Layered storage rack

A storage rack and side rack technology, applied in the storage rack field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, further elaborate the present invention.

[0027] The orientations involved in this specification are all based on the orientation of a layered storage rack of the present invention when it is in normal operation, and do not limit its orientation during storage and transportation, and only represent relative positional relationships, not absolute positional relationships.

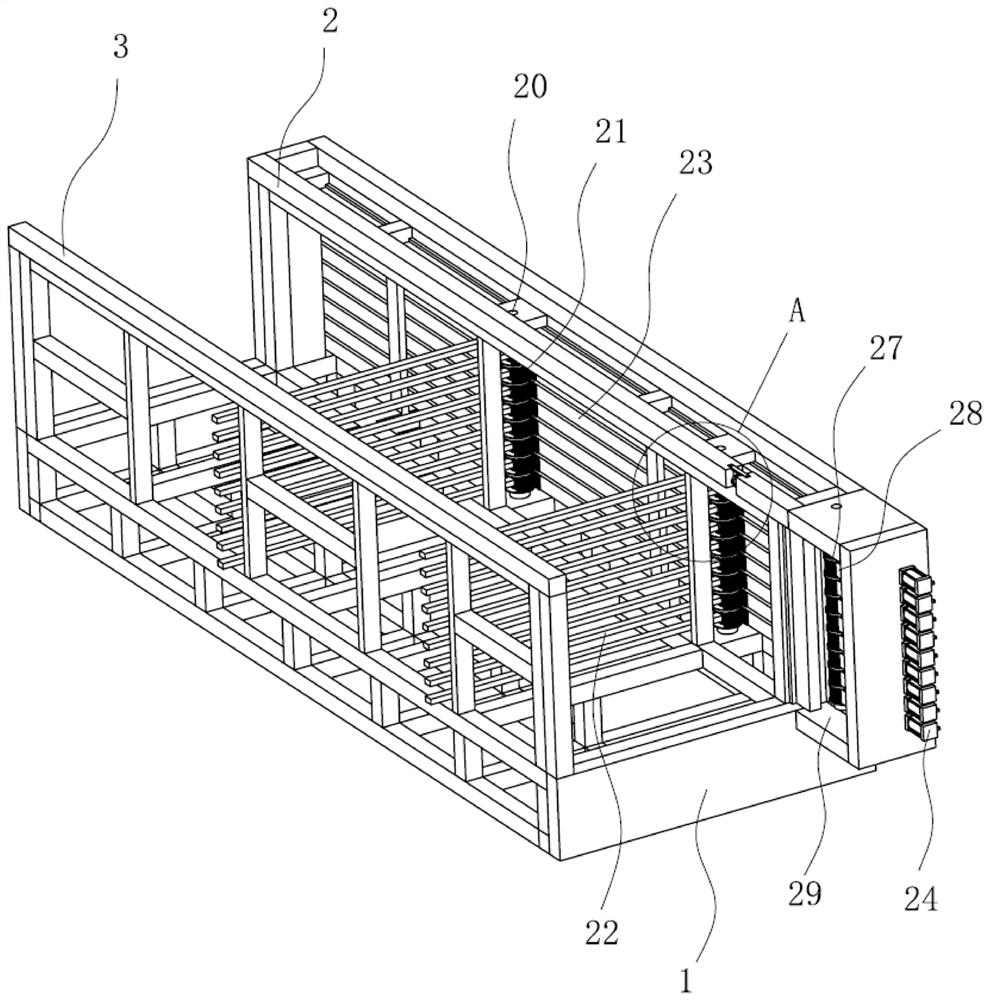

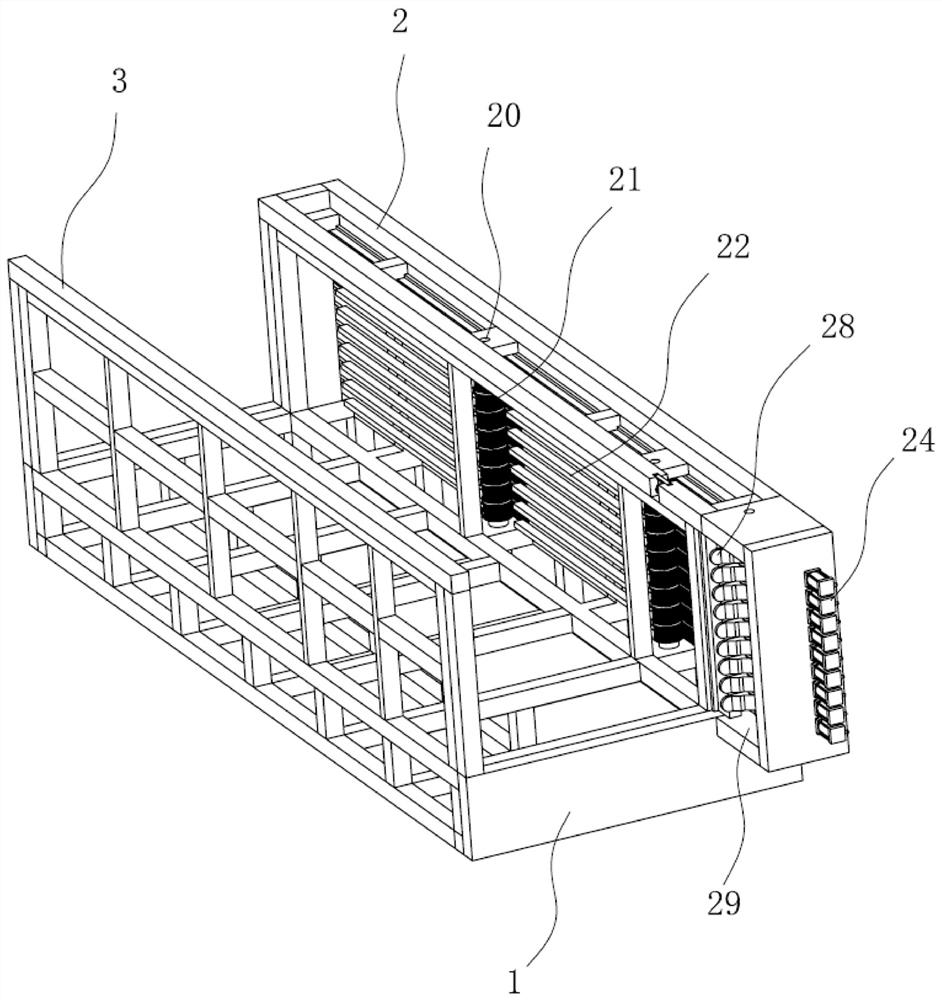

