High-precision flow valve based on air detection

An air detection, high precision technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

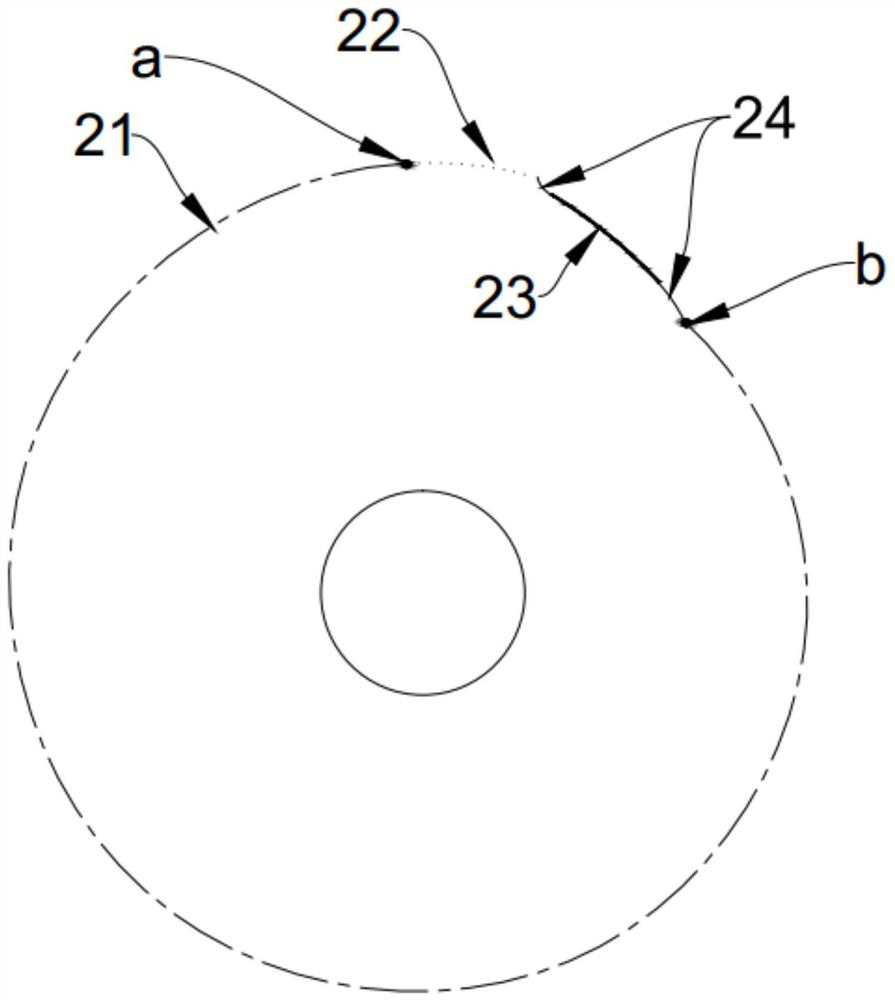

[0031] In the technical scheme of embodiment two, at the smaller end of the Archimedes spiral line segment-201 diameter ( Figure 6 When point d in the middle) is located outside the air outlet 6, the flow rate is maximum. The variation range of the spool in this solution is a gradual and continuous linear variation between the maximum value and the peak value.

[0032]The Archimedes spiral of technical scheme of the present invention is prior art, and it is to assume a point (as Figure 8 point 102) in a straight line (such as Figure 8 move outward at a constant speed on the middle line 100), and at the same time, the point 102 rotates around the inner endpoint of the line 100, and finally rotates to the position of point 101, forming the Figure 8 In the Archimedes spiral segment 200, the movement angle of the Archimedes spiral segment 200 here is less than 360 degrees, which is suitable for the design of the spool in the technical solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com