A coaxial two-way drill bit for a stable roadbed stirring pile driver

A technology for mixing pile machines and roadbeds, which is applied in the field of coaxial two-way drill bits for stable roadbed mixing pile machines. Bite force and effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

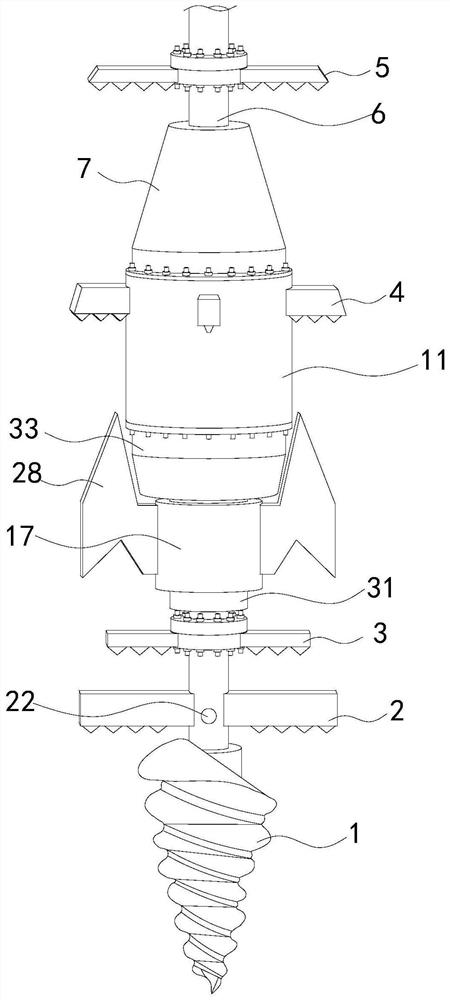

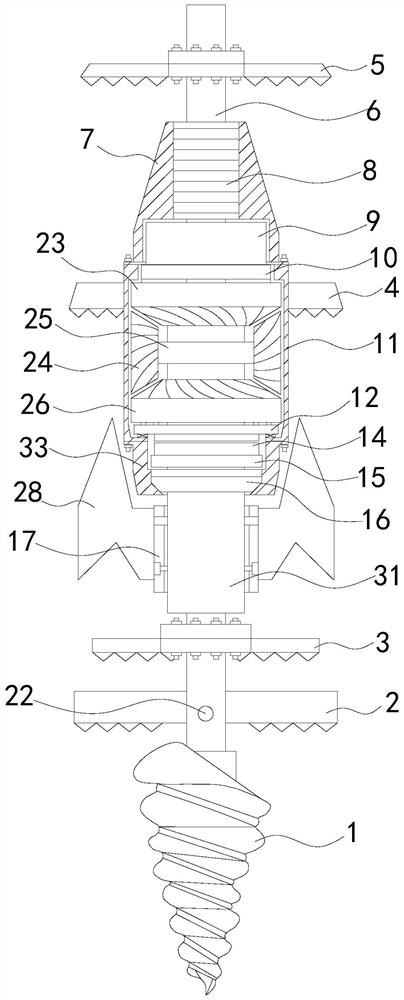

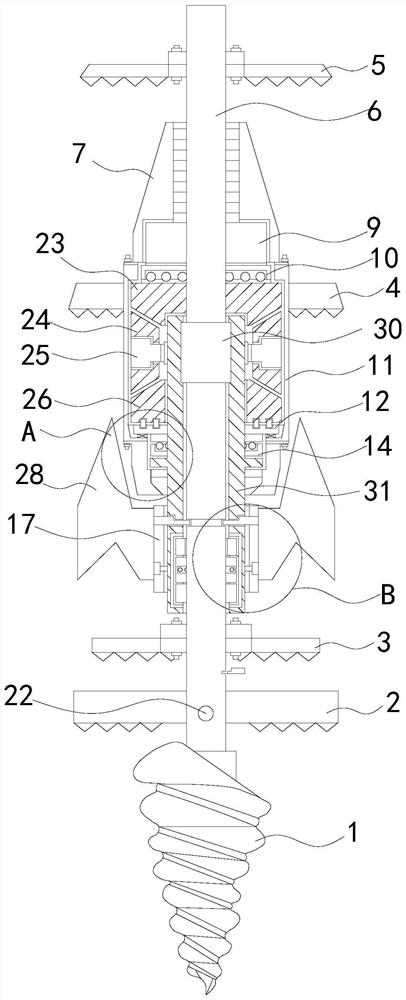

[0031] see Figures 1 to 7 , a planar and three-dimensional structure schematic diagram of a coaxial bidirectional drill bit for a stable subgrade mixing pile driver.

[0032] A coaxial two-way drill bit for a stable roadbed mixing pile machine, comprising a conical threaded mud breaker 1, the upper end of the tapered threaded mud breaker 1 is fixedly connected with an inner hollow transmission shaft 6, and the outer side of the lower end of the inner hollow transmission shaft 6 is fixedly installed with a first Blade 2, drive gear 23 is fixedly installed on the outer side of the upper part of the inner hollow transmission shaft 6, and the outer side of the lower part of the inner hollow transmission shaft 6 is movably sleeved with a positioning sleeve 31, and the outer side of the upper end of the positioning sleeve 31 is movably sleeved with a gear cross shaft 25, the gear cross The outer side of the shaft 25 is movably installed with a transition gear 24, and the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com