Rubber tube for stethoscope

A technology for stethoscopes and rubber hoses, applied in stethoscopes and other directions, can solve the problems of loud touch noise, easy breeding of bacteria, and sticky hoses, etc., and achieve the effect of reduced touch noise and excellent performance for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

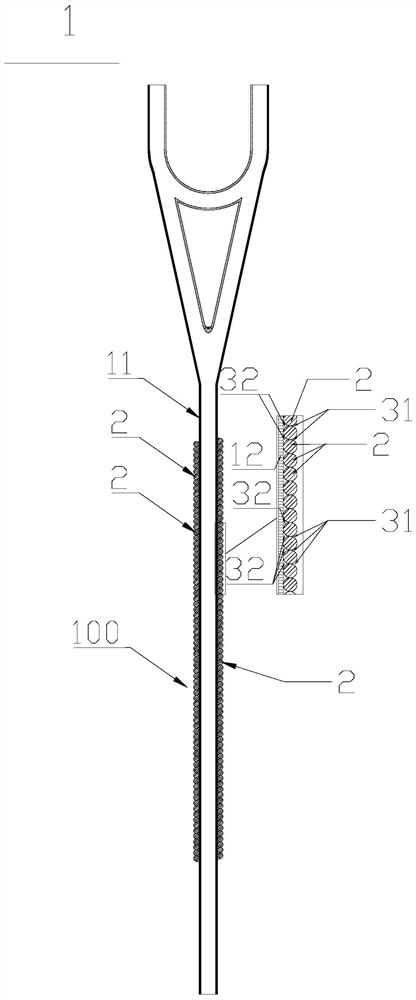

[0099] Embodiment 1: as figure 1 , figure 2 shown

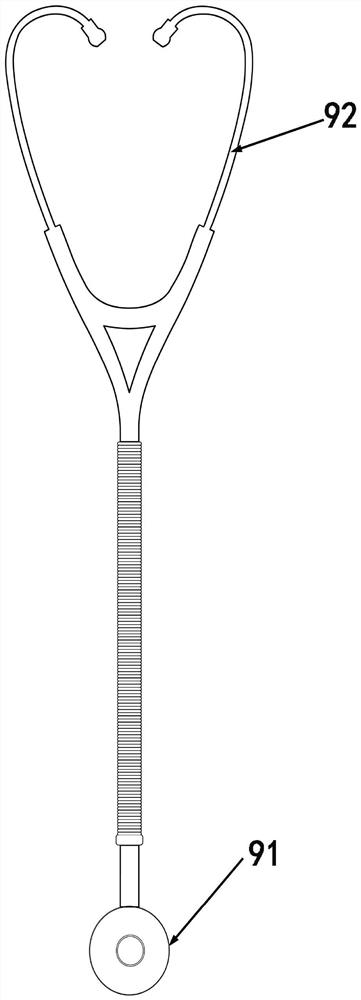

[0100] A stethoscope includes an ear hook 92, a rubber tube 1 and a listening head 91.

[0101] The rubber tube 1 for a stethoscope is provided with a covering 100 on the outer wall 11 of the rubber tube.

[0102] The covering 100 is formed by winding the wire 2 around the outer wall 11 of the rubber hose 1 along the axial direction of the rubber hose 1 .

[0103] The lines 2 are arranged next to each other on the outer wall 11 of the hose. A hole 32 is formed immediately before the line 2 and the outer wall 11 of the hose 1 . A wedge 31 opening outwards is formed between adjacent lines 2 .

Embodiment 2

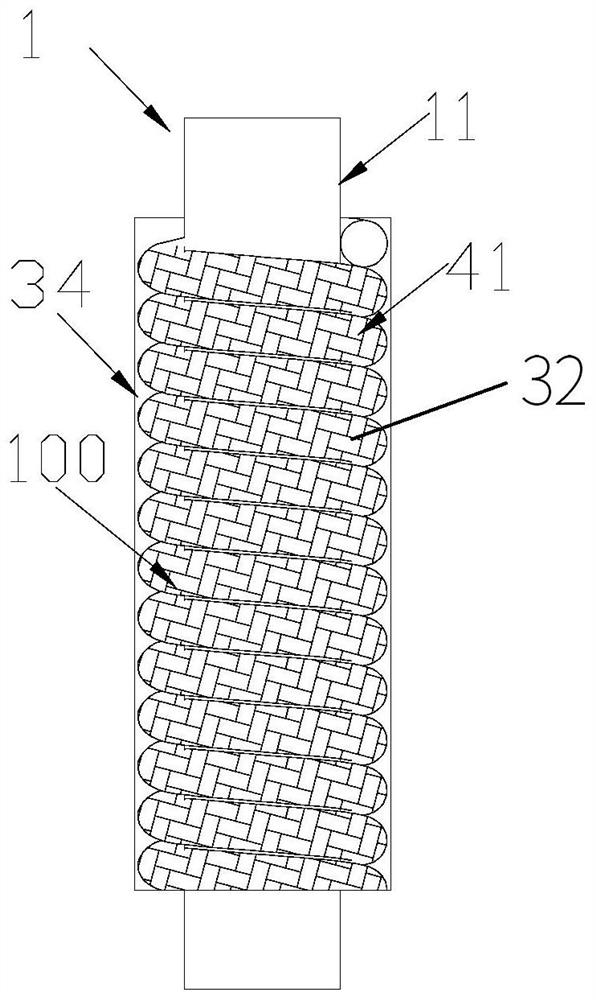

[0104] Embodiment 2: as image 3 , Figure 4 shown

[0105] The rubber tube 1 for a stethoscope is provided with a covering 100 on the outer wall 11 of the rubber tube.

[0106] The cover 100 is formed by wrapping the wire 2 around the outer wall 11 of the rubber hose 1 along the axial direction of the rubber hose 1 to form a wire layer 41 .

[0107] The lines 2 are arranged next to each other on the outer wall 11 of the hose.

[0108] The thread 2 has a loose tissue structure with several pores 32 , and a coating layer 34 is provided on the outer surface of the thread 2 .

Embodiment 3

[0109] Embodiment 3: as Figure 5 , Figure 6 shown

[0110] The rubber tube 1 for a stethoscope is provided with a covering 100 on the outer wall 11 of the rubber tube.

[0111] The cover 100 is formed by wrapping the wire 2 around the outer wall 11 of the rubber hose 1 along the axial direction of the rubber hose 1 to form a wire layer 41 .

[0112] The lines 2 are arranged next to each other on the outer wall 11 of the hose.

[0113] The thread 2 has a loose tissue structure with several pores 32 , and a coating layer 34 is provided on the outer surface of the thread 2 .

[0114] The end of the covering 100 and the head of the thread 2 are fixed by the fixing sleeve 4, which can prevent the covering 100 from spreading and improve the aesthetics of the end of the covering 100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com