Pressure cooker

A pressure cooker and pressure limiting technology, applied in the field of pressure cooker, can solve the problem of forced opening and other problems, and achieve the effect of increasing safety protection and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

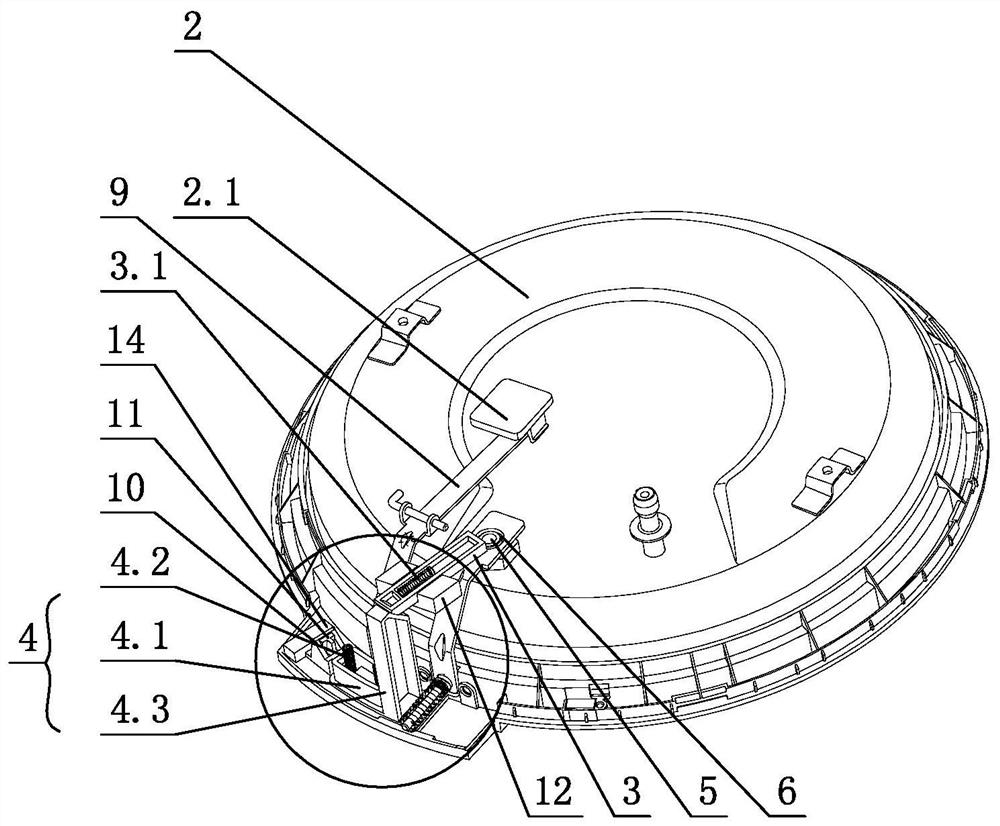

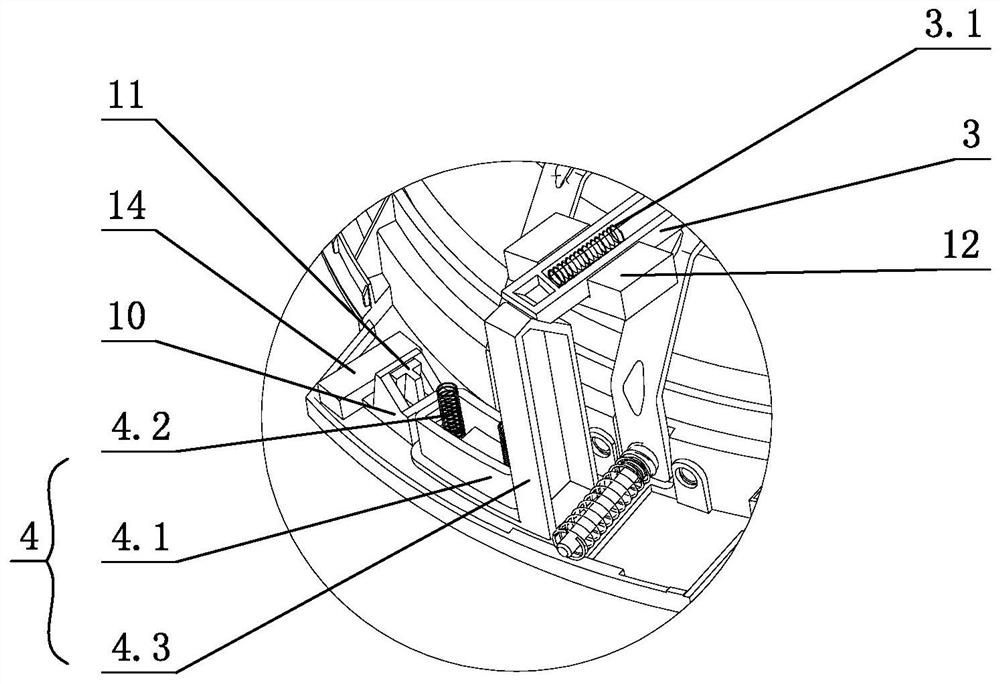

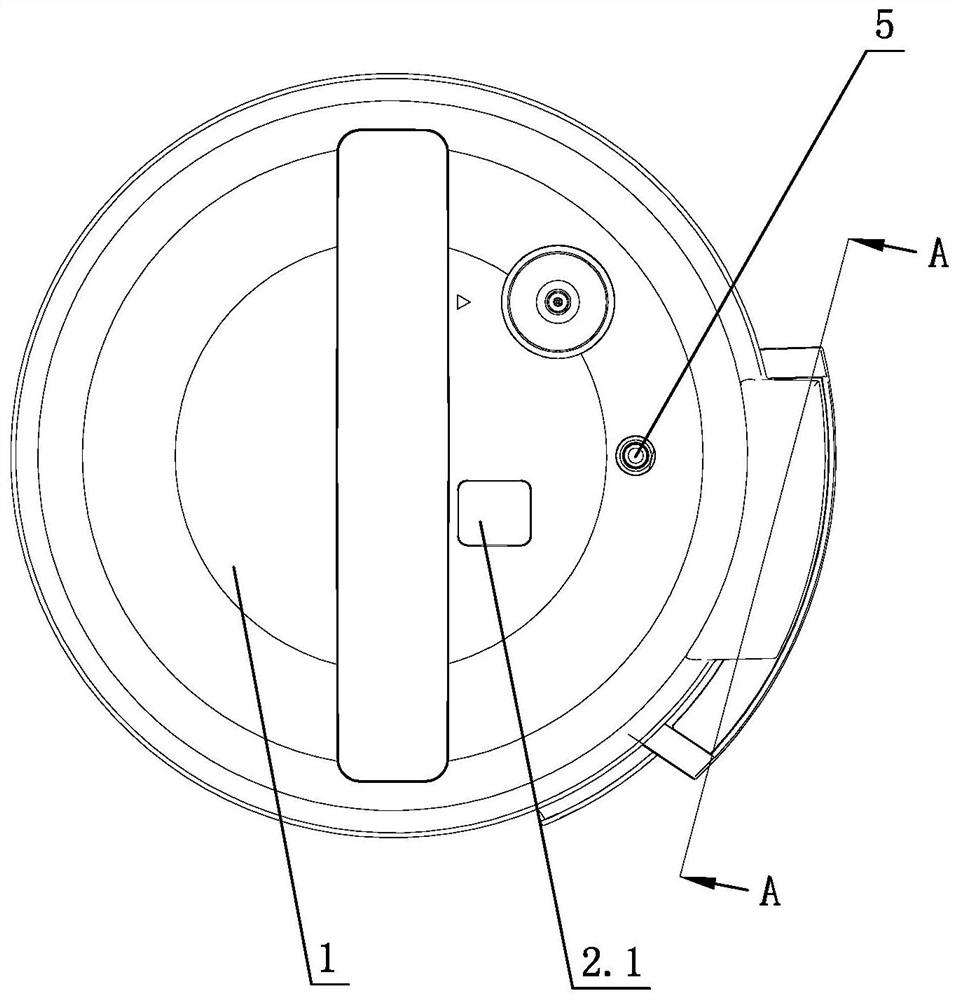

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] see figure 1 , a pressure cooker, comprising a cover 1 and an upper cover 2 assembled into a pot cover, the assembly gap between the cover 1 and the upper cover 2 forms an installation space, the upper cover 2 is provided with an exhaust port 6, and the exhaust port 6 A float valve 5 is provided, and a float valve pressure limiting rod 3 that moves forward and backward is provided in the installation space, and a guide stopper 4 that triggers the movement of the float valve pressure limiter rod 3, the guide stopper 4 moves up and down and is set in the installation space, and the float valve One end of the pressure limiting rod 3 is located on one side of the exhaust port 6, and the face cover 1 or the upper cover 2 is provided with a button 2.1, and the button 2.1 is connected with the guide block 4 in cooperation.

[0040] A guide block 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com