Lead ball collecting channel

A technology for collecting channels and shot put, applied in the direction of balls, sports accessories, etc., can solve the problems of waste of gravitational potential energy of shot put, uncomplicated production process, small pit of shot put, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

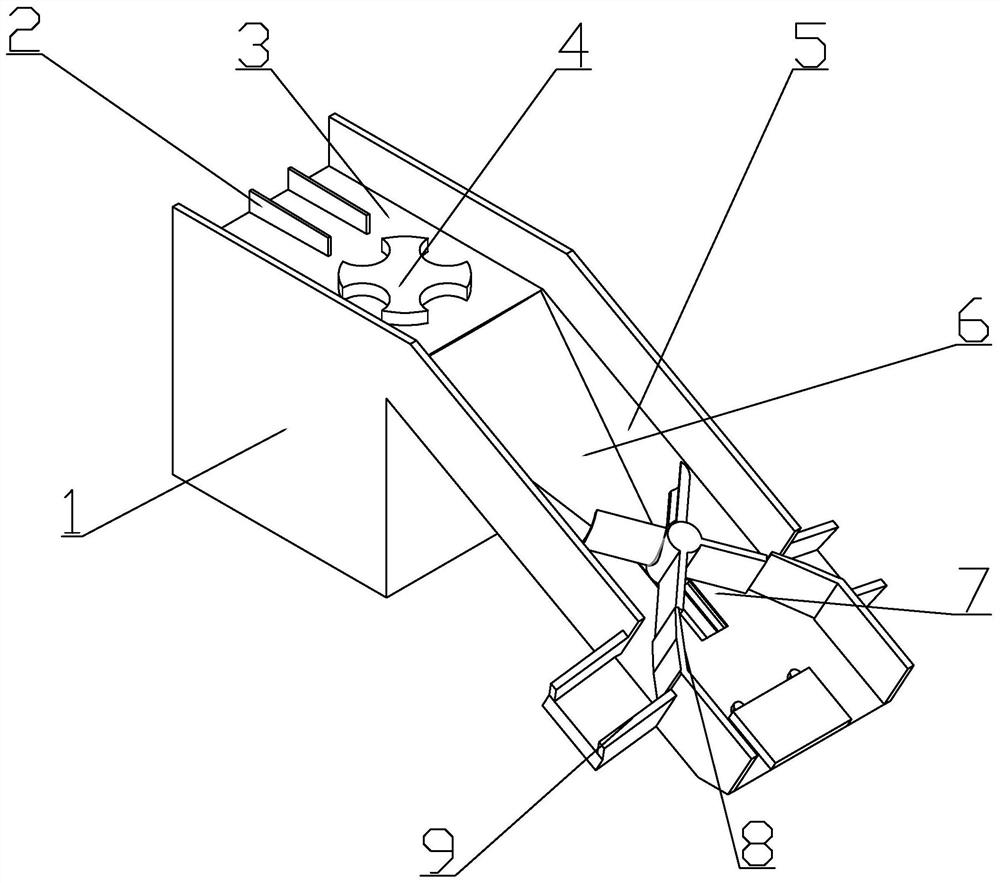

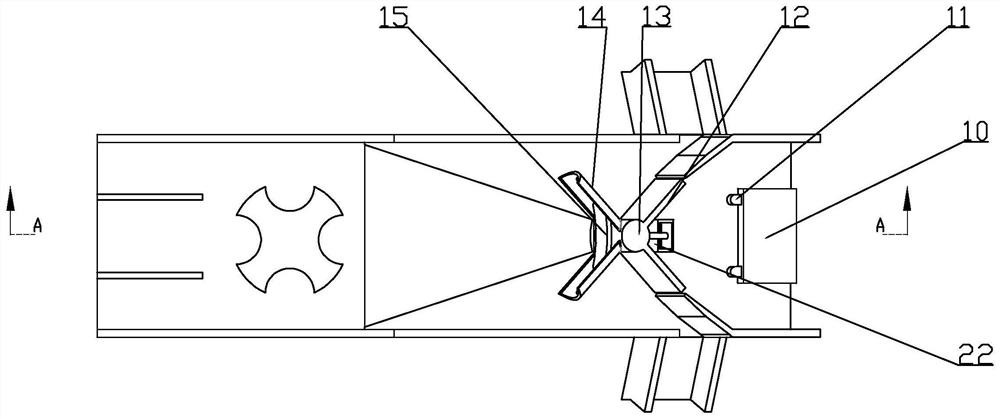

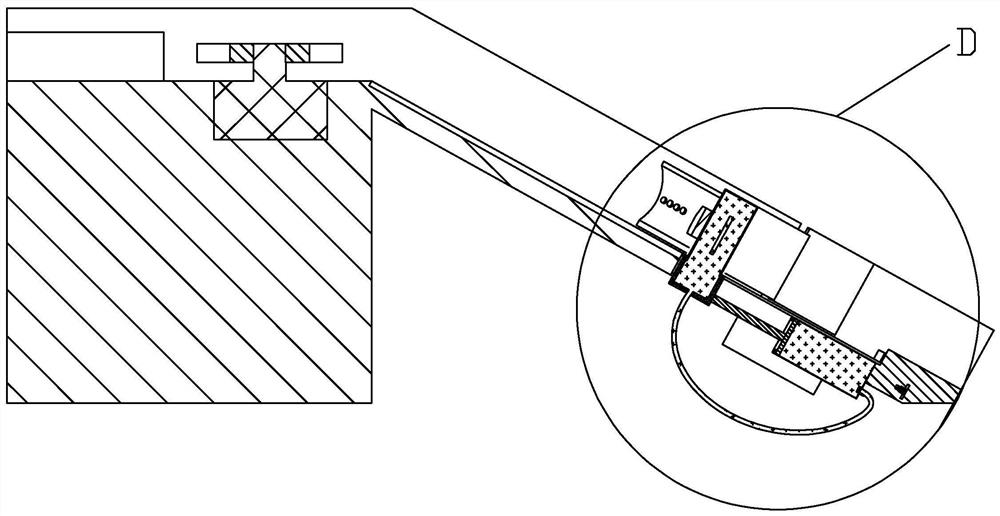

[0028] A shot collection channel, comprising a bottom box body 1, a horizontal raceway 3 is provided on the upper end of the bottom box body 1, and two left and right symmetrical stop plates 2 are arranged in the middle part of the horizontal raceway 3, and it is characterized in that the middle part of the transverse raceway 3 The rear section is provided with a feeding sheave 4, and the lower inclined slideway 5 of the horizontal raceway 3;

[0029] The buffer distribution component absorbs and converts the potential energy of the shot ball sliding down, and then distributes the shot ball left and right.

[0030] The feeding sheave 4 can separate and drop the shot balls one by one without rolling down all at once. After the shot balls fall into the inclined slideway 5, they continue to roll down and touch the buffer distribution assembly, which can not only decelerate the shot balls, It can prevent its speed from being too high to collide with the previously arrived shot dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com