Negative-pressure heat dissipation motor

A negative pressure and casing technology, applied in the field of negative pressure heat dissipation motors, can solve the problems of unfavorable motor transportation and installation, low heat dissipation efficiency, large size, etc., and achieve the effects of shortening the total length of the motor, improving heat dissipation efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

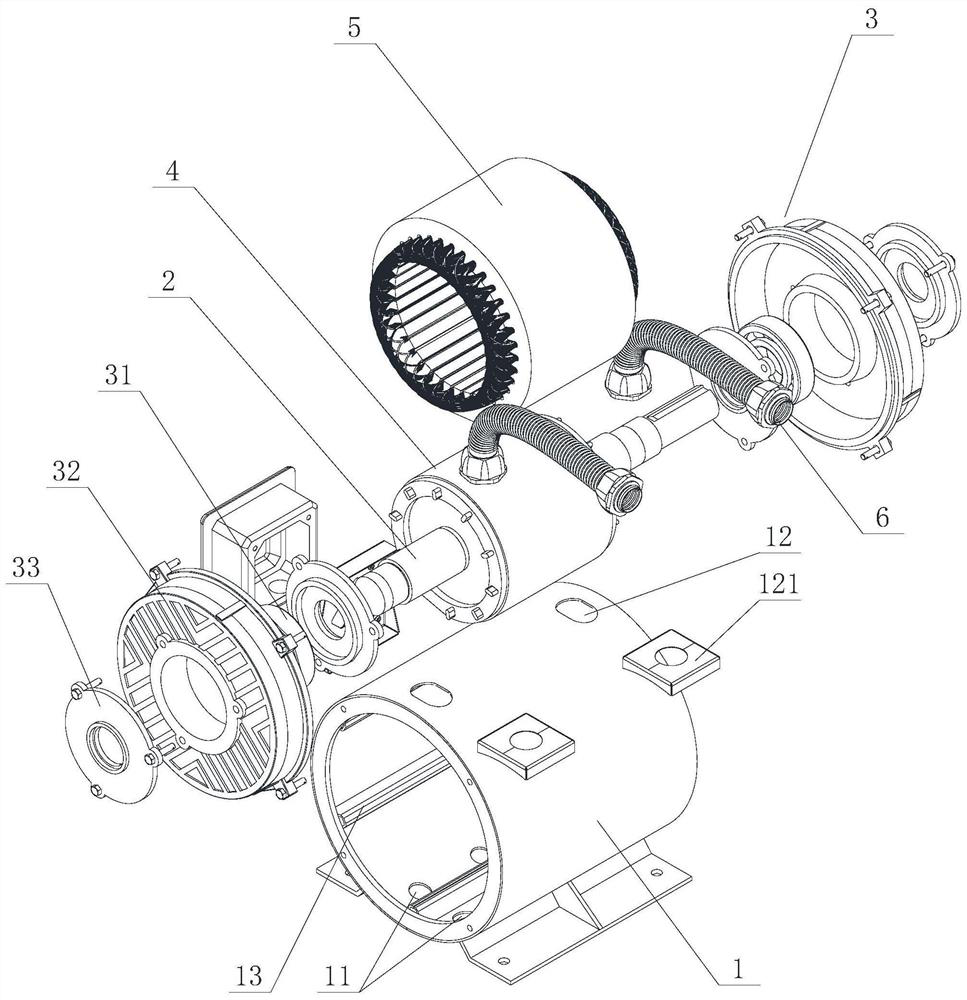

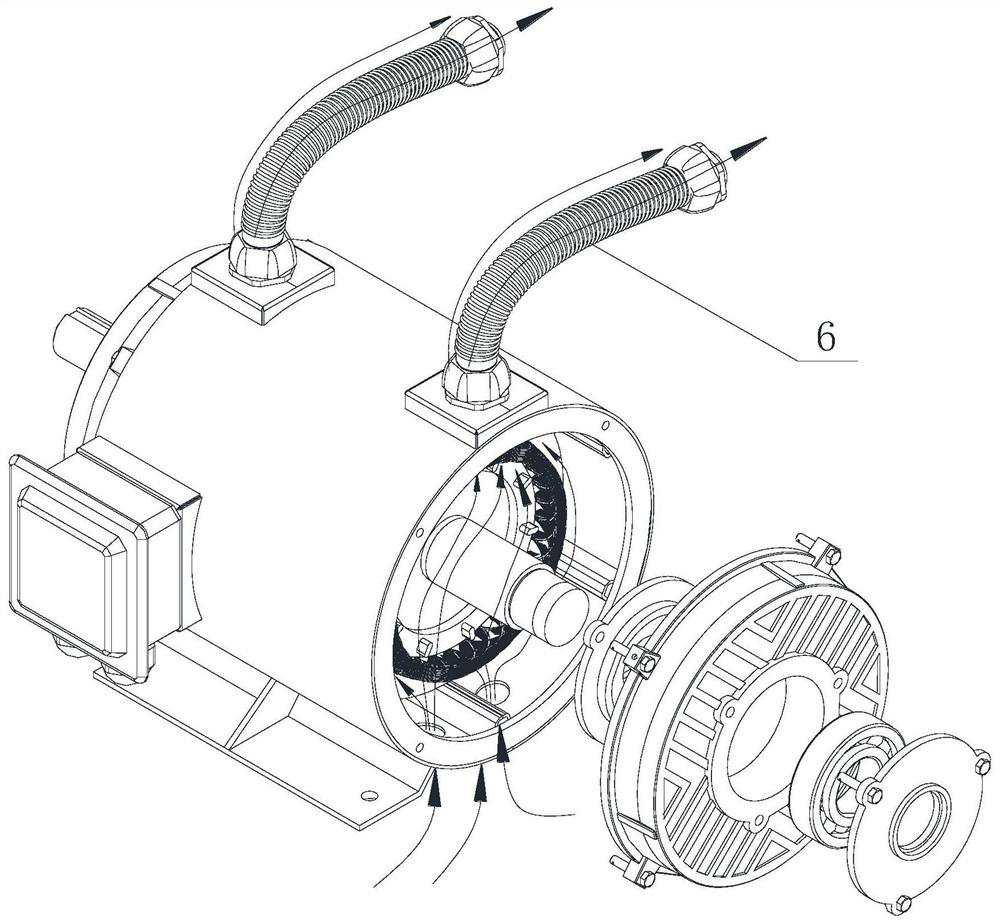

[0024] figure 1 with figure 2 It shows the first embodiment of the negative pressure heat dissipation motor of the present invention, including a casing 1, a motor main shaft 2, a shaft support group 3, a rotor 4 and a stator 5, and the motor main shaft 2 is installed in the casing 1 through the shaft support group 3 , the rotor 4 is installed on the motor shaft 2, the stator 5 is installed in the casing 1 and sleeved on the periphery of the rotor 4, the casing 1 is provided with an air inlet 11 and a negative pressure pipe 6 for leading out the air