Assembly for securing the axial position of a sun gear of a planetary gearing stage on a rotor shaft of an electric machine, and use of such an assembly

A planetary gear transmission, sun gear technology, applied in electric components, transmission parts, electrical components, etc., can solve the problems of high cost, inability to open, expensive special fixing rings, etc., to save space, avoid expansion and loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

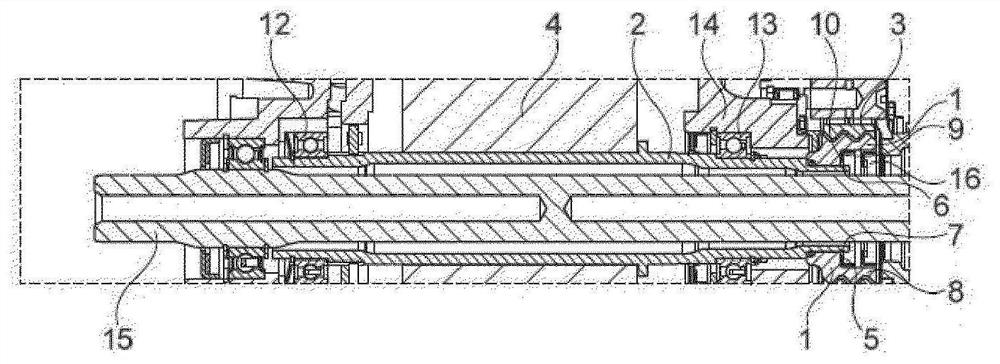

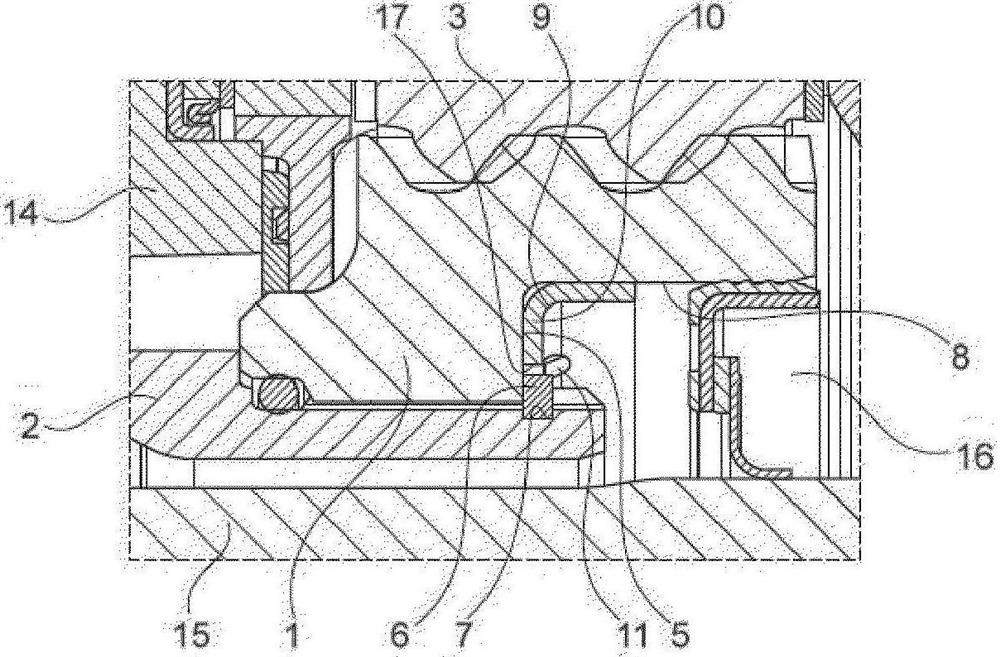

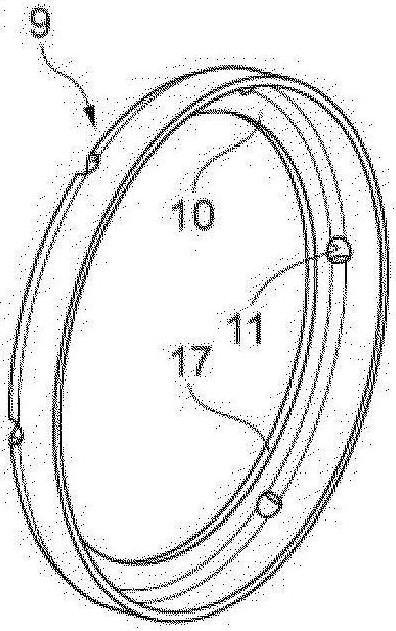

[0021] figure 1 and figure 2 An example of an assembly according to the invention for fixing the axial position of a sun gear 1 of a planetary gear stage on a rotor shaft 2 of an electric machine is shown. A sun gear 1 is non-rotatably assembled on a rotor shaft 2 and meshes with a set of planet gears 3 of a planetary gear stage (not shown) for driving purposes. The rotor shaft 2 carries the coaxially assembled rotor 4 of the electric machine. On the axial side facing away from the rotor, the inner diameter of the sun gear 1 is stepped radially outwards by a radial annular shoulder 5 and is fixed axially on this radial annular shoulder by a fastening ring 6 assembled on the rotor shaft 2 superior. The fixing ring 6 fixes the sun gear 1 axially against its annular shoulder 5 and allows the sun gear to enter a fixing groove 7 on the outer diameter of the rotor shaft 2 for attachment. The annular shoulder 5 delimits an end section 8 of the sun gear 1 , which is stepped radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com