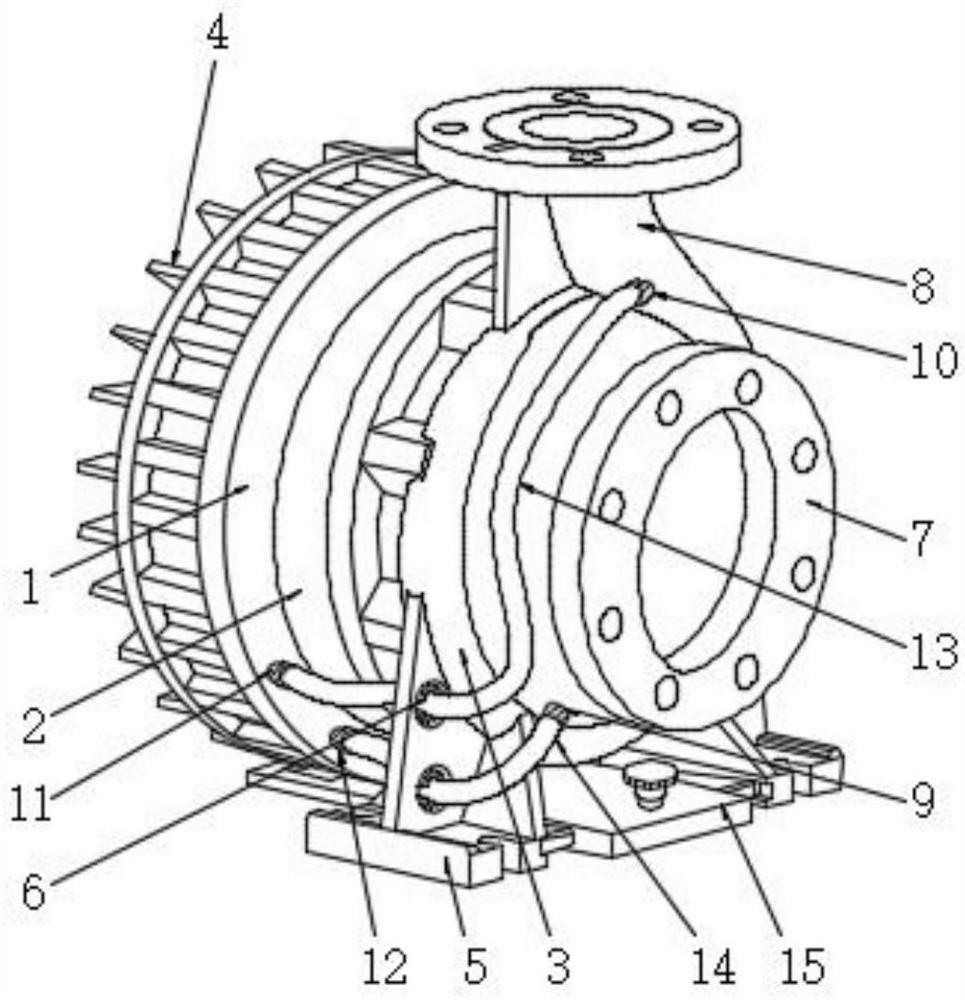

A gear variable speed disc water pump

A gear and disc type technology, applied in the field of gear speed disc type water pump, can solve the problems of poor practicability and functionality of the water pump, inconvenient adjustment of impeller torque, long pump length, etc., to improve the use environment, improve torque, reduce effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Insert the embedded plate 21 of the cooling plate 4 into the slot 24 of the disc motor 1. When the embedded plate 21 is embedded, it will push away the sealing plate 25 by compressing the first return spring 26. At the same time, the cooling plate 4 passes through the permanent magnet 23 Adsorption connection with the rear wall of the disc motor 1, the two ends of the first connecting pipe 13 are screwed to the outside of the second outlet pipe 11 and the first water inlet pipe 10, and the two ends of the second connecting pipe 14 are threaded to the second The outside of the two water inlet pipes 12 and the first water outlet pipe 9, when the first connecting pipe 13 and the second connecting pipe 14 are installed, pass through two groups of holders 6 respectively, when passing through two groups of holders 6 , change the length of the telescopic column 63 by compressing the elastic filling particles 64, expand the chuck 61 and the pad 62, and release the telescopic col...

Embodiment 2

[0057] The first water outlet pipe 9, the first water inlet pipe 10, the second water outlet pipe 11 and the second water inlet pipe 12 are tightly sealed with a sealing cover, and the sealing plate 25 is closely attached to the slot 24 driven by the first return spring 26 One side of the disc motor 1 is separated and sealed from the outside;

[0058] Pull out the block 27 of the support plate 15 from the slots 51 of the two sets of support plates 5, store the support plate 15, and keep the rotating wheel 31 from the prism block 30 up and down;

[0059] Start the disc motor 1, the connecting shaft 18 in the disc motor 1 drives the gear box 2 to work, after the gear box 2 works, it drives the impeller inside the impeller box 3 to rotate, pumping water from the water inlet valve 7 to the water outlet valve 8. Adjust the speed change member in the gear box 2, change the speed change of the gear box 2, and finally change the rotation speed of the impeller in the impeller box 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com