Resource recovery system device and method for desulfurization wastewater

A desulfurization wastewater and recovery system technology, applied in chemical instruments and methods, gaseous effluent wastewater treatment, multi-stage water treatment, etc., can solve the problems of single chemical treatment or physical treatment, inability to realize advanced wastewater treatment and resource recovery, etc. , to achieve the effect of avoiding secondary pollution, reducing the risk of scaling, and reducing working pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

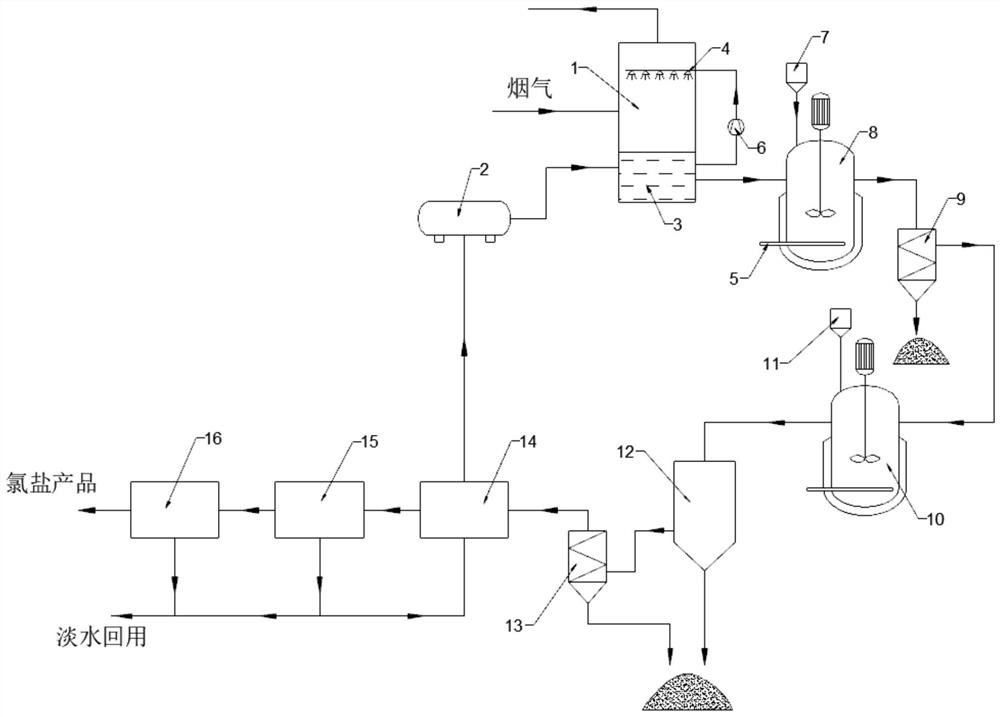

[0087] This embodiment provides a resource recycling method for desulfurization wastewater, the method comprising the following steps:

[0088] (1) The desulfurization wastewater with a salt content of 3wt% is passed into the concentrator 1, the chloride ion concentration in the desulfurization wastewater is 10000mg / L, and the sulfate ion concentration is 5000mg / L; The flue gas is sent to the concentrator 1, and the flow velocity of the flue gas in the concentrator 1 is 3m / s, and the flue gas is contacted with the desulfurization wastewater of the circulating spray to increase the concentration, and the liquid-gas ratio of the desulfurization wastewater of the circulating spray and the flue gas is 1L / m 3 , concentrate and obtain the concentrated waste liquid that pH value is 1, the concentration of chloride ion in the concentrated waste liquid is 18000mg / L, and the concentration of sulfate ion is 8000mg / L;

[0089] (2) The concentrated waste liquid is passed into the primary ...

Embodiment 2

[0094] This embodiment provides a resource recycling method for desulfurization wastewater, the method comprising the following steps:

[0095] (1) The desulfurization waste water with a salt content of 3.2wt% is passed into the concentrator 1, the chloride ion concentration in the desulfurization waste water is 11000mg / L, and the sulfate ion concentration is 5200mg / L; The flue gas at ℃ is sent to the concentrator 1, the flow velocity of the flue gas in the concentrator 1 is 4m / s, the flue gas is contacted with the desulfurization wastewater of circulating spray to increase concentration, and the liquid-gas ratio of the desulfurization wastewater of circulating spray and flue gas is 2L / m 3 , concentrate and obtain the concentrated waste liquid that pH value is 1.5, the concentration of chloride ion in the concentrated waste liquid is 18400mg / L, and the concentration of sulfate ion is 8400mg / L;

[0096] (2) The concentrated waste liquid is passed into the primary conditioning ...

Embodiment 3

[0101] This embodiment provides a resource recycling method for desulfurization wastewater, the method comprising the following steps:

[0102] (1) The desulfurization wastewater with a salt content of 3.4wt% is passed into the concentrator 1, the concentration of chloride ions in the desulfurization wastewater is 12000 mg / L, and the concentration of sulfate ions is 5400 mg / L; The flue gas at ℃ is sent to the concentrator 1, the flow velocity of the flue gas in the concentrator 1 is 5m / s, the flue gas is contacted with the desulfurization wastewater of circulating spray to increase concentration, and the liquid-gas ratio of the desulfurization wastewater of circulating spray and flue gas is 4L / m 3 , concentrate and obtain the concentrated waste liquid that pH value is 2.5, the concentration of chloride ion in the concentrated waste liquid is 18800mg / L, and the concentration of sulfate ion is 8800mg / L;

[0103] (2) The concentrated waste liquid is passed into the primary condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com