A non-destructive separation method of interlayer interface of asphalt pavement structure based on indoor forming

A technology of asphalt pavement and separation method, which is applied in the direction of analyzing materials, preparation of test samples, sampling, etc., can solve the problems of difficult to accurately define the interface boundary between asphalt pavement structure layers, expensive CT scanning equipment, complicated technical operation, etc., to achieve Rich in mesoscopic information, easy to promote and use, and obvious separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

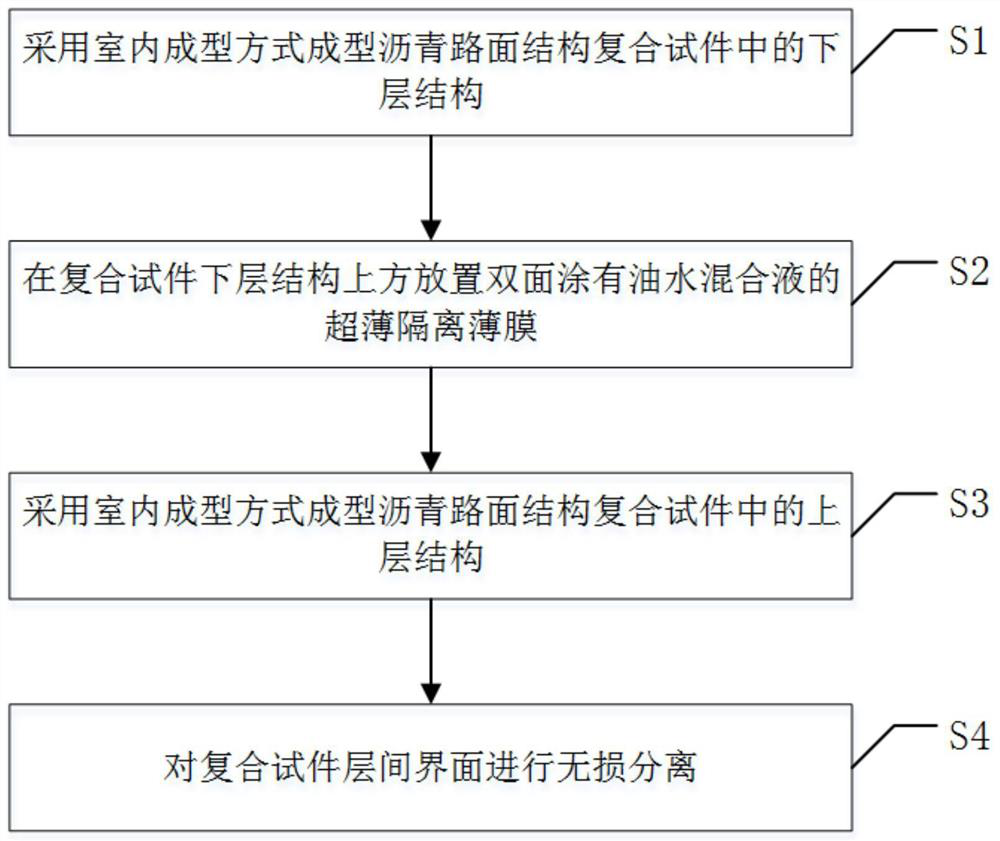

[0045] Such as figure 1 As shown, the embodiment of the present invention provides a method for non-destructive separation of interlayer interfaces of asphalt pavement structures based on indoor forming, including the following steps S1 to S4:

[0046] S1. The lower structure of the asphalt pavement structure composite test piece is formed by indoor forming method;

