High-speed mute shunting device

A shunt device and silent technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of low power transmission efficiency, prone to failure, unstable operation, etc., to achieve high transmission power and not easy to freeze , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention is further described below in conjunction with specific embodiments:

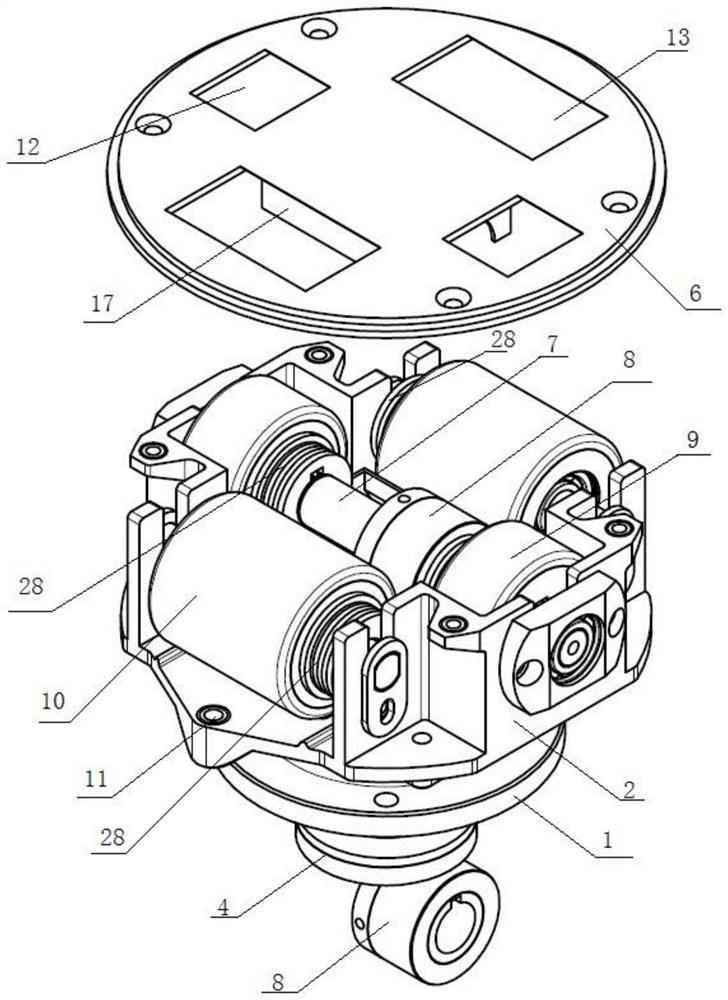

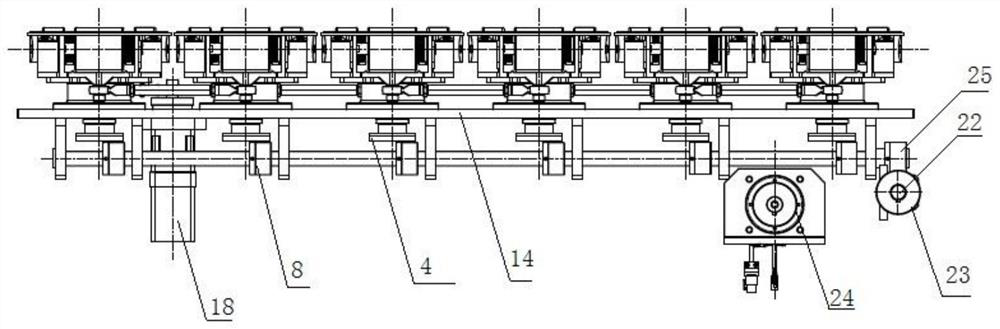

[0034] A high-speed silent shunt device, such as Figure 1-7 As shown, it includes 5 groups of shunt modules arranged side by side, and also includes a second drive unit 24 and a second transmission rod 22. The shunt module and the second drive unit 24 are all installed on the main body support 29; A driving roller 30 is installed, and it is output from one end of the splitter module to the other end during transportation. The driving roller 30 is arranged on one side of the output direction of the splitter module. The driving roller 30 is a power roller and can rotate independently; the second transmission rod 22 is horizontal It is arranged on one side of the 5-row shunt module, and the second drive unit 24 is connected to the transmission wheel 23 arranged at one end of the second transmission rod 22 through a synchronous belt. The second drive unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com