Efficient rail repairing device for rail vehicle

A technology for rail vehicles and rails, which is applied in the field of high-efficiency repairing devices for rails, can solve the problems of easy blockage of discharge ports and inability to realize discharging activities, and achieves the effect of ensuring discharging efficiency, enhancing usability, and ensuring usability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

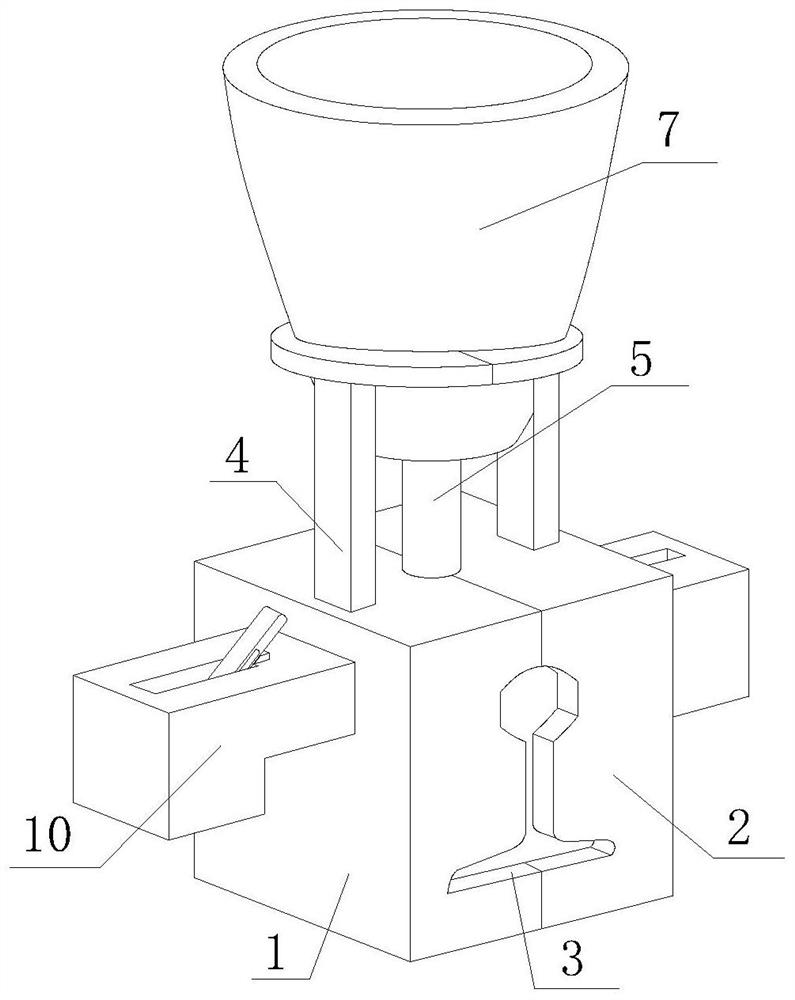

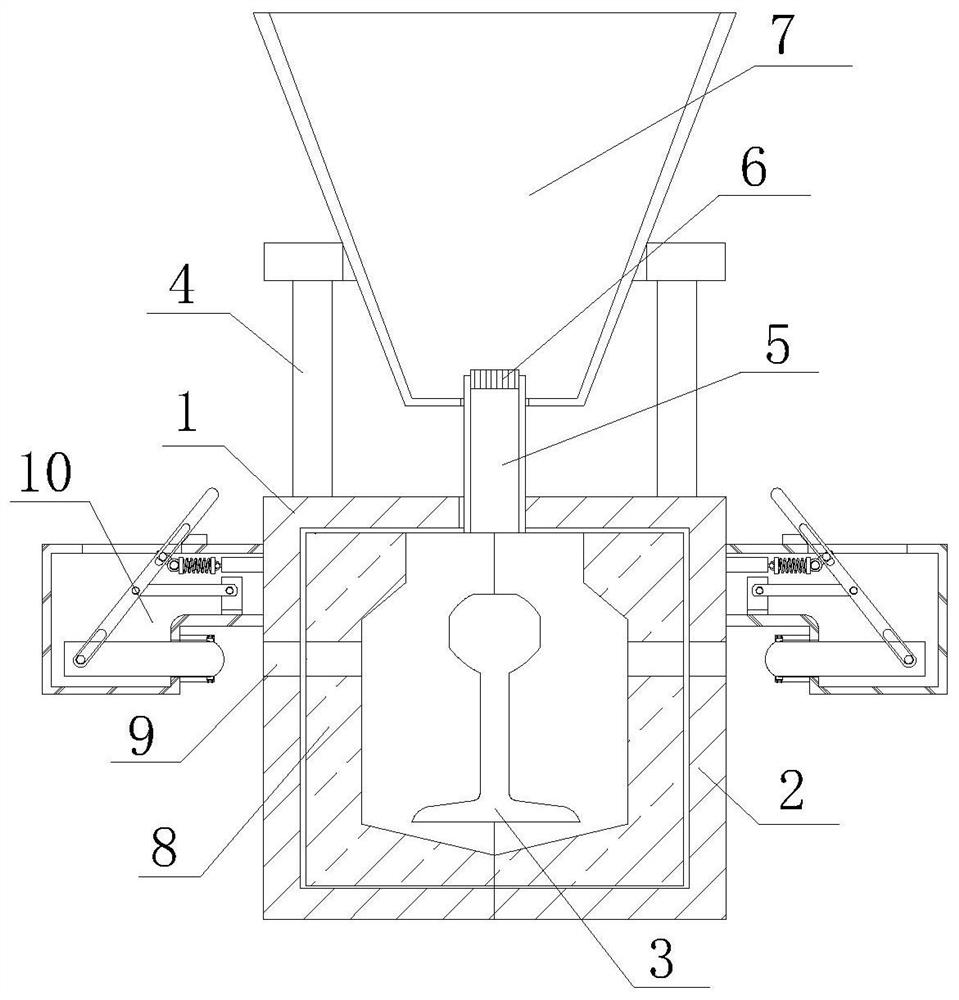

[0030] see figure 1 and figure 2 , the present invention provides a high-efficiency track repair device for rail vehicles through improvement, including a first mold 1 and an anti-blocking device 10, the right side of the first mold 1 is attached to the second mold 2, and the first mold 1 There are mold holes 3 in the middle of the front and rear sides of the second mold 2, the upper ends of the first mold 1 and the second mold 2 are fixedly connected with the receiving frame 4, and the middle part of the upper end of the second mold 2 is fixedly connected with the flow pipe 5, the receiving frame 4. A crucible 7 is installed on the upper end, and the lower end of the crucible 7 is plugged and fixed with the flow pipe 5. The upper end of the flow pipe 5 is provided with