Assembly type door leaf and assembly method thereof

A prefabricated, door leaf technology, applied in door leaf, window/door, soundproof door/window, etc., can solve problems such as difficult processing, inconvenient edge sealing on the side of the door leaf, and the thickness and width of the door leaf cannot be adjusted according to the requirements of the house type, etc. Achieve the effect of meeting the strength and impact resistance requirements, convenient and fast operation, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

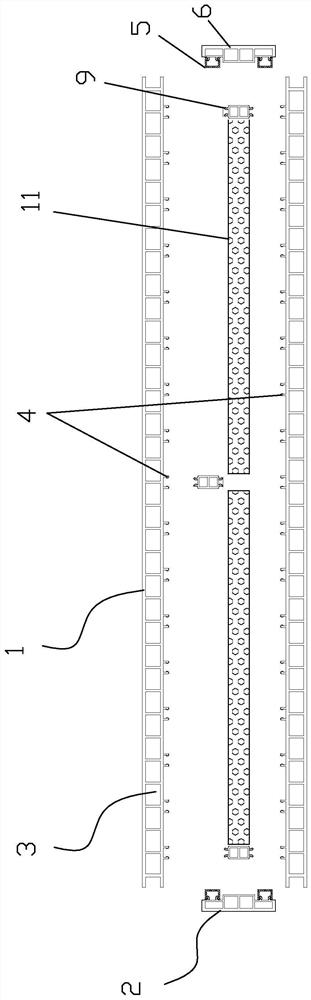

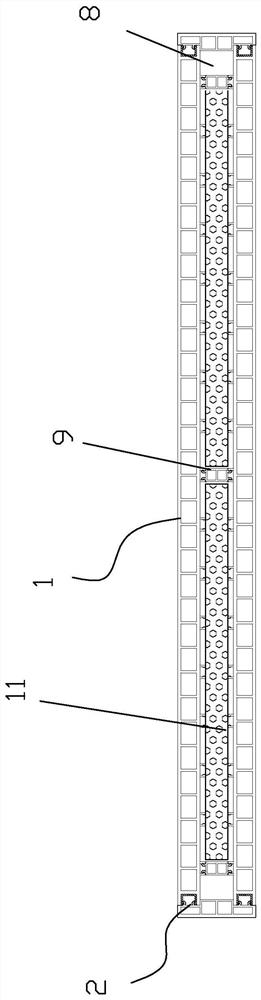

[0049] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 In the illustrated embodiment, an assembled door leaf includes:

[0050] The door panel 1 is used for card connection to form the main part of the door;

[0051] The door leaf side seal assembly 2 is connected with the door leaf panel 1 in a plug-in type, and is used to realize the side plug-in type sealing of the door leaf panel 1;

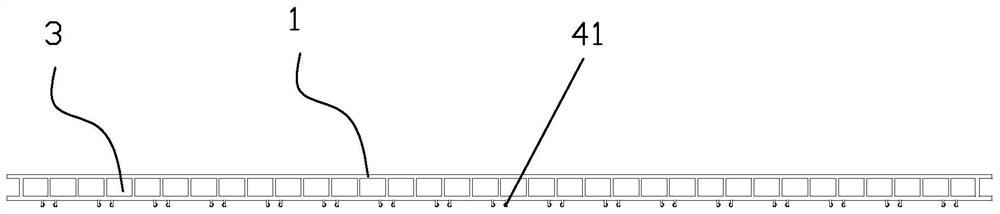

[0052] Wherein, the door panel 1 is provided with a cutting cavity 3 with any width, and the inner surface of the door panel 1 is evenly distributed with a number of mating snap-in structures 4;

[0053] The door side seal assembly 2 includes a card installation part 5 and a door side seal 6; the card installation part 5 is inserted in the door panel width arbitrary cutting cavity 3, and the door side seal 6 is connected with the card installation part 5.

[0054] The door panel 1 is a multi-cavity hollow extruded plate, and the cavities inside the door panel 1 are equal ...

Embodiment 2

[0066] exist Figure 5 , Figure 9 , Figure 11 In the shown embodiment, the technical solution of an assembled door leaf is basically the same as that of Embodiment 1, except that the door leaf panel 1 is a multi-cavity hollow extruded plate, and the cavity inside the door leaf panel 1 The interval size is set, and the shapes of the cavities set by the interval size are different. In this embodiment, square and oval cavities are used for interval setting (see Figure 11 ). In the cutting process, one side is cut at the square cavity, and the other is cut at the oval cavity. Therefore, when using the door leaf side seal assembly 2, one side is connected by a fixed structure, and the other side can be connected at an angle. Adjustable connection.

[0067]The card installation part 5 is connected with the door leaf side seal part 6 in an angle-adjustable manner. The card mounting part 5 includes a universal angle adjustment part 52 and a card mounting part body 53, and the ...

Embodiment 3

[0074] exist Figure 12 In the shown embodiment, the technical solution of an assembled door leaf is basically the same as that of Embodiment 2, the difference is that the door leaf panel 1 is a multi-cavity hollow extruded plate, and the cavity inside the door leaf panel 1 The interval size is set, and the shapes of the cavities set by the interval size are different. In this embodiment, square and oval cavities are used for interval setting (see Figure 11 ). In the cutting process, one side is cut at the square cavity, and the other is cut at the oval cavity. Therefore, when using the door leaf side seal assembly 2, one side is connected by a fixed structure, and the other side can be connected at an angle. Adjustable connection. And the door leaf card assembly 9 adopts such as Figure 8 structure shown. The docking of the door panel 1 is realized through the door card assembly 9 .

[0075] The installation method of the assembled door leaf in the present embodiment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com