Scab remover for burn department

A coupling and screw technology, which is applied to surgical cutting instruments, surgical scissors, etc., can solve the problems of poor use effect, complicated operation, and vulnerable skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

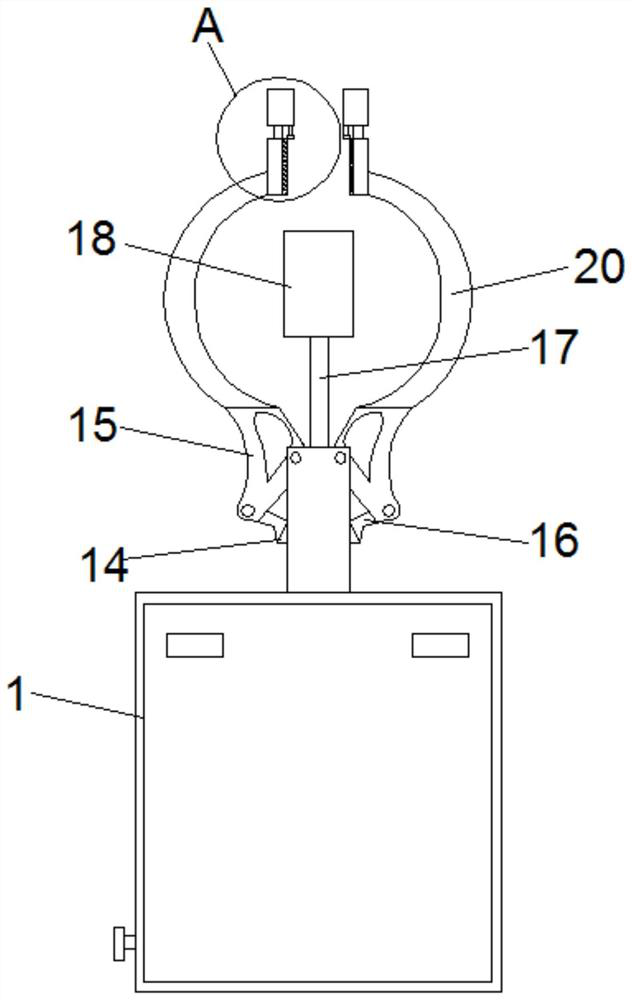

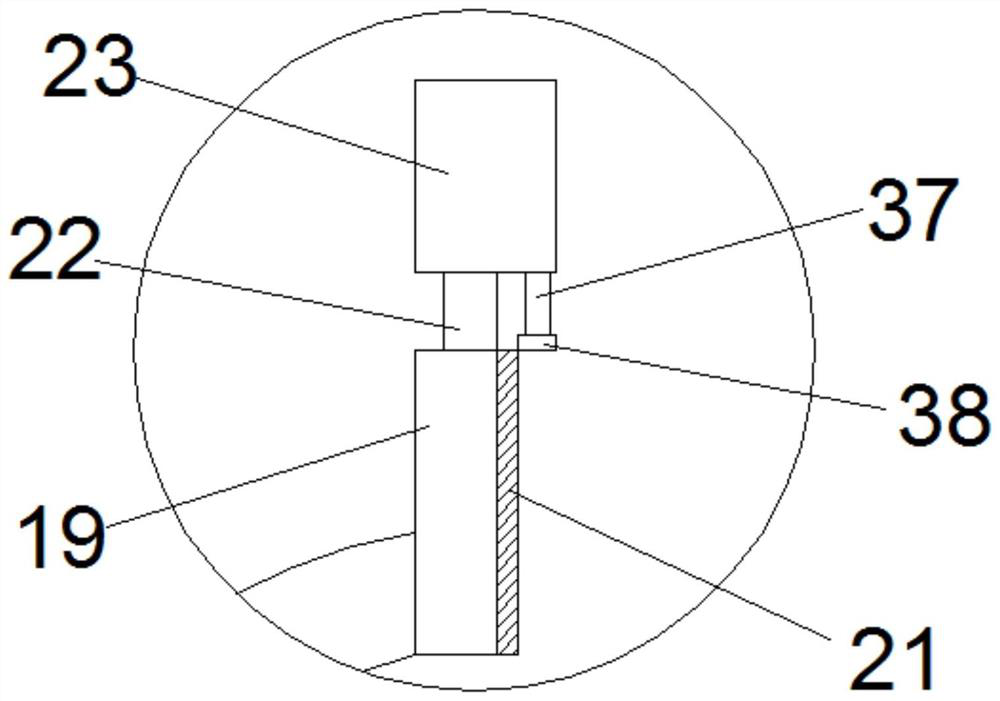

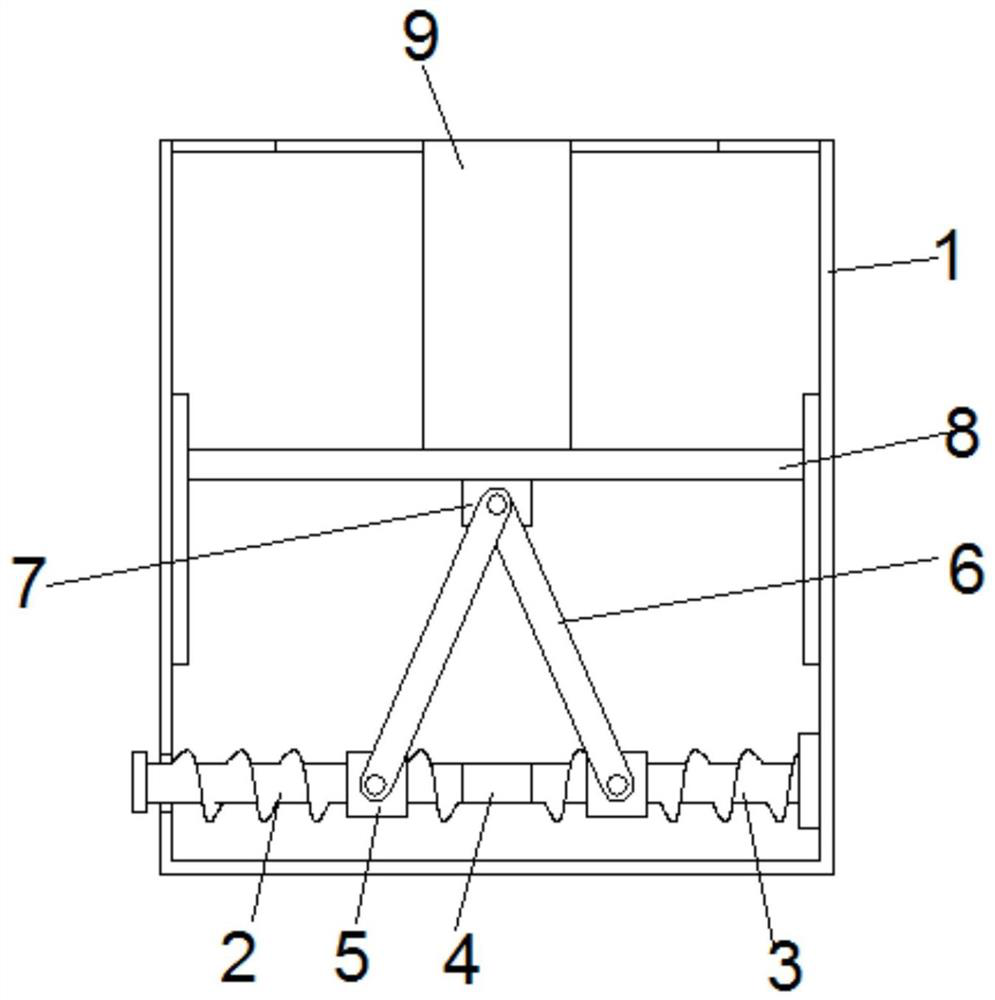

[0034] see Figure 1-9According to an embodiment of the present invention, a scab remover for burns department includes a storage box 1, a screw one 2 and a screw two 3 are arranged inside the storage box 1, and the screws on the first screw 2 and the second screw 3 are The screw thread is a reverse thread, and the screw one 2 and the screw two 3 are connected through a coupling 4, and the screw one 2 and the screw two 3 are screwed on the outside to be provided with a slide block 5, and the The slide block 5 is provided with a movable shaft one, and the movable shaft one is movably connected with a support rod 6, and the support rod 6 is far away from the movable shaft one end is sleeved on the movable shaft two, and the movable shaft Two are fixed on the fixed block 7, and the fixed block 7 is fixed on the bottom of the lifting seat 8, and the adjusting column 9 is fixed on the lifting seat 8, and the interior of the adjusting column 9 is provided with a cavity-10, and the c...

Embodiment 2