a soil cover 6. Both the first mold 1 and the second mold 2 are equipped with a sand mold 8, and the first mold The left side of 1 and the right side of the second mold 2 are both provided with a discharge po...

Embodiment 2

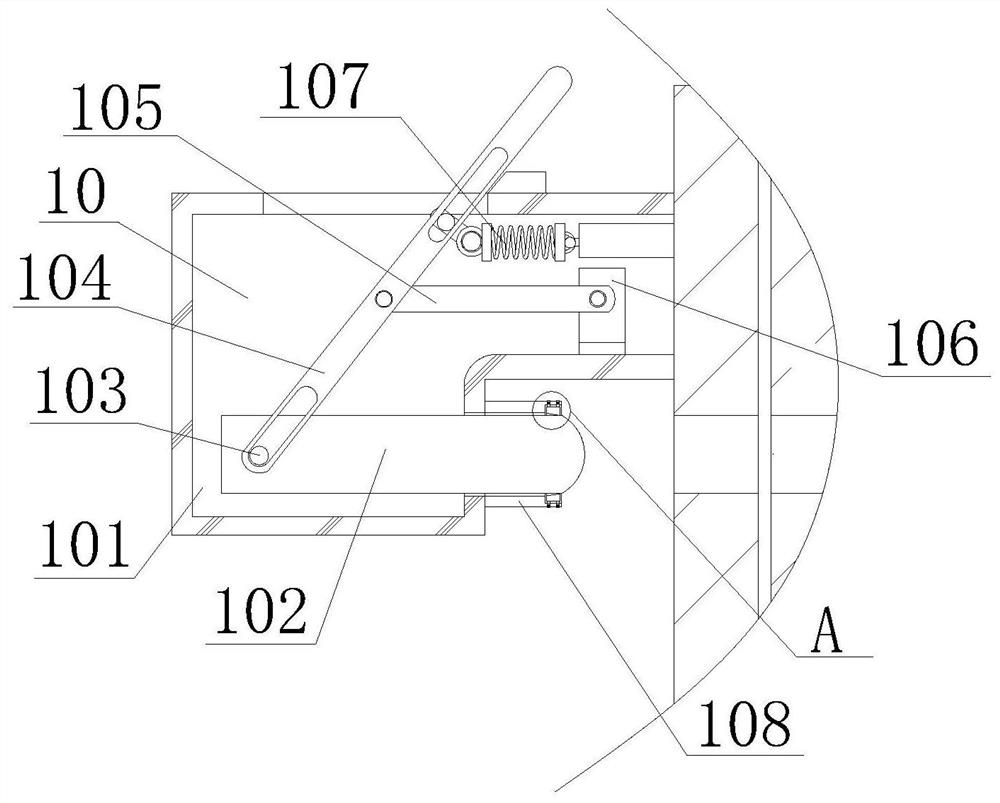

[0035] The present invention provides a high-efficiency track repair device for rail vehicles through improvement. A receiving block is provided on one side of the upper end of the housing 101, and a buffer layer is provided at the contact between the receiving block and the pull rod 104 on the housing 101, so that reset can be avoided. When the speed is too fast and damage occurs, the insertion shaft 1084 and the clip spring 1085 are arranged oppositely along the upper and lower sides of the rejecting ring 1083, and the overall elastic force of the clip spring 1085 is 2.5N, so that the elastic force of the clip spring 1085 ensures that the rejecting ring 1083 and the ejector rod 102 fit.

[0036] The present invention provides a kind of high-efficiency track repair device for rail vehicle through improvement, and its working principle is as follows;

[0037] First, first put the first mold 1 and the second mold 2 into the sand mold 8, and then place the first mold 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com