Single-sided moisture-conducting polyester-acrylic fabric and preparation process thereof

A preparation process, single-sided technology, applied in the field of single-sided moisture-conducting polyester-acrylic fabrics and its preparation, can solve problems such as easy to catch colds, lack of health and safety awareness, etc., and achieve dry and breathable, excellent moisture absorption and quick-drying properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

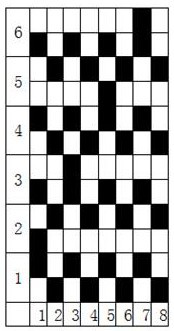

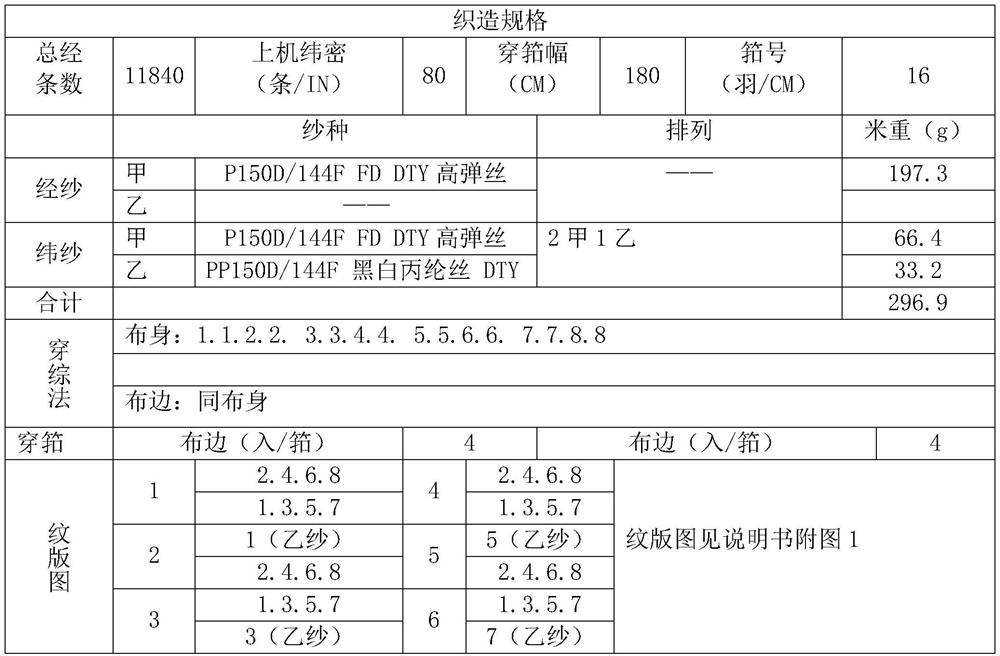

Image

Examples

Embodiment 1

[0035] Step 1, weaving, as mentioned above;

[0036] Step 2, cold-stack desizing: Unroll the polyester-acrylic gray fabric obtained in step 1, and pass through the trough containing the first desizing liquid at 60°C, at a speed of 10 cycles / min, and then fully moisten it by a padding car. wet, then rolled into a roll, and piled up at room temperature for 24 hours; TF-JFC is formulated.

[0037] Put the cold-stacked gray cloth directly into the dye vat for desizing. There is a second desizing liquid in the dyeing vat. The temperature*vehicle speed is 95°C*30M / min; Slurry TF-127, 10g / L scouring emulsifier 120C, 5g / L penetrant TF-JFC is prepared.

[0038] The desizing agent TF-127, the scouring emulsifier 120C, and the penetrating agent TF-JFC are all provided by Zhejiang Transfar Group.

[0039] The method for judging the end point of desizing is to soak the gray cloth after desizing with cationic turquoise blue XF with a mass concentration of 3% based on the weight of the fa...

Embodiment 2

[0045] Step 1, weaving, as mentioned above;

[0046] Step 2, cold-stack desizing: unwind the polyester-acrylic gray fabric obtained in step 1, pass through the trough containing the first desizing liquid at 65°C, rotate at a speed of 12 cycles / min, and then fully moisten it with a paddle car. wet, then rolled into a roll, and stacked at room temperature for 30 hours; the first desizing solution was composed of 65g / L caustic soda, 25g / L desizing agent TF-127, 20g / L scouring emulsifier 120C, 6g / L penetrant TF-JFC is formulated.

[0047] Put the cold-stacked gray cloth directly into the dye vat for desizing. There is a second desizing liquid in the dyeing vat. The temperature*vehicle speed is 92°C*25M / min; Slurry TF-127, 12g / L scouring emulsifier 120C, 4g / L penetrant TF-JFC is prepared.

[0048] The desizing agent TF-127, the scouring emulsifier 120C, and the penetrating agent TF-JFC are all provided by Zhejiang Transfar Group.

[0049] The method for judging the end point of ...

Embodiment 3

[0055] Step 1, weaving, as mentioned above;

[0056] Step 2, cold-stack desizing: unwind the polyester-acrylic gray cloth obtained in step 1, pass through the trough containing the first desizing liquid at 55°C, rotate at a speed of 8 turns / min, and then fully moisten it through a paddle car. wet, then rolled into a roll, and stacked at room temperature for 24 hours; TF-JFC is formulated.

[0057] Put the cold-stacked gray cloth directly into the dye vat for desizing. There is a second desizing liquid in the dyeing vat. The temperature*vehicle speed is 98°C*35M / min; Slurry TF-127, 10g / L scouring emulsifier 120C, 6g / L penetrant TF-JFC is prepared.

[0058] The desizing agent TF-127, the scouring emulsifier 120C, and the penetrating agent TF-JFC are all provided by Zhejiang Transfar Group.

[0059] The method for judging the end point of desizing is to soak the gray cloth after desizing with cationic turquoise blue XF with a mass concentration of 3% based on the weight of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com