flow inside the casing 1. When the motor is running, the motor main shaft 2 is used to drive the rotor 4 to rotate, and the external low-temperature air enters the casing 1 from the air inlet 11 to air-cool the motor main shaft 2, the shaft support group 3, the rotor 4 and the stator 5, and the heat after heat exchange Air is discharged from negative pressure pipeline 6. Compared with the traditional structure, the heat dissipat...

Embodiment 2

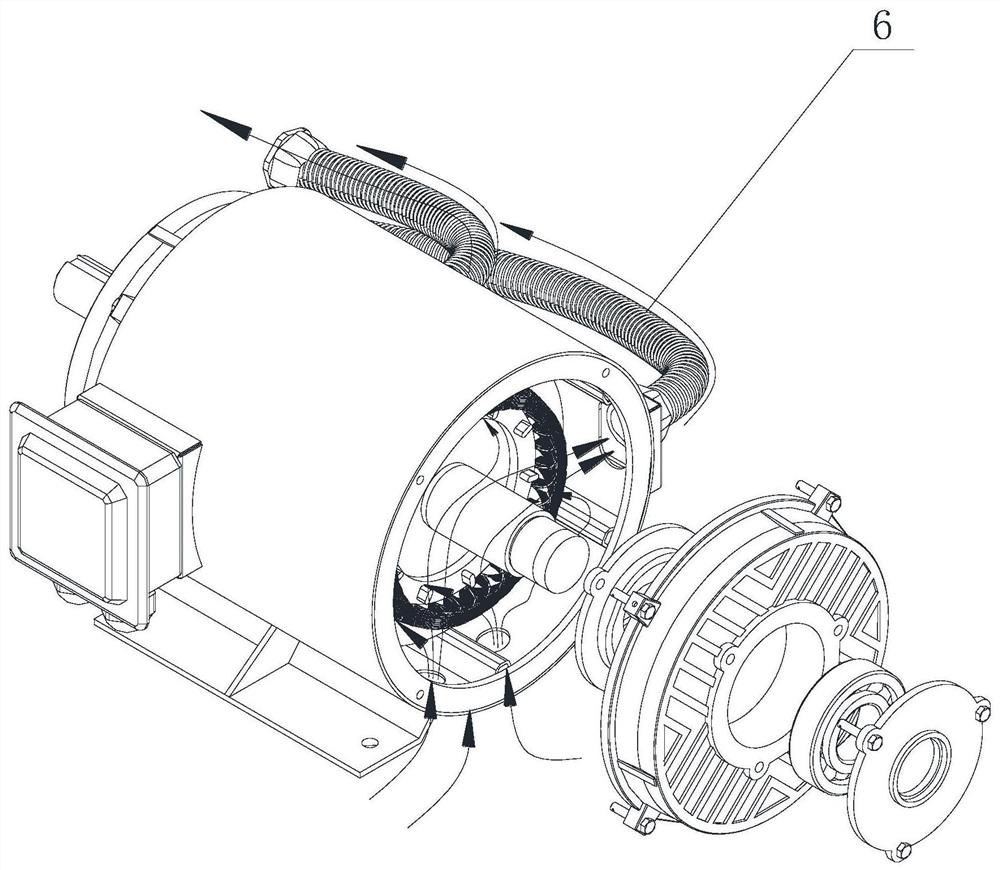

[0032] image 3 Shown is the second embodiment of the negative pressure heat dissipation motor of the present invention, the heat dissipation motor is basically the same as Embodiment 1, the only difference is that in this embodiment, the air inlet 11 is arranged at the bottom of the casing 1, and the air outlet 12 is arranged In the first quadrant area or the second quadrant area of the cabinet 1. That is to say, the exhaust mode of the upper side is formed, which can also ensure the optimization of the heat exchange space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com