Bearing installation detection device

A detection device and bearing technology, applied in mechanical bearing testing, metal processing, metal processing equipment, etc., can solve problems such as bearing damage, affecting work efficiency, and unstable bearing installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] All features disclosed in this specification, or steps in all methods or processes disclosed, can be combined in any way, except for mutually exclusive features and or steps.

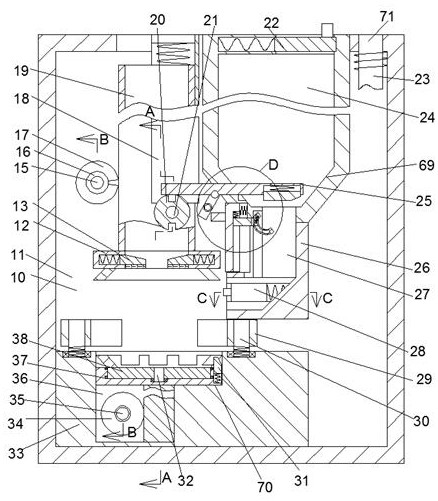

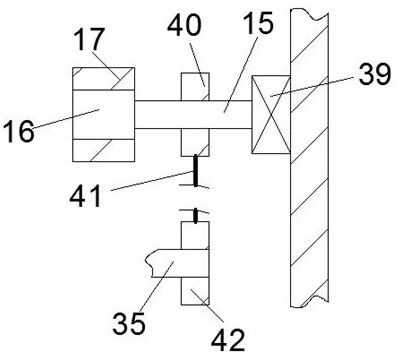

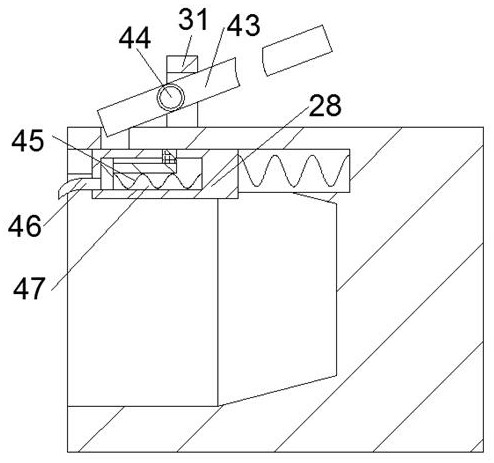

[0019] Combine below Figure 1-5 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent.

[0020] A bearing installation detection device of the device of the present invention includes an installation box 10, and the installation box 10 is provided with an installation cavity 11, and the installation cavity 11 is provided with a discharge valve capable of pushing out the components that need to be combined and maintaining a stable Mechanism 70, the discharge mechanism 70 includes a mounting block 33 fixedly installed on the bottom end wall of the mounting cavity 11, a lifting cavity 36 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com