Quick plugging method for fuel pipeline

A technology for pipelines and fuel oil, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of inability to achieve permanent sealing, long time, and difficult cleaning of sludge, and shorten the scope of pipeline flushing. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

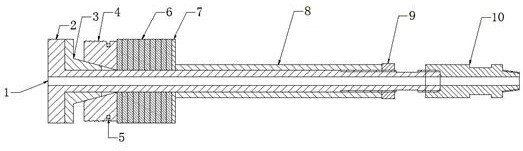

[0037] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0038] Several isolation valves are arranged on the fuel pipeline, thereby dividing the whole fuel pipeline into multiple segments, and a drain valve and a water injection valve are also installed on each segment.

[0039] The fast plugging method of the fuel pipeline of the present invention is realized through the following steps:

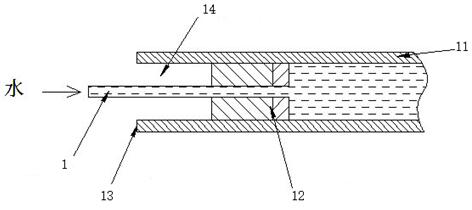

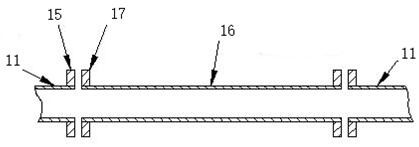

[0040] S1 Pretreatment: First, close the two isolation valves at the front and back of the section 11 where the leaking pipe section is located, and then open the drain valve on the section to drain the oil in the pipeline of this section 11 .

[0041] S2 Pipe section cutting: Open the water injection valve set on the section 11, and inject water into the pipeline of section 11. This part of water injection is used to cool down, avoiding the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com