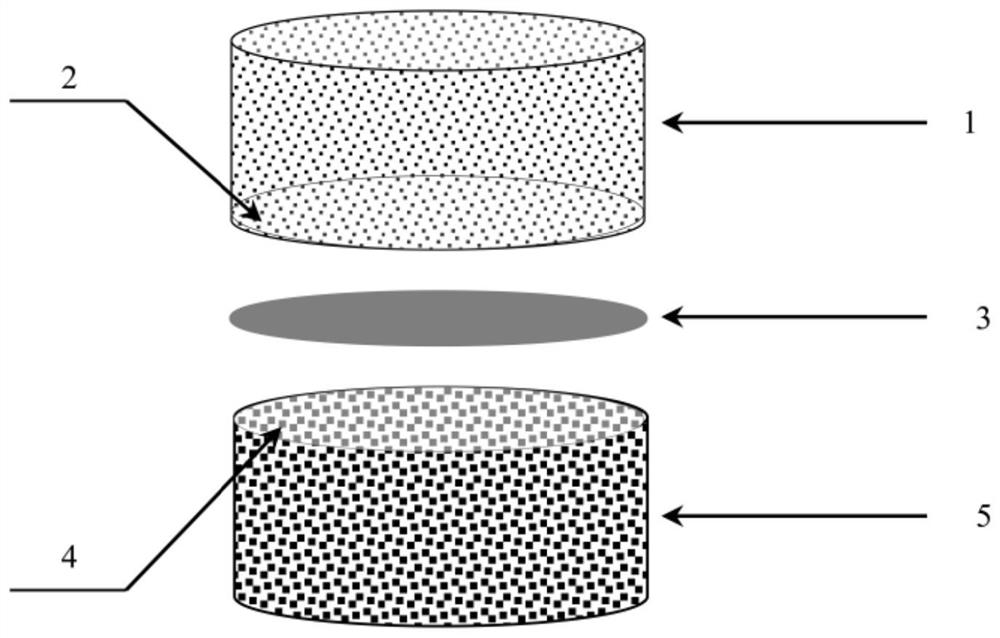

[0047] In this example, if figure 2 For the structural layer shown in middle 5, the lower layer structure in the asphalt pavement structure composite specimen includes the middle surface layer structure in the upper-middle surface layer composite specimen, the lower layer structure in the middle-lower layer composite specimen, and the lower layer-base layer Base structure in composite specimens;

[0048] Wherein, the lower structure of the composite test piece is formed by a rotary compactor, a Marshall compactor, a static pressure forming machine or a wheel rolling forming machine.

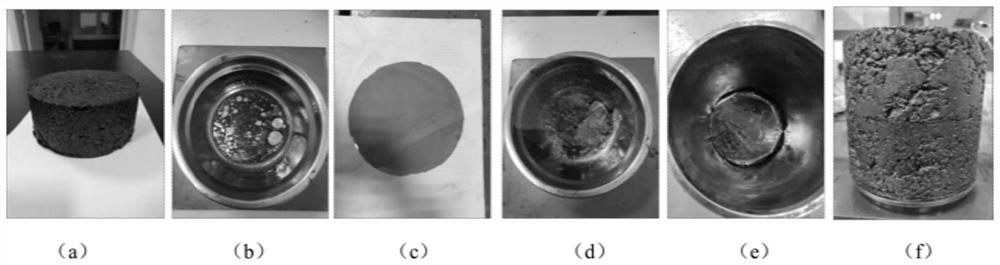

[0049] Taking the forming m...

Embodiment 2

[0072] This embodiment is similar to Embodiment 1, except that a Marshall compaction instrument is selected when the composite test piece is formed.

[0073] During the molding process of the upper and lower structural layers of the composite test piece in this embodiment, according to the operation process of the Marshall compaction instrument, weigh the corresponding asphalt mixture with a mass of 1200g (standard Marshall test piece) or 4050g (large-scale Marshall test piece), and punch each side on both sides. 50 times (standard Marshall specimen) or 75 times (large Marshall specimen). The rest of the implementation process and operation steps are consistent with Embodiment 1.

Embodiment 3

[0075] This embodiment is similar to Embodiment 1, except that the static pressure method is used when the composite test piece is formed.

[0076] In the forming process of the upper and lower structural layers of the composite test piece in this embodiment, the test piece is a cylinder with a diameter of 100 mm, and the mass of the corresponding asphalt mixture is calculated according to formula 2 according to the operation flow of the static pressure method. After the asphalt mixture is filled into the test mold, start the static pressure equipment to gradually increase the pressure from 1MPa to 20-30MPa until the test piece reaches the predetermined height.

[0077] π×r 2 ×h×ρ=m (2)

[0078] In the formula, r is the radius of the specimen, 50mm; h is the set height of the specimen, mm; ρ is the Marshall standard compaction density, g / cm 3 ; m is the mass of asphalt mixture, g.

[0079] The rest of the implementation process and operation steps are the same as in Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com