Composite phase-change material and preparation method thereof

A technology of composite phase change materials and mixtures, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high degree of subcooling, poor thermal conductivity, etc., to solve poor thermal conductivity, high degree of supercooling, The effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In another typical embodiment of the present application, a method for preparing the aforementioned composite phase change material is provided, the preparation method comprising: step S1, mixing materials including erythritol, graphene oxide and a solvent , to obtain a mixture; Step S2, drying and homogenizing the mixture to obtain a composite phase change material.

[0027] Graphene oxide has a layered structure, and contains a large number of oxygen-containing functional groups on the basal plane and edge of the layered structure, such as hydroxyl, carboxyl, and epoxy groups. The presence of these oxygen-containing functional groups makes graphene oxide negatively charged, while red Brought alcohol contains a large number of alcoholic hydroxyl groups. During the formation of the above-mentioned composite phase change material, the solid erythritol, graphene oxide and solvent are mixed to form a uniformly dispersed mixture, so that erythritol, oxidized Graphene can be...

Embodiment 1

[0039] Weigh about 4g of erythritol (ET) and 0.2g of graphene oxide (GO, with a particle size of 300nm) and place it in a beaker (the mass ratio of graphene oxide and erythritol is 1:20). Dissolve erythritol and graphene oxide in a mixed solvent (100 mL) with water, wherein the volume ratio of ethanol to water is 6:1, and the ultrasonic time is 6 h at an ultrasonic frequency of 200 Hz to obtain a mixture. The mixture was dried in a constant temperature oven at 80° C. for 8 hours to obtain a dried mixture, which was ground to obtain ET / GO composite phase change material 1 with a particle size of 400 nm.

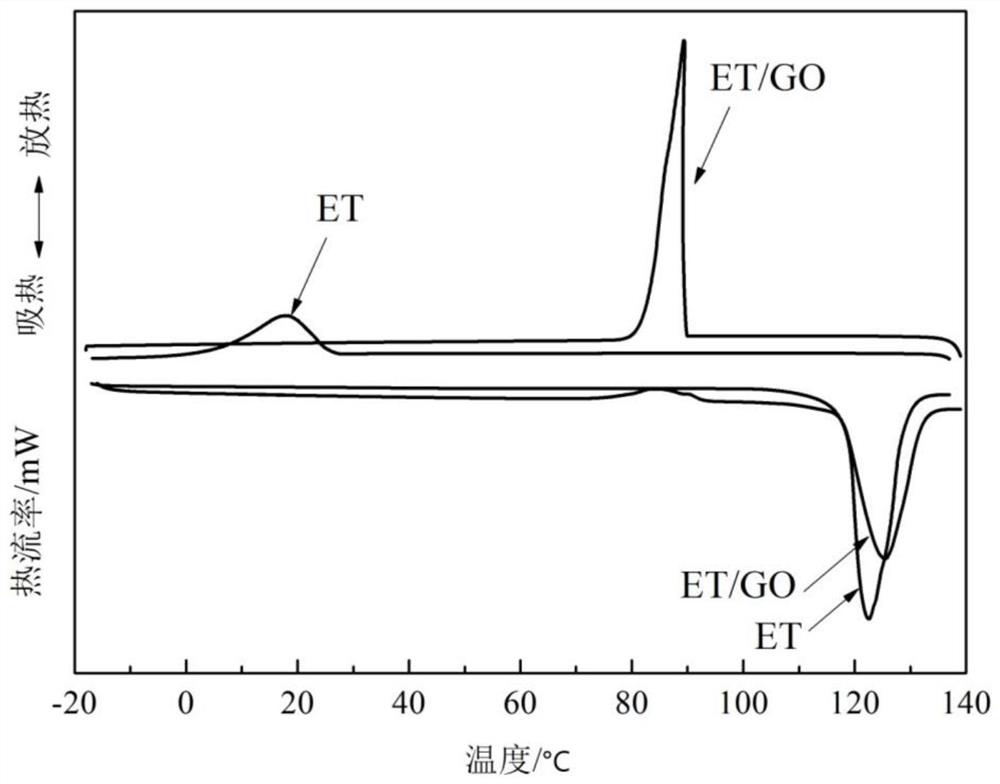

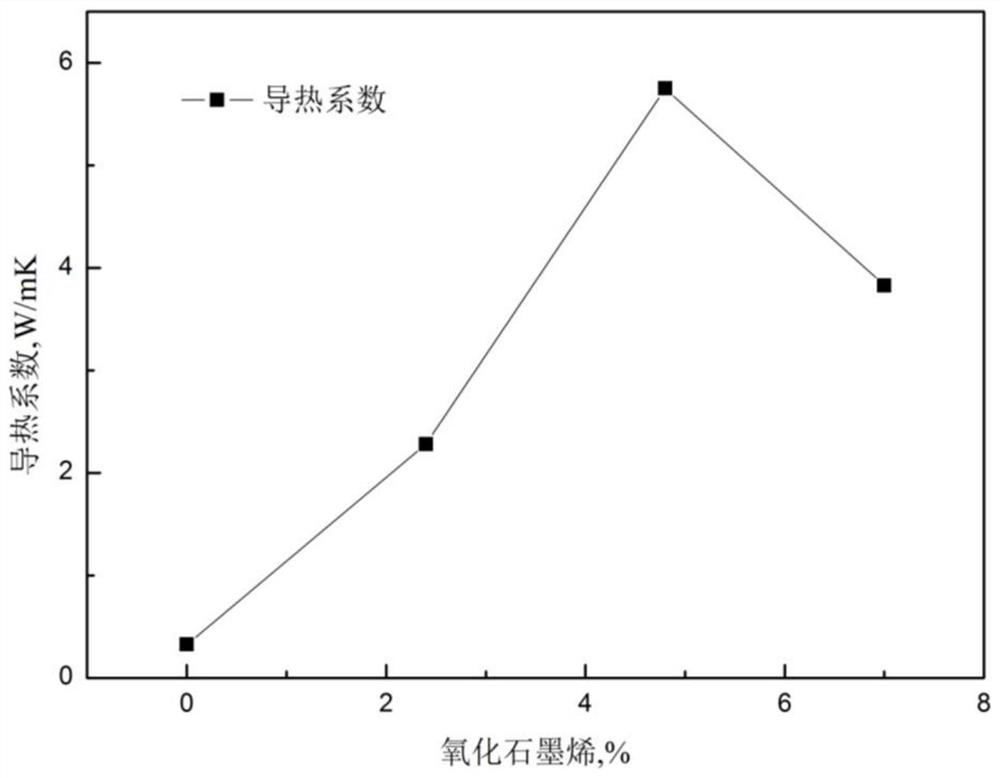

[0040] The thermal performance test DSC curve of this ET / GO composite phase change material 1 is as follows figure 1 As shown, when from figure 1 The relevant thermodynamic parameters of the ET / GO composite phase change material 1 can be obtained as shown in Table 1, and the thermal conductivity of the ET / GO composite phase change material 1 is as follows figure 2 As shown,...

Embodiment 2

[0044] The difference between Example 2 and Example 1 is that the quality of erythritol is changed so that the mass ratio of graphene oxide and erythritol is 1:16, and finally ET / GO composite phase change material 2 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com