Load fastening structure and power control box using the structure

A technology for fastening structures and boxes, applied in the fields of non-rotational vibration suppression, vehicle parts, transportation and packaging, etc., can solve the problems of high processing cost of sheet metal bent frame and cannot meet the flexible and changeable needs of the market, and achieve Improve overall strength and avoid tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

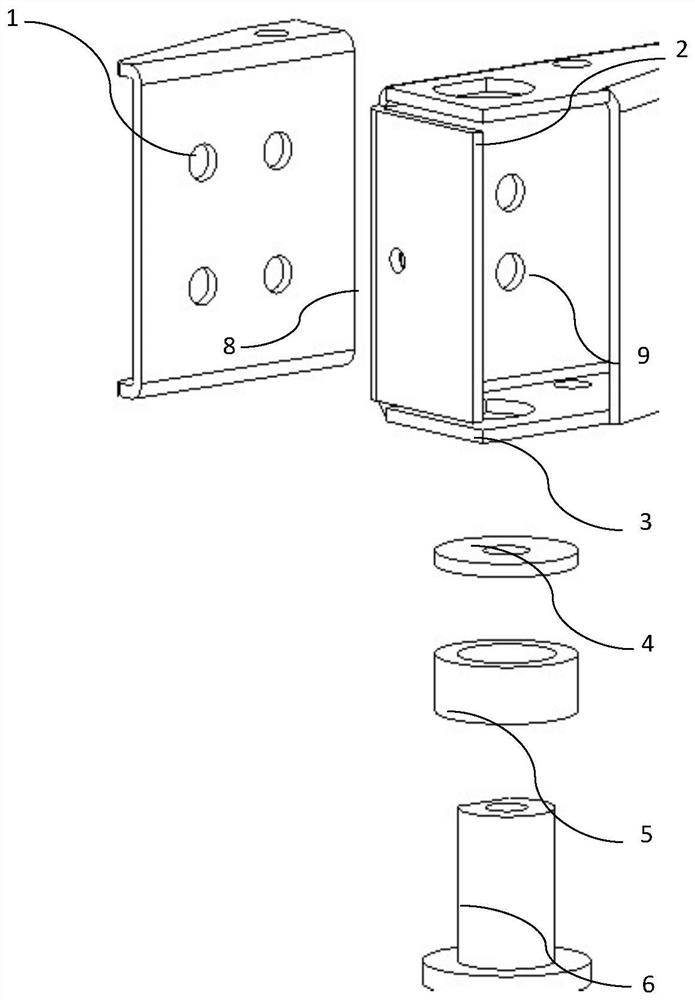

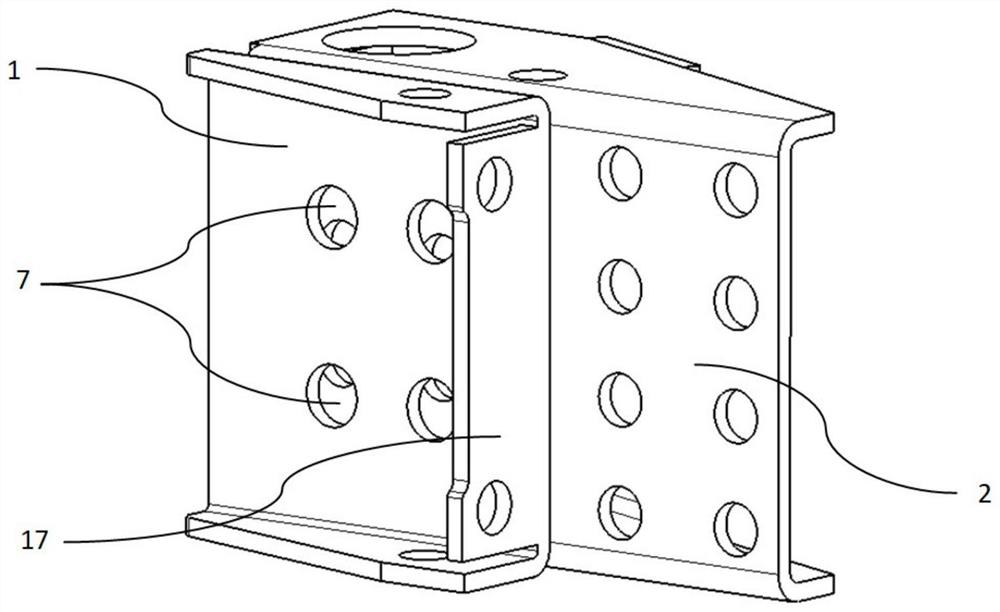

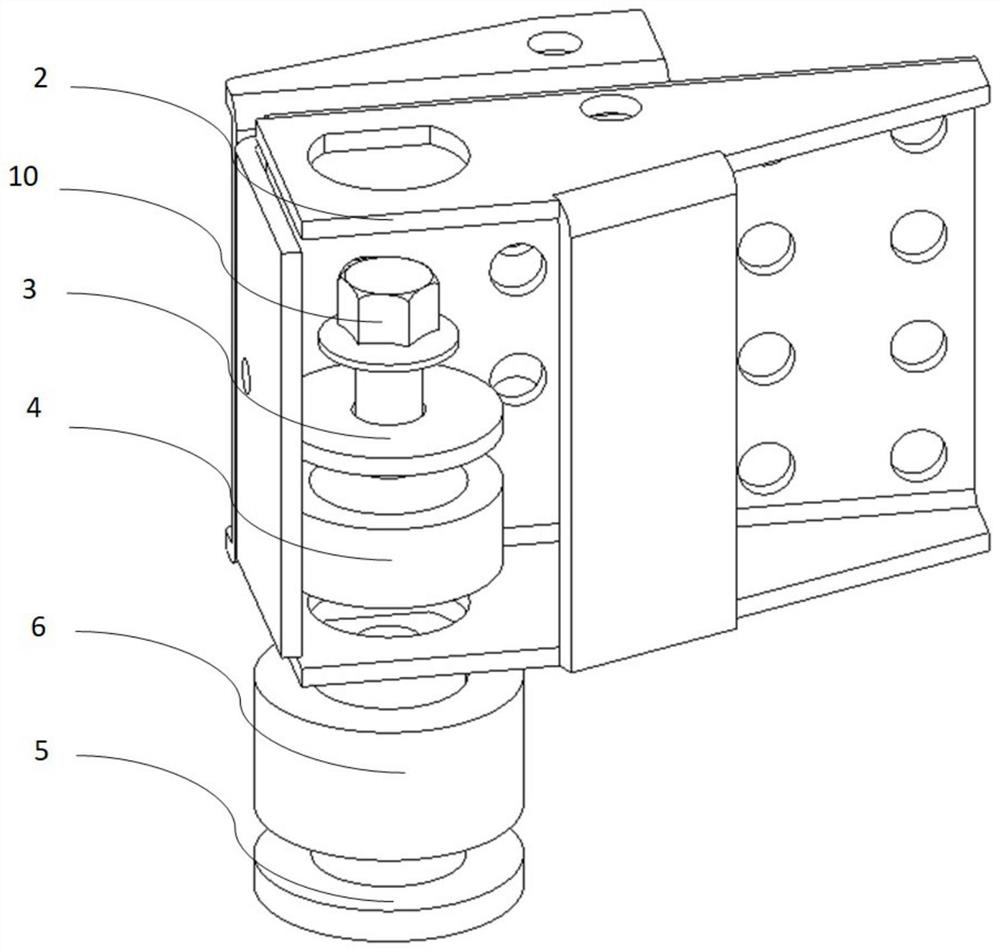

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0041] The present invention lies in: setting a load-bearing fastening structure comprising a combination of main bracket and auxiliary bracket, the mechanism is welded to each other to form an installation space with an included angle of 90 degrees, and the bolts crossing the main bracket and the auxiliary bracket horizontally and vertically are used to transmit the pressure to the The 4 fixed brackets on the outside of the 4 edges of the box body are then transmitted to the rubber shock absorbers below the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com