[0036] see image 3 and Figure 4 , for the screw one 2, the end of the screw one 2 away from the coupling 4 penetrates through the storage box 1 and extends to the outside of the storage box 1 with an adjustment knob. For the storage box 1 , a slide rail 1 is installed symmetrically on the inner wall of the storage box 1 , and the lifting base 8 is matched with the slide rail 1 . For the adjustment column 9, the inside of the adjustment column 9 is fixed with a baffle plate 2 41, and the screw rod 13 runs through the baffle plate 2 41, and the adjustment knob is provided to facilitate manual operation adjustment; There is a slide rail 1, which cooperates with the lifting seat 8 to carry out lifting adjustment; the baffle plate 2 41 is provided to play the role of limit support.

Embodiment 3

[0038] see Figure 7 and Figure 8 For the storage box 1, the top of the storage box 1 is provided with a storage cavity, the inside of the storage cavity is provided with a matching dustproof cover 42, and both sides of the storage cavity are provided with a cavity three 40 and an empty space. Cavity 2 43, motor 3 45 is installed symmetrically and fixedly in the cavity 3 40, the output end of the motor 3 45 is connected with the screw rod 2 46, and the outer screw connection of the screw rod 2 46 is provided with an adjustment block 49 . As for the second cavity 43 , a sliding rod 47 is fixed inside the second cavity 43 , and a sliding sleeve 48 is sheathed on the outer side of the sliding rod 47 . For the storage cavity, two slide rails are provided between the storage cavity and the third cavity 40 and the second cavity 43, and the inside of the second slide rail is provided with a matching movable block 44. Both sides of the movable block 44 are fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com