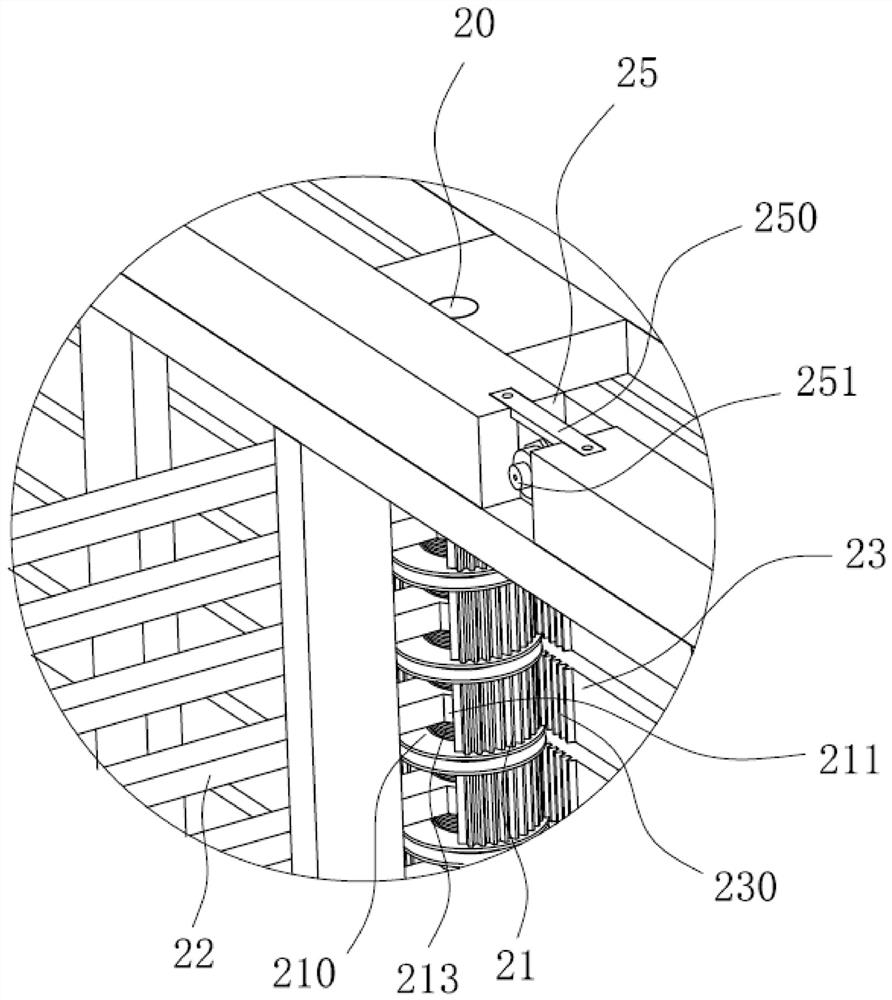

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 Commonly shown, the layered storage rack includes a bottom frame 1, a first side frame 2 and a second side frame 3 are vertically installed on the bottom frame 1, the first side frame 2 and the second side frame 3 are arranged in parallel and at intervals, and the channel beam Layers are placed between the first side frame 2 and the second side frame 3 .

[0029] Several first connecting shafts 20 are vertically fixedly installed in the first side frame 2, and several f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com