Yarn suction device of draw texturing machine

A technology of silk aspirator and texturing machine, which is applied in the direction of conveying filamentous materials, textiles, papermaking, thin material processing, etc. It can solve the problems of low efficiency and high labor intensity of workers, so as to reduce labor intensity and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

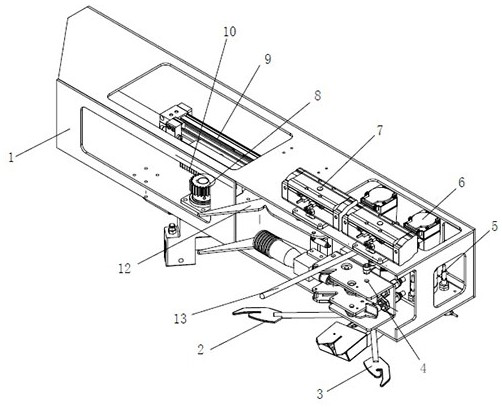

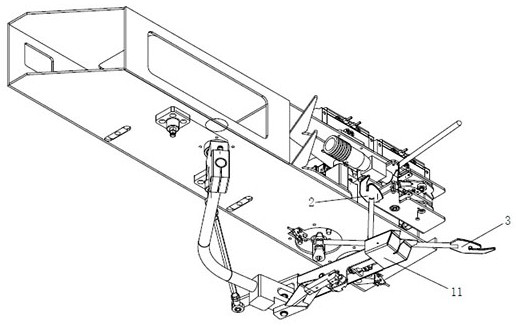

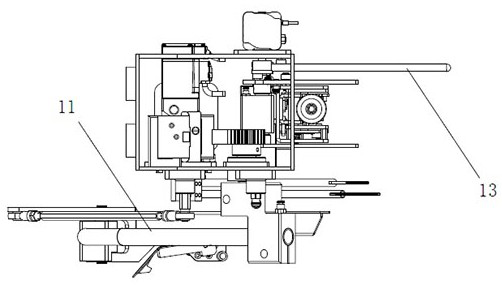

[0020] Such as Figure 1 to Figure 7 As shown, a doffing wire suction and wire feeding device of a texturing machine in this embodiment includes a main body 1, a right wire drawing arm 2, a left wire drawing arm 3, a wire suction device 4, a planetary reducer 5, a servo motor 6, and a gear 8. A rodless cylinder 9 , a rack 10 and a wire feeding mechanism 11 , the rodless cylinder 9 is arranged in the body 1 , and the rodless cylinder 9 is connected to the rack 10 . The gear 8 is meshed with the rack 10, the gear 8 is connected to the wire feeding mechanism 11, the right wire driving arm 2 and the left wire driving arm 3 are respectively connected to the servo motor 6 through the planetary reducer 5, and the servo motor is arranged on In subject 1. The wire suction device 4 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com