A kind of water-soluble photosensitive resin and its preparation method and application

A photosensitive resin and reaction technology, which is applied in the preparation of urea derivatives, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of long-term stable use, unstable mold size, and inability to show details, etc., and achieve good strength. And hardness, good temperature resistance, not easy to absorb water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. the preparation of ureido compound 1, concrete steps are as follows:

[0053]

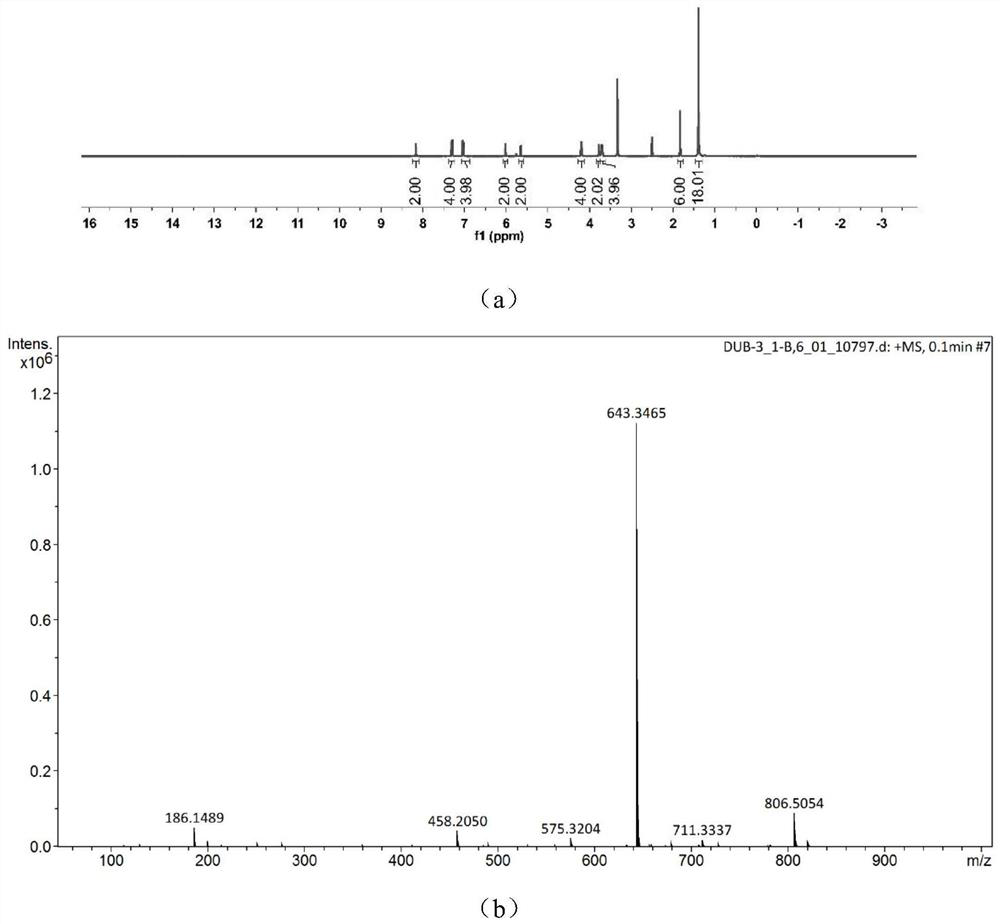

[0054] At room temperature, mix 25.02g of diphenylmethane diisocyanate and 37.04g of 2-(tert-butylamino)ethyl methacrylate. After 0.5h of reaction, a small amount of sample is taken out, and the characteristic peak of NCO has completely disappeared by infrared detection. , indicating that diphenylmethane diisocyanate has completely reacted, adding 0.01g of hydroxyanisole to the reaction system, and stirring evenly, to obtain ureido compound 1, MS m / z (ESI): 643.34[M+23], attached figure 1 It is the NMR spectrum and mass spectrum of ureido compound 1.

[0055] 2. The process of preparing photosensitive resin and photocuring 3D printing using ureido compound 1 is as follows:

