A vacuum equipment for vacuum welding or annealing of semiconductor chips

A technology of vacuum welding and vacuum equipment, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of input deviation of heavy-duty high-precision products, adding pressing devices, and pressing and tightening hinge parts. Convenient automatic loading and unloading, increase pre-compression force, easy vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the implementations shown in the accompanying drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structures of these implementations, etc. Effective transformation or substitution all belong to the protection scope of the present invention.

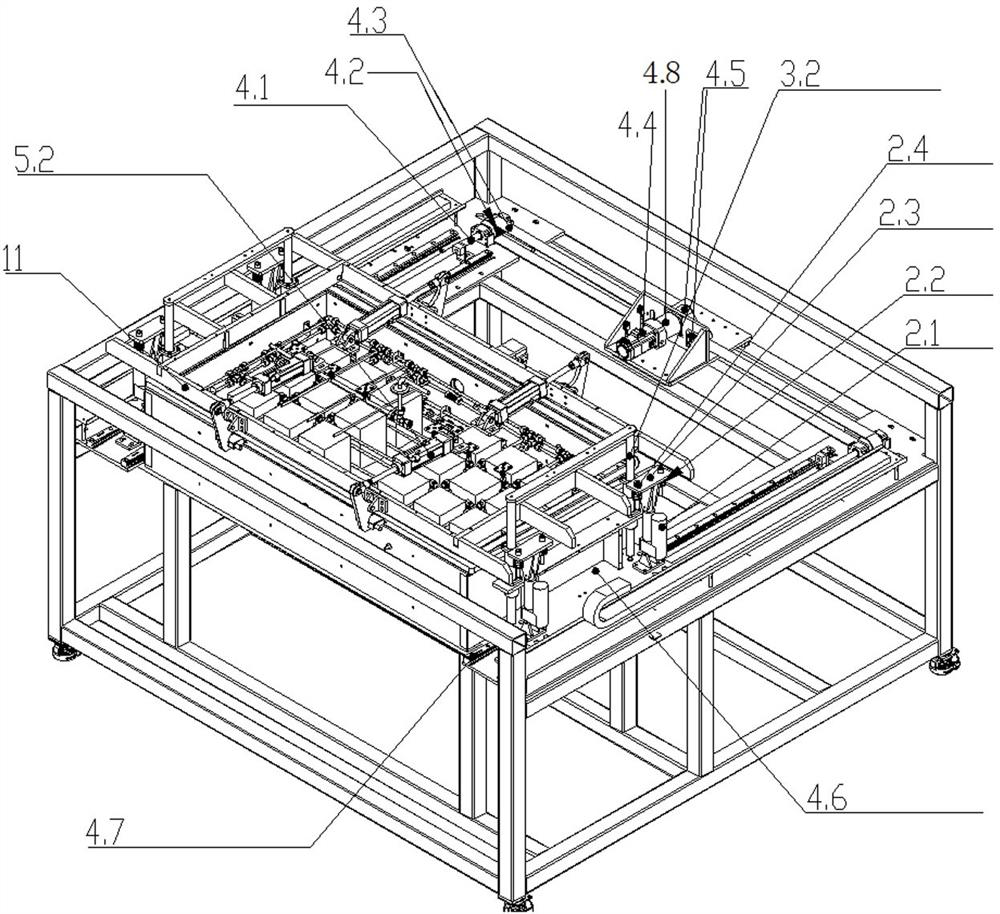

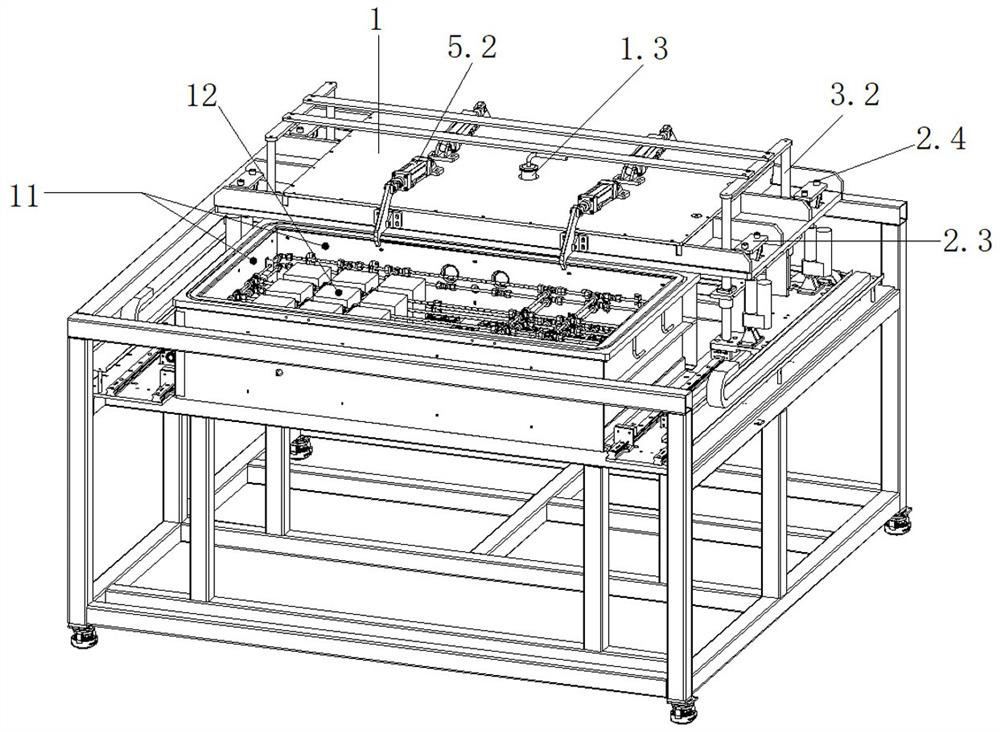

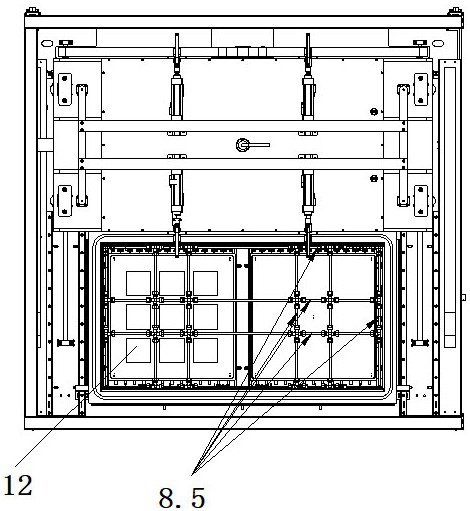

[0041] Such as figure 1 , figure 2 As shown, a vacuum equipment for vacuum welding or annealing of semiconductor chips includes a vacuum chamber 11 and a vacuum chamber upper cover 1, and also includes:

[0042] a translation mechanism, the translation mechanism is connected with the vacuum chamber upper cover 1, and can drive the vacuum chamber upper cover 1 to move horizontally relative to the vacuum chamber 11;

[0043] Lifting mechanism, the lifting mechanism is connected with the upper cover 1 of the vacuum chamber, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com