Bilberry water-light composition and preparation method thereof

A composition and a technology of orange water, applied in the field of skin care products, can solve the problems of inability to maintain makeup effect, skin care products cannot achieve skin care moisturizing effect, loss of moisture, etc., achieve long-term moisturizing and nourishing effect, and improve long-term water-locking and moisturizing ability. , The effect of delaying skin aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

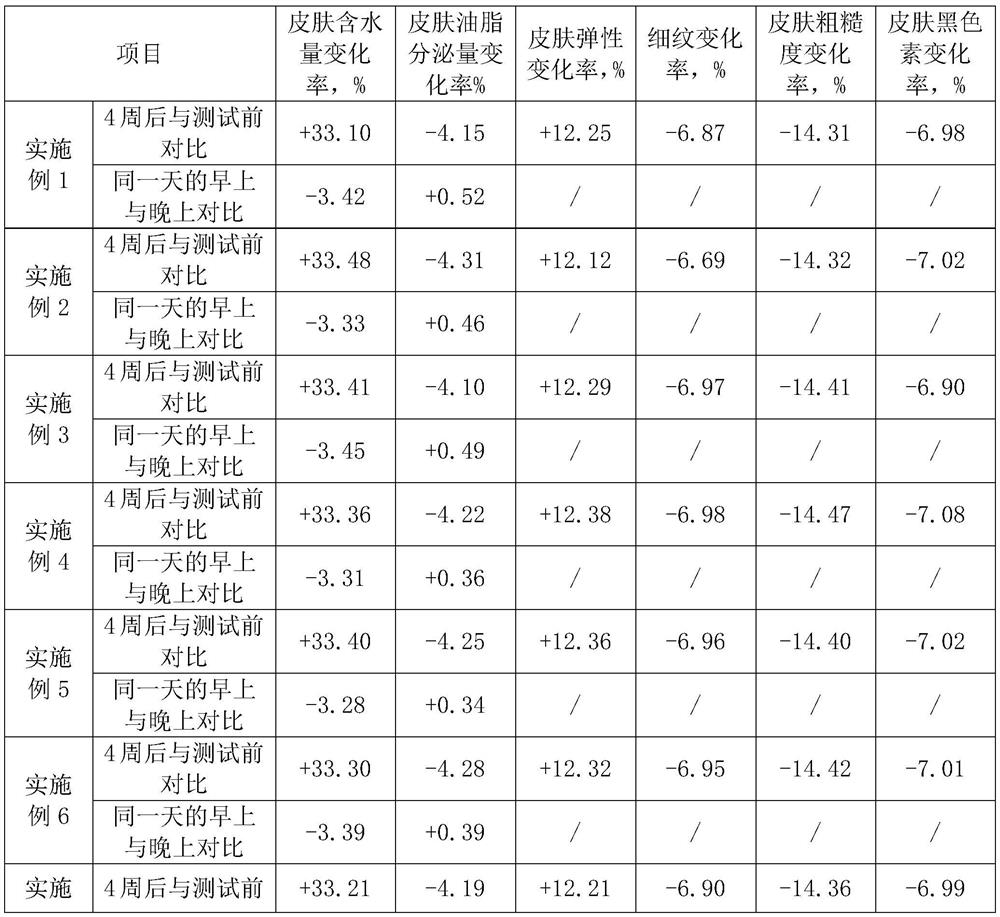

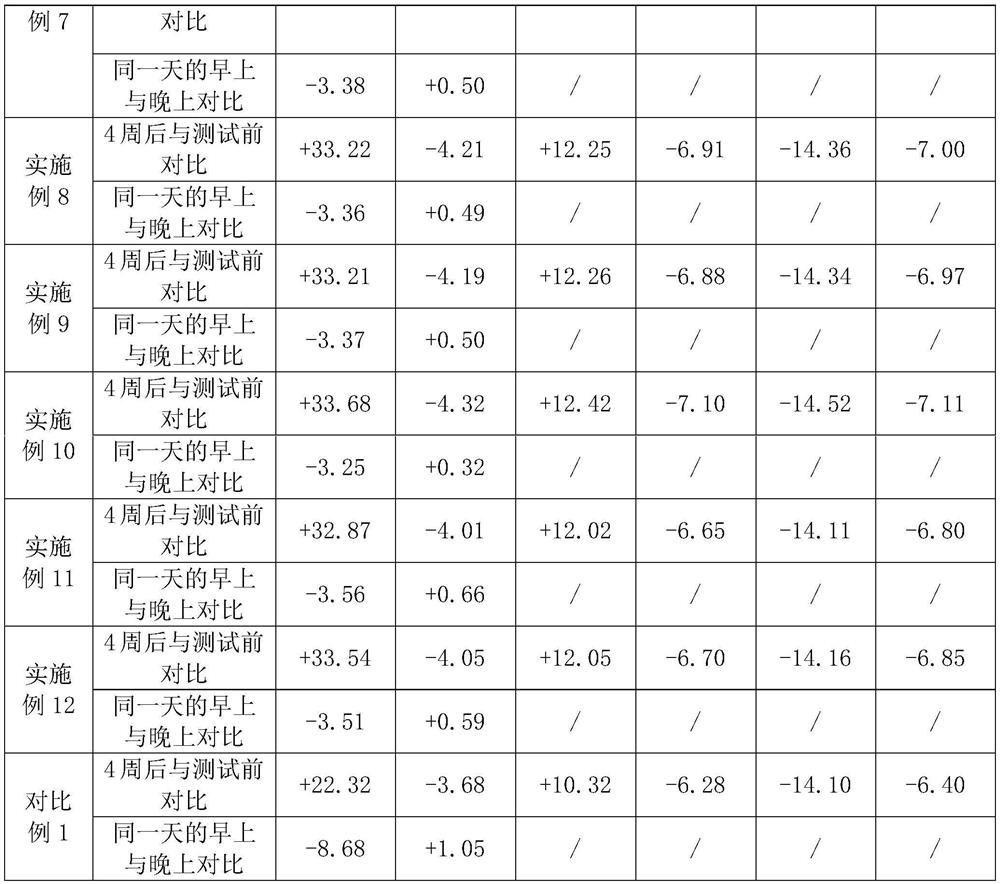

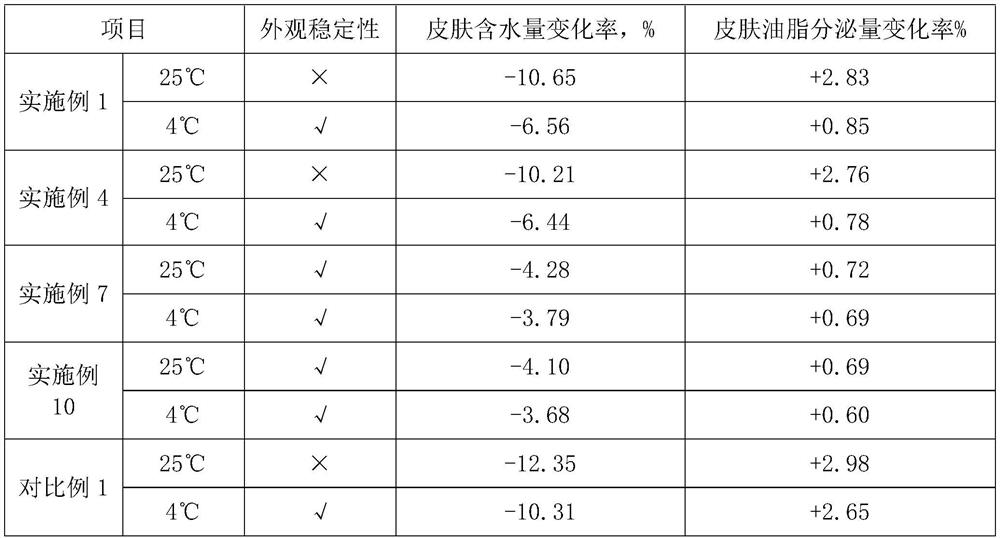

Examples

preparation example 1

[0040] Preparation example 1 of refined vegetable seed oil: according to the weight ratio of 3:2:1:1:1, American hazelnut oil, sea sandalwood seed oil, borage seed oil, carrot seed oil and coffee apricot seed oil are taken, Stirring at a speed of 1000r / min for 30min at a temperature of 40°C to obtain premixed seed oil;

[0041] Add 10 times the weight of absolute ethanol to the premixed seed oil, shake at a temperature of 10°C for 10 minutes at a frequency of 100-150 times / min, then centrifuge at a speed of 6000r / min for 20 minutes, and let stand for 2 hours. After the layers are separated, the precipitate is discarded to obtain the pretreated seed oil;

[0042] Homogenize the pretreated seed oil under high pressure for 30 minutes at a temperature of 20°C and a pressure of 1000 bar to obtain a premix; centrifuge the premix at a speed of 6000 r / min for 30 minutes, then distill under reduced pressure to remove ethanol to obtain fine Chemicalized vegetable seed oil.

preparation example 2

[0043] Preparation example 2 of refined vegetable seed oil: according to the weight ratio of 3:2:1:1:1, American hazelnut oil, sea sandalwood seed oil, borage seed oil, carrot seed oil and coffee apricot seed oil are taken, Stirring at a speed of 1250r / min for 25min at a temperature of 45°C to obtain premixed seed oil;