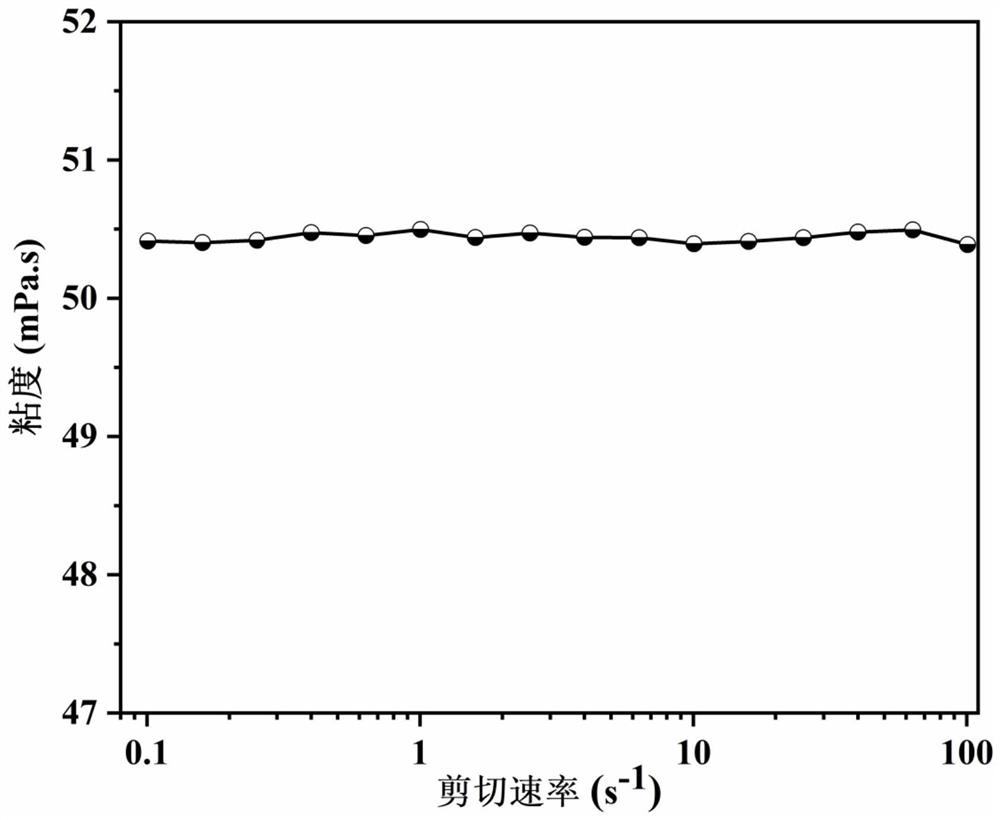

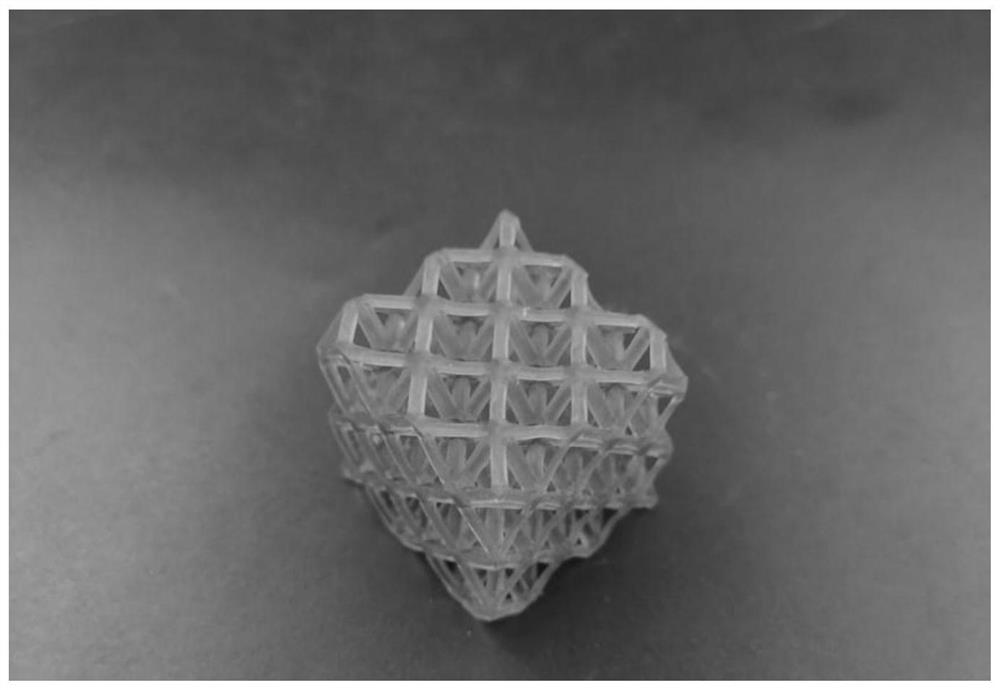

[0056] Urea-based compound 1 (5g), 4-acryloylmorpholine (95g), 2,4,6-trimethylbenzoyl-ethoxy-phenylphosphine oxide (2.5g), BASF’s Orisol Orange (0.25g) and BYK-302 (0.25g) were weighed in a beaker, stirred at 40°...

Embodiment 2

[0064] 1. the preparation of ureido compound 2, concrete steps are as follows:

[0065]

[0066] At room temperature, mix 22.2g of isophorone diisocyanate and 37.04g of 2-(tert-butylamino) ethyl methacrylate, after reacting for 0.5h, take out a small amount of sample, and use infrared detection-NCO characteristic peak has been completely disappear, indicating that isophorone diisocyanate has been completely reacted. Add 0.01g of hydroxyanisole to the reaction system and stir evenly to obtain ureido compound 2, MS m / z (ESI): 615.42[M+23].

[0067] 2. The process of preparing photosensitive resin and photocuring 3D printing with ureido compound 2 is as follows:

[0068] Urea-based compound 2 (30g), N,N-dimethylacrylamide (70g), 2,4,6-trimethylbenzoyl-ethoxy-phenylphosphine oxide (2.5g), Sudan I (0.25g), BYK-302 (0.25g) were weighed in a beaker, stirred at 40°C using a high-speed homogenizer for 20min, and finally stirred and defoamed with a vacuum planetary mixer for 10min t...

Embodiment 3

[0071] 3. the preparation of ureido compound 3, concrete steps are as follows:

[0072]

[0073] At room temperature, 16.0g of p-phenylene diisocyanate and 37.04g of 2-(tert-butylamino)ethyl methacrylate were mixed, and after reacting for 0.5h, a small amount of sample was taken out, and the characteristic peak of NCO had completely disappeared by infrared detection. It shows that the p-phenylene diisocyanate has been completely reacted, and 0.01 g of hydroxyanisole was added to the reaction system. After stirring evenly, the ureido compound 3 was obtained, MS m / z (ESI): 553.31 [M+23].

[0074] 2. The process of preparing photosensitive resin and photocuring 3D printing using ureido compound 3 is as follows:

[0075] Urea compound 3 (15g), N-vinylpyrrolidone (85g), bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide (2.5g), Sudan I (0.25g), BYK-302 (0.25g) was weighed in a beaker, stirred with a high-speed homogenizer at 40°C for 30 minutes, and finally stirred and defoamed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com