Real-time monitoring system for building assembly

A real-time monitoring system and building technology, applied in the direction of using mechanical devices, measuring devices, mechanical measuring devices, etc., can solve the problems of unfavorable deformation monitoring of the main structure, inconvenient multiple detection, and difficult operation, etc., to enhance convenience and efficiency. Practicality, simplifying the process of inspection operations, and enhancing the effect of inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

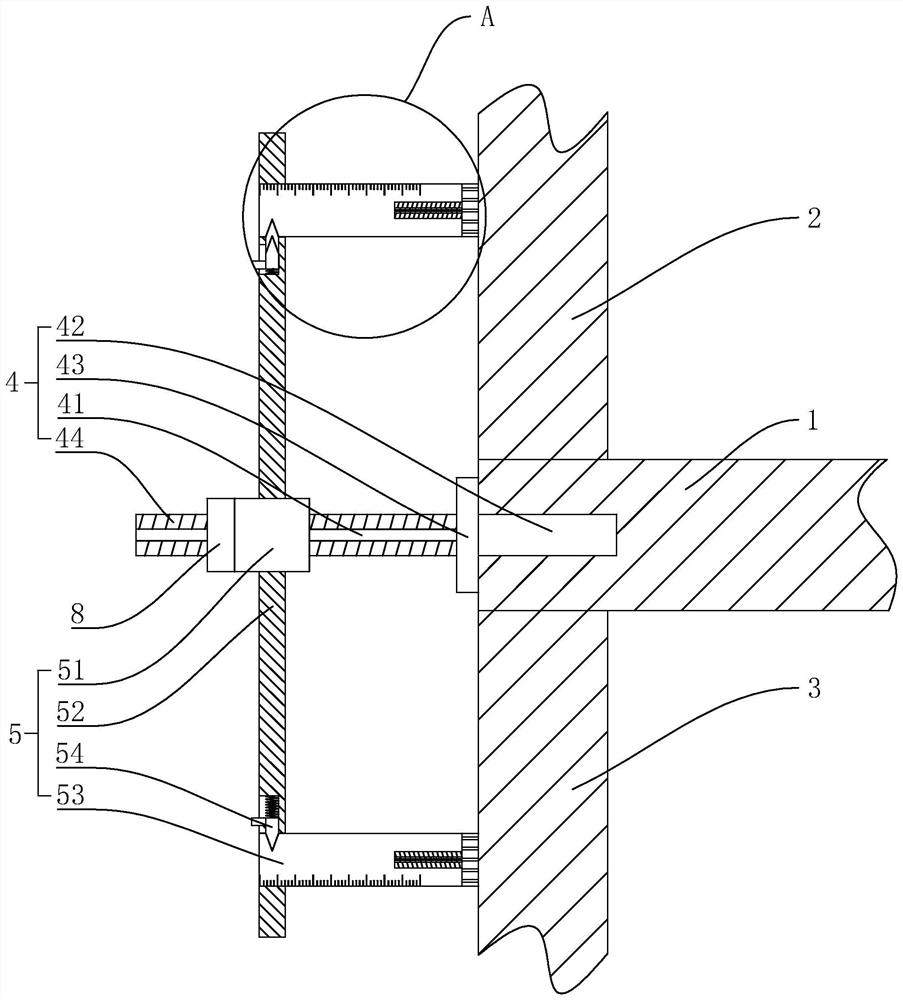

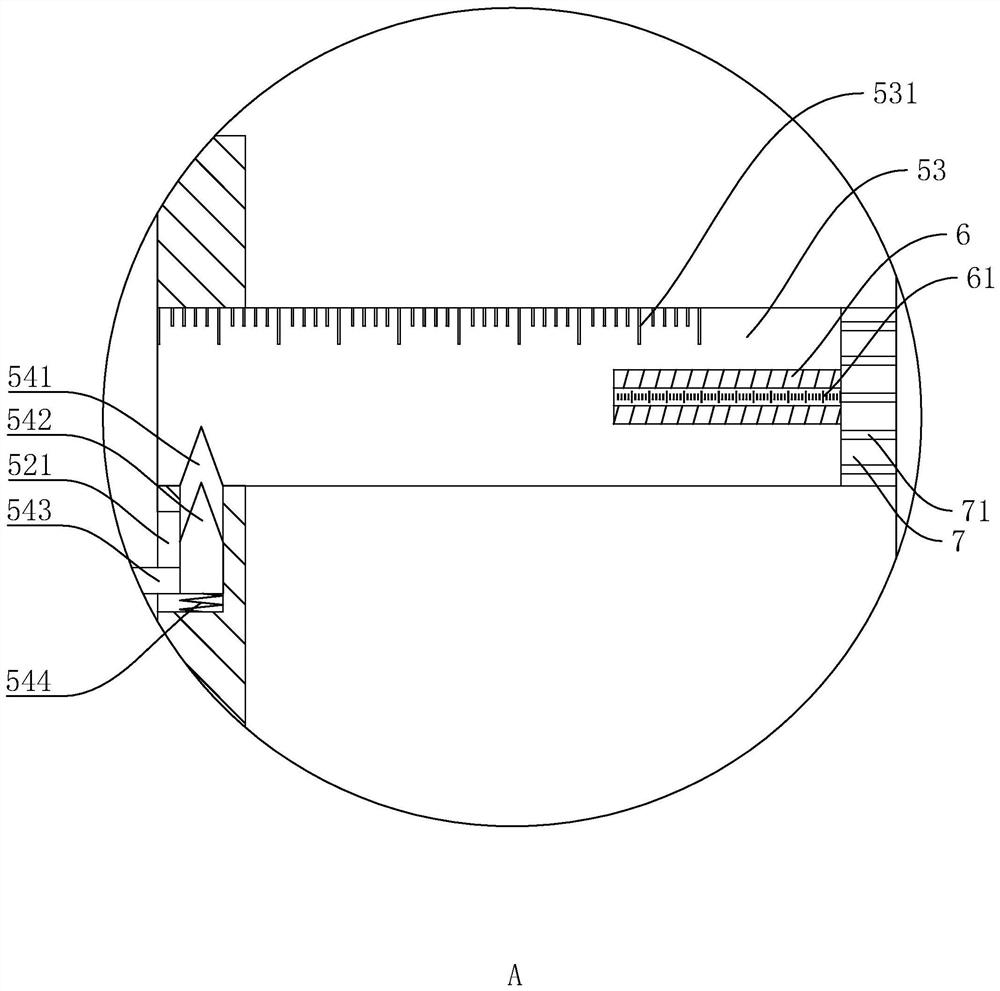

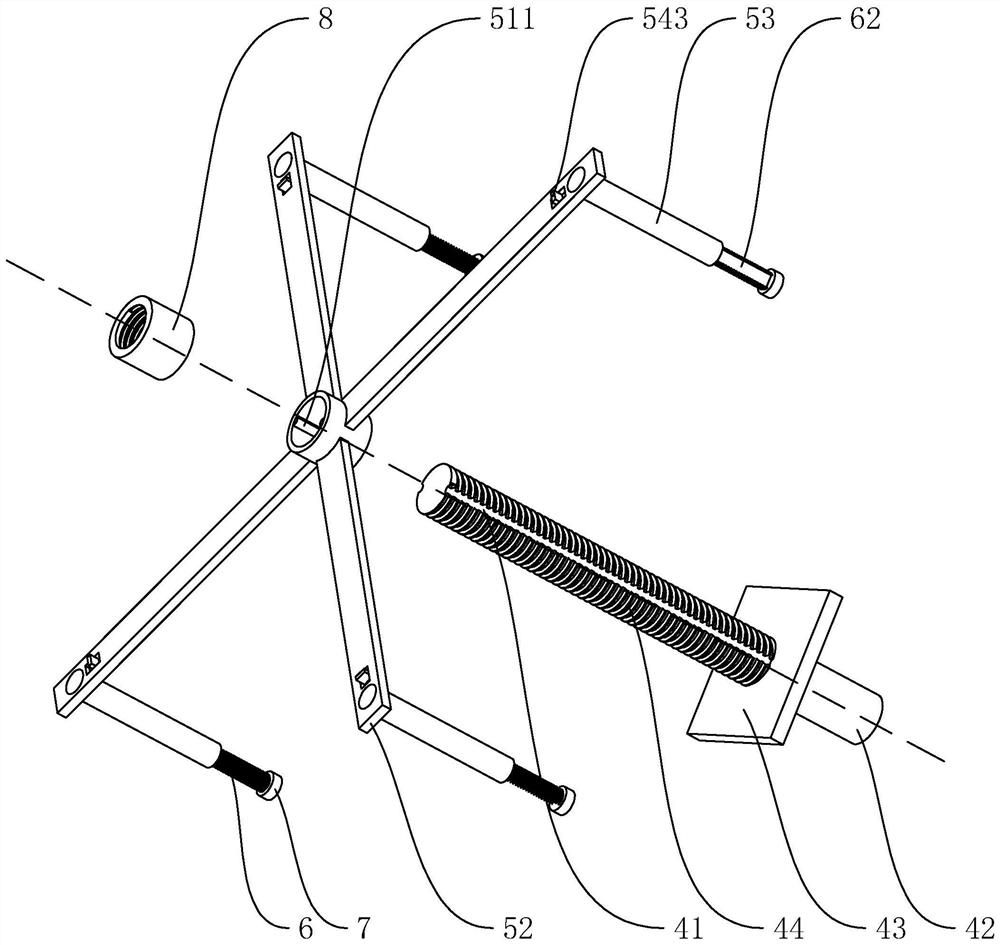

[0026] A real-time monitoring system for building assembly provided in this embodiment has a structure such as Figure 1 to Figure 3 As shown, it includes several prefabricated components. The prefabricated component includes a horizontal beam 1. The upper and lower sides of the beam 1 are respectively installed with an upper wall panel 2 and a lower wall panel 3. The inside of the beam 1 is vertically embedded with a reference rod 4. , and the reference rod 4 is arranged along the horizontal direction, the reference rod 4 includes a pre-embedded rod 42 vertically embedded in the beam 1, and the end of the pre-embedded rod 42 away from the beam 1 is vertically fixed with a vertical reference plate 43, the reference plate 43 One end away from the beam 1 is fixed with a threaded rod 44 coaxial with the embedded rod 42 .

[0027] The threaded rod 44 is slidably connected with a detection device 5 along its length direction. The detection device 5 is used to detect whether the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com