Internal cleaning mechanism and method for spiral mandrel of horizontal screw machine

A cleaning mechanism and spiral core technology, which is applied to centrifuges, centrifuges with rotating drums, etc., can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

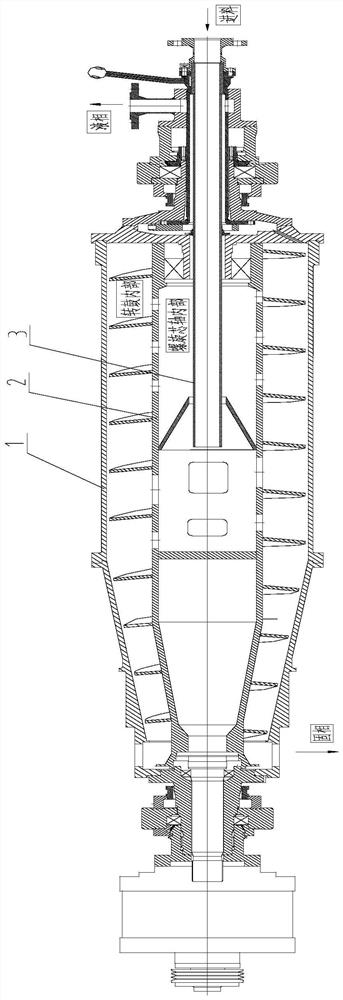

[0036] like figure 1 As shown, the existing cleaning mechanism of the decanter screw machine includes a drum 1, a screw mandrel 2 and a feed pipe 3. The screw mandrel 2 is installed inside the drum 1, and the feed pipe 3 is installed inside the screw mandrel 2. When the screw machine is cleaned, water is passed through the feed pipe 3 to clean the inside of the drum 1. However, there is a cleaning dead angle inside the screw mandrel 2, resulting in incomplete cleaning.

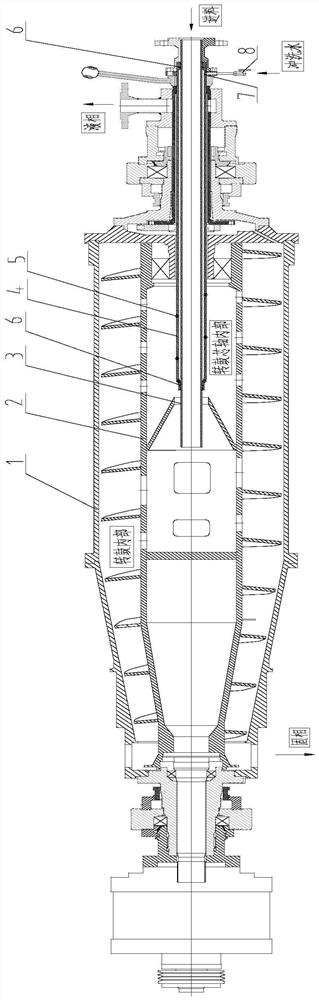

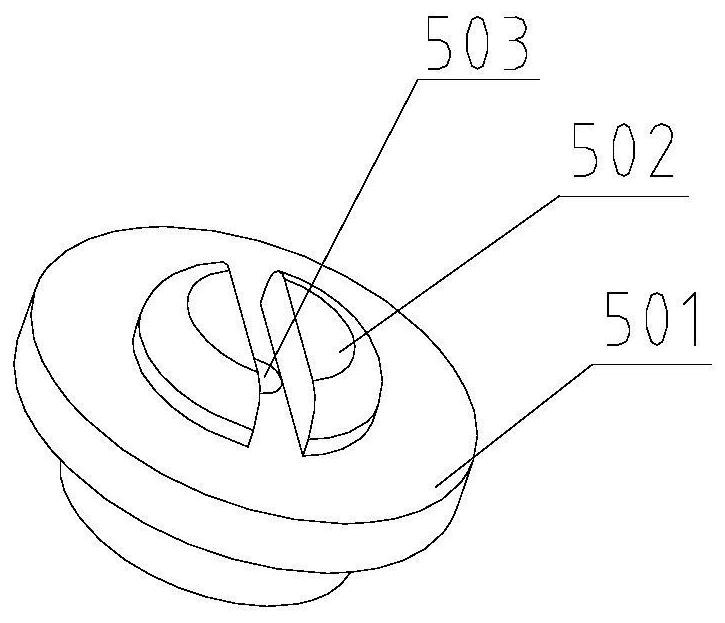

[0037] like figure 2 As shown, the internal cleaning mechanism of the screw mandrel of the horizontal screw machine includes a sleeve 4 sleeved on the feed pipe 3. The outer diameter of the feed pipe 3 is reduced from 60mm to 48mm, and the inner diameter is reduced from 51mm to 42mm. A closed cavity is formed between the material pipes 3, and one end of the sleeve pipe 4 is provided with a water inlet 404 connected to the outside world, and six cleaning nozzles 5 are arranged on the pipe wall of the sleeve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com