Vertical automatic wall tile sticking device for building construction

A kind of building construction and vertical technology, which is applied in the direction of construction and building structure, etc., can solve the problems of low efficiency and slow construction of wall tiles, and achieve the effect of high tile efficiency, saving manpower and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

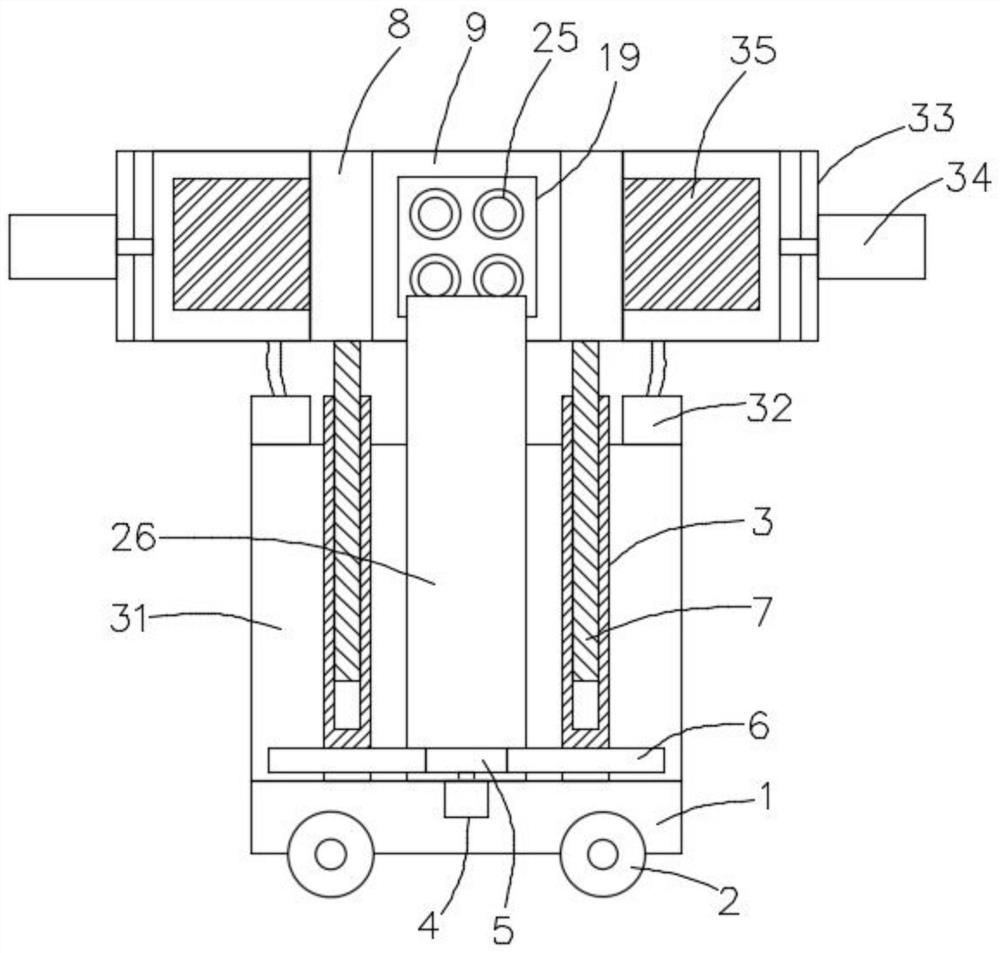

[0025] refer to Figure 1-5 , a vertical automatic wall tile installation for building construction, comprising a mobile platform 1, a plurality of driving wheels 2 are evenly installed on the lower end of the mobile platform 1, and two threaded cylinders 3 are rotatably connected to the upper end of the mobile platform 1, and the threaded cylinder 3 The internal thread is connected with a threaded rod 7, the upper end of the mobile platform 1 is provided with a synchronous driving device, and the upper ends of the two threaded rods 7 are fixedly connected with a lifting plate 8;

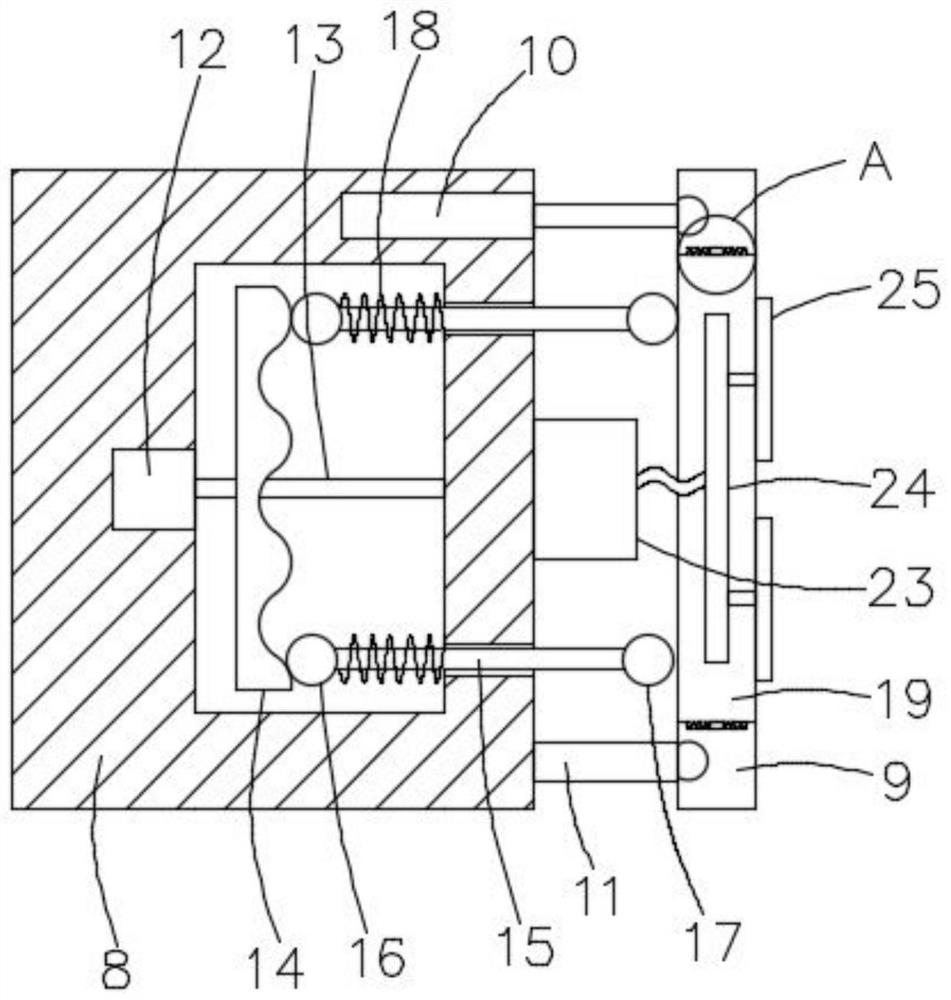

[0026] The front of the lifting plate 8 is provided with a mounting port, the right side of the lifting plate 8 is provided with a mounting plate 9, and the side of the lifting plate 8 near the mounting plate 9 is embedded with a first telescopic cylinder 10, and the telescopic end of the first telescopic cylinder 10 The connecting rod 11 is fixedly connected to the side of the lifting plate 8 close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com