Water seal odor-resistant cover plate

A cover plate and water seal technology, applied in sewage wells, waterway systems, water supply devices, etc., can solve problems such as harming the health of plant residents, affecting air quality, and dissipation, avoiding personnel fall accidents, protecting the plant environment, and covering solid board effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

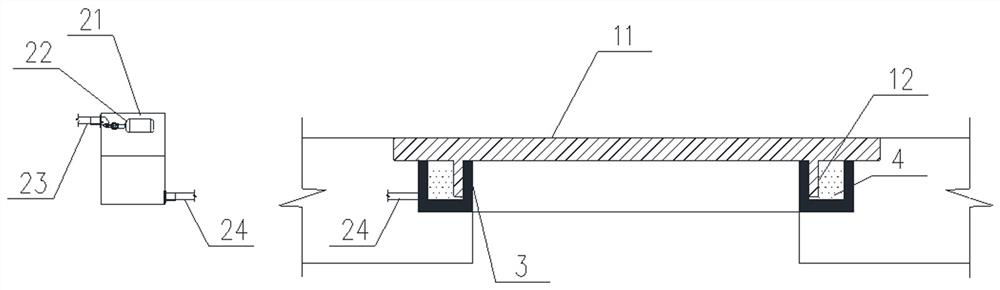

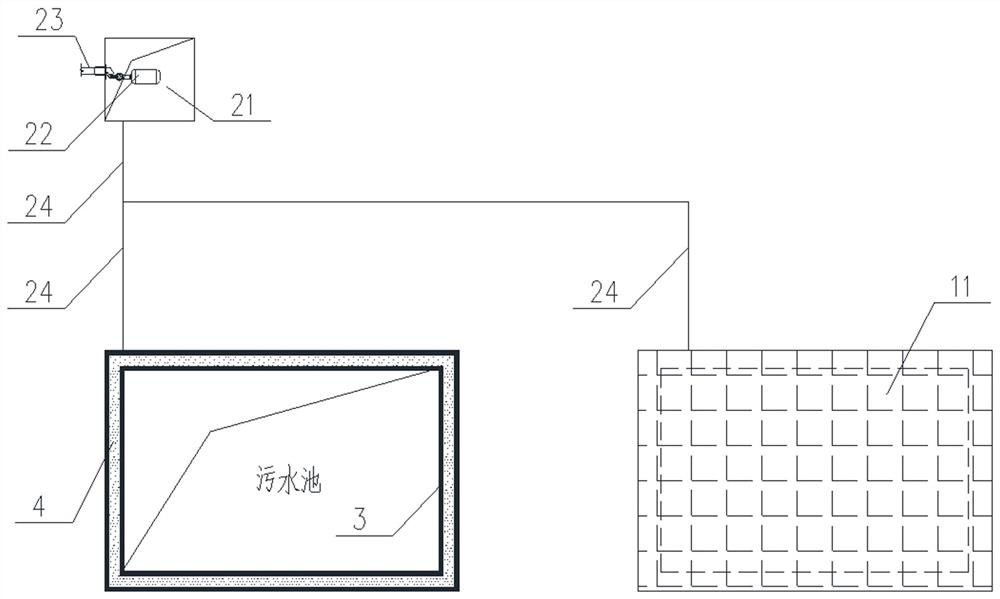

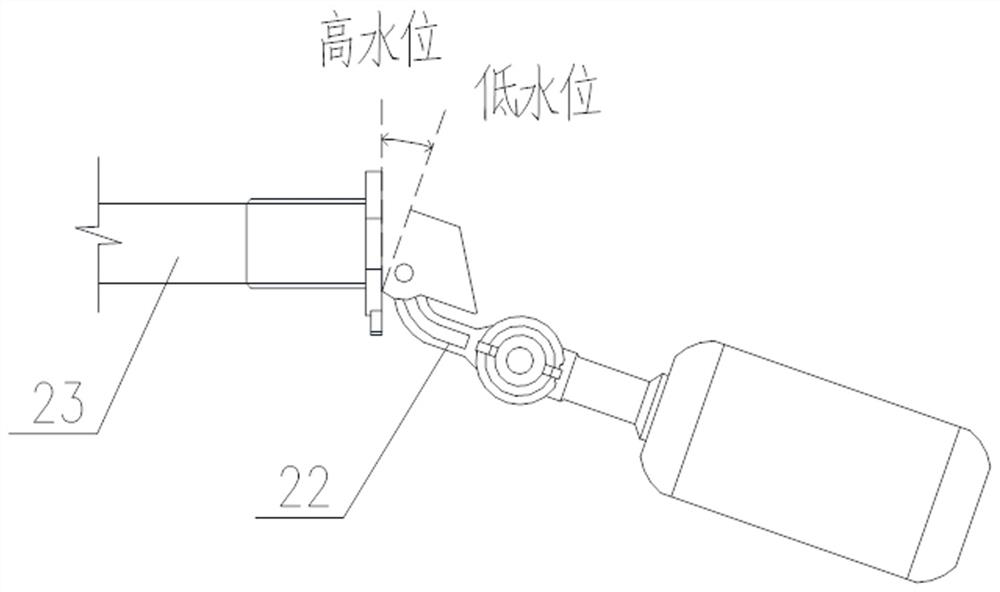

[0021] A water-sealed deodorant cover, such as Figure 1-3 As shown, it includes the pre-embedded frame of the cover plate, the cover plate and the automatic water replenishment device of the water storage tank. The pre-embedded frame of the cover plate is an integrated design, and the material is carbon steel or stainless steel. The pre-embedded frame of the cover plate above the inspection hole is provided with a water retaining wall 3 around the pre-embedded frame of the cover plate, and is filled with water to form a water-sealed groove 4. The water seal groove 4 is connected all around, and the bottom is flush. A cover plate is arranged above the cover plate embedded frame, and the material of the cover plate 11 can be anti-corrosion materials such as glass fiber reinforced plastics and stainless steel. The bottom of the cover plate 11 is provided with a cover plate buckle 12, and the cover plate buckle is located at the edge around the lower side of the cover plate body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com