Module node structure connected by adopting clamping device and construction method thereof

A technology of clamping device and node structure, which is applied in the direction of building structure and construction, can solve the problems of difficult field connection, poor connection reliability between modules, and difficult module positioning, so as to solve the problem of positioning difficulty, improve shear resistance, The effect of easy connection operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

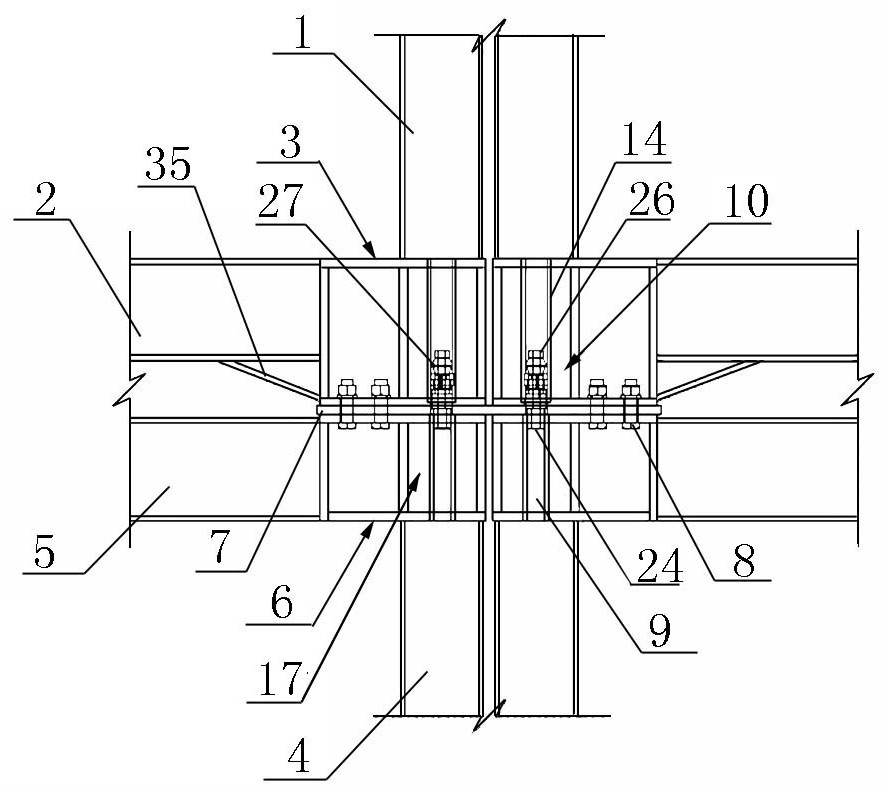

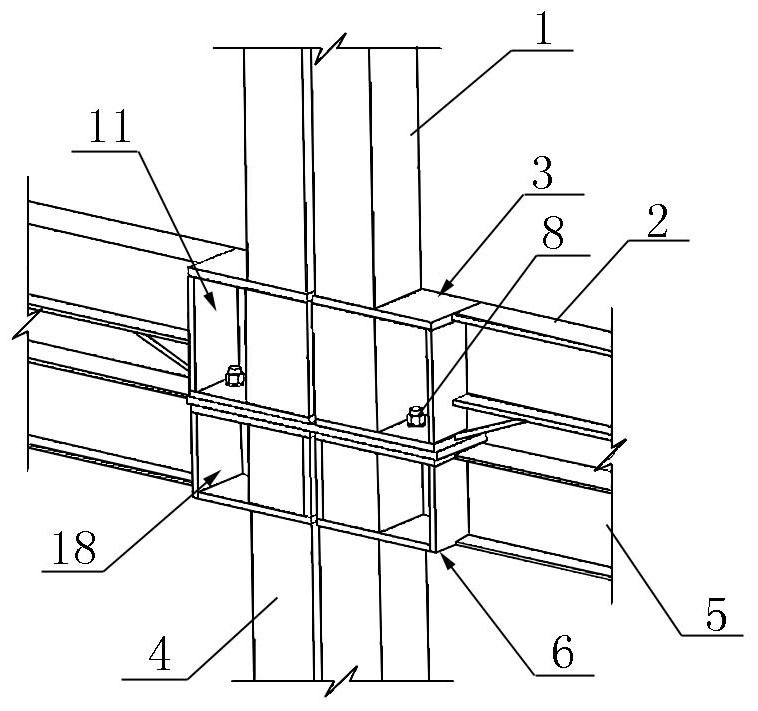

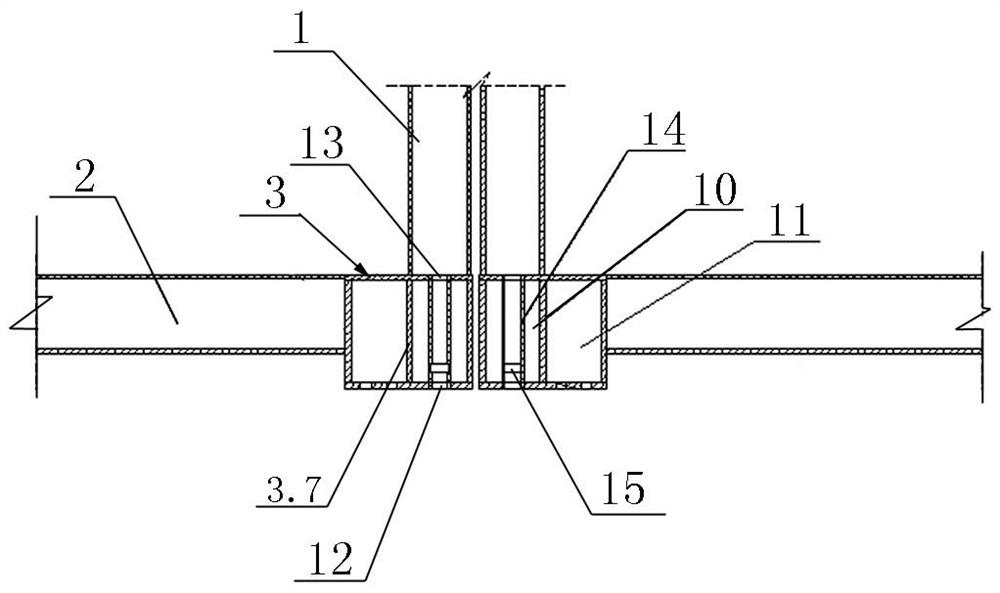

[0047] like Figure 1-11 As shown, this modular node structure connected by a clamping device includes upper column 1, upper bottom beam 2, upper bottom corner piece 3, lower column 4, lower top beam 5 and lower top corner piece 6; it also includes Connecting plate 7, locking device and connecting bolt 8;

[0048] The upper bottom corner piece 3 is a hexahedron structure without an inner surface, including a first top plate 3.1, a first bottom plate 3.2, a first outer transverse plate 3.3, a first outer longitudinal plate 3.4 and a first inner longitudinal plate 3.5; The upper bottom corner piece 3 is connected at the joint between the upper column 1 and the upper bottom beam 2, and the length of the upper bottom corner piece 3 is greater than the length of the horizontal section of the upper column 1, and the width of the upper bottom corner piece 3 is equal to the level of the upper column 1 The width of the cut surface is adapted; inside the upper bottom corner fitting 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com