckle fixing seat 10 is fixed by setting an annular protrusion in the middle and embedded in the groove in the through hole 10, so that the core rod 2 can push the piston 3 to move up and down during the moving process.

[0029] See Figure 1-9 Shown is a pull-back safety self-destruct injection device, including an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com