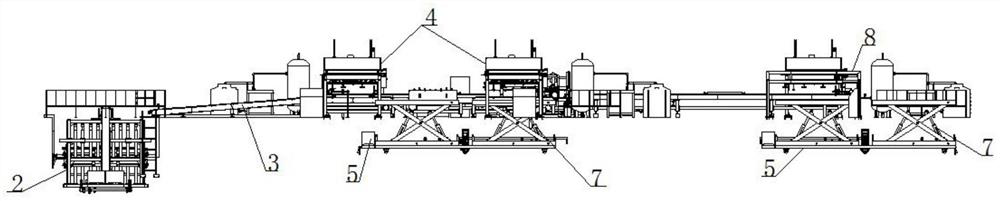

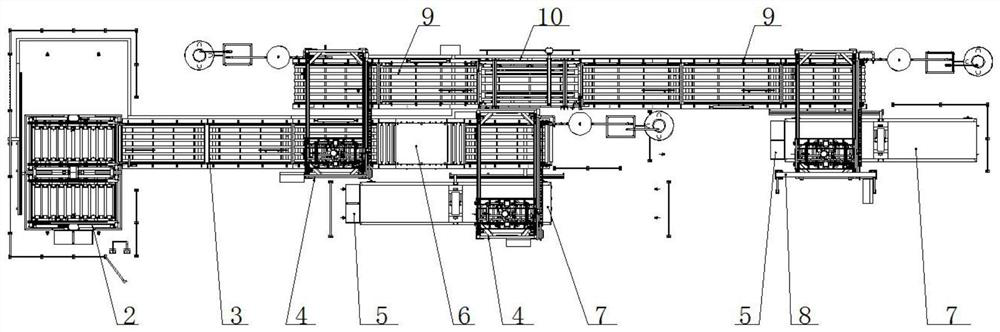

Double-line assembly production line with de-molding function

A production line and functional technology, applied in the direction of manufacturing tools, auxiliary molding equipment, unloading devices, etc., can solve the problems of lower production efficiency, lack of cleaning, and low practicability, so as to improve production efficiency, high promotion value, and improve release Die Efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

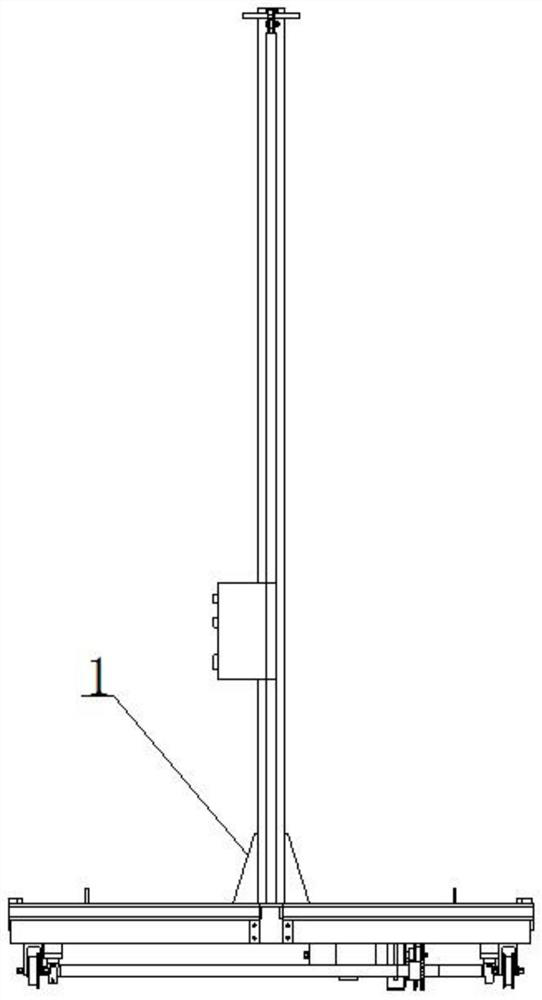

[0027] Embodiment 1, the transmission line A 3 and the transmission line B 9 are driven by the geared motor to drive the chain wheel to drive the belt on the line to provide power for the rollers, and the 2.2-meter ferry car 1 and the elevator ferry car 5 drive the rollers on the track through the motor and the sprocket , The unloader 2 drives the rollers to walk on the track through the motor and the sprocket, the hydraulic station provides power to drive the hoist to move up and down, and the motor and the sprocket on the column of the unloader 2 drive the roller to rotate to provide power for the template to be pushed out.

[0028] Implementation column 2, double-station suction cup machine 4, double-station suction cup machine unilaterally widened leg 8 is driven by a motor, and the template and product board are picked and placed through the vacuum station and vacuum suction cup, and the plate turning machine 10 is driven by the motor to realize the transmission of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com