Evaluation method for reliability of measured value of dpf differential pressure sensor and diesel engine

A technology of DPF and diesel engine, which is applied in the measurement of pressure difference between multiple valves, testing of machine/structural components, measuring devices, etc. It can solve the problems of affecting DPF regeneration, excessive deviation of true value, and inaccurate estimation, etc. Achieve the effect of improving judgment accuracy and reducing the probability of inaccurate estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

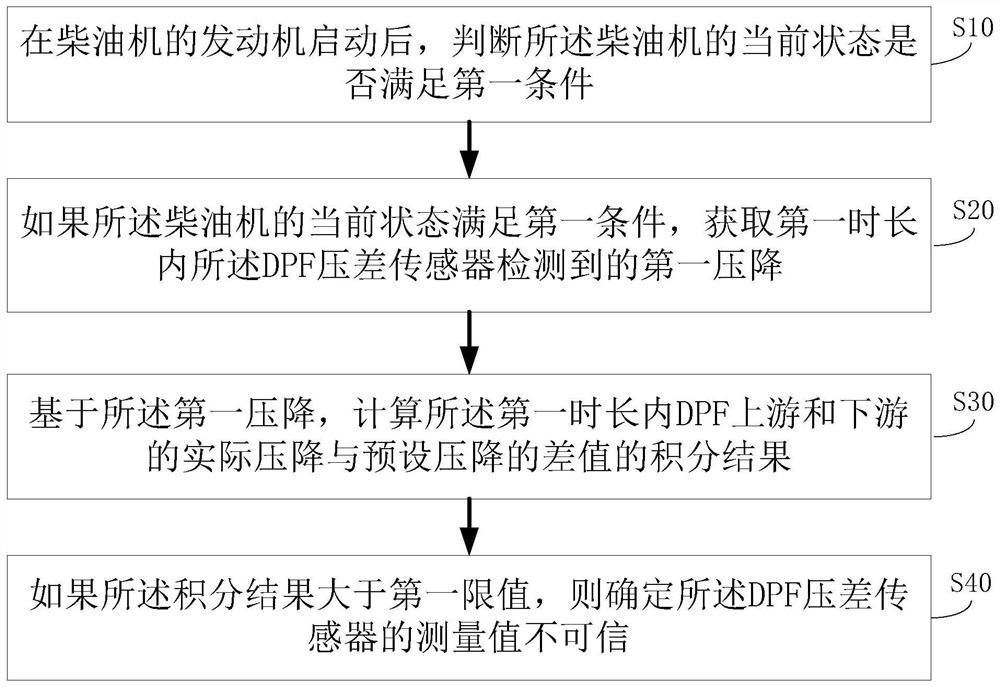

[0049] The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, but not all of the embodiments. Based on the embodiments in this application, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of this application.

[0050] Many specific details are set forth in the following description to facilitate a full understanding of the present application, but the present application can also be implemented in other ways different from those described herein, and those skilled in the art can do so without departing from the connotation of the present application. Similar promotion, therefore, the present application is not limited by the specific embodiments disclosed bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com