[0044] Add 12 times the weight of absolute ethanol to the premixed seed oil, shake at a frequency of 120 times / min at a temperature of 15°C for 8 minutes, then centrifuge at a speed of 7000r / min for 15 minutes, and let it stand for 2.5 hours. After the layers are separated, the precipitate is discarded to obtain the pretreated seed oil;

[0045] Homogenize the pretreated seed oil under high pressure for 25 minutes at a temperature of 25°C and a pressure of 1100 bar to obtain a premix; centrifuge the premix at a speed of 7000 r / min for 25 minutes, then distill under reduced pressure to remove ethanol to obtain fine Chemicalized vegetable seed oil.

preparation example 3

[0046] Preparation example 3 of refined vegetable seed oil: according to the weight ratio of 3:2:1:1:1, American hazelnut oil, sea sandalwood seed oil, borage seed oil, carrot seed oil and coffee apricot seed oil were taken, Stirring at a speed of 1500r / min for 20min at a temperature of 50°C to obtain premixed seed oil;

[0047] Add 15 times the weight of absolute ethanol to the premixed seed oil, shake at a frequency of 150 times / min at a temperature of 20°C for 5 minutes, then centrifuge at a speed of 8000r / min for 10 minutes, let it stand for 3 hours, and wait for it to After stratification, discard the precipitate to obtain the pretreated seed oil;

[0048] Homogenize the pretreated seed oil under high pressure for 20 minutes at a temperature of 30°C and a pressure of 1200 bar to obtain a premix; centrifuge the premix at a speed of 8000 r / min for 20 minutes, then distill under reduced pressure to remove ethanol to obtain fine Chemicalized vegetable seed oil.

[0049] Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com