Timed cleaning equipment for mechanical parts on basis of remote control

A technology for mechanical parts and regular cleaning, applied in the field of mechanical equipment, which can solve problems such as single function, residual debris, and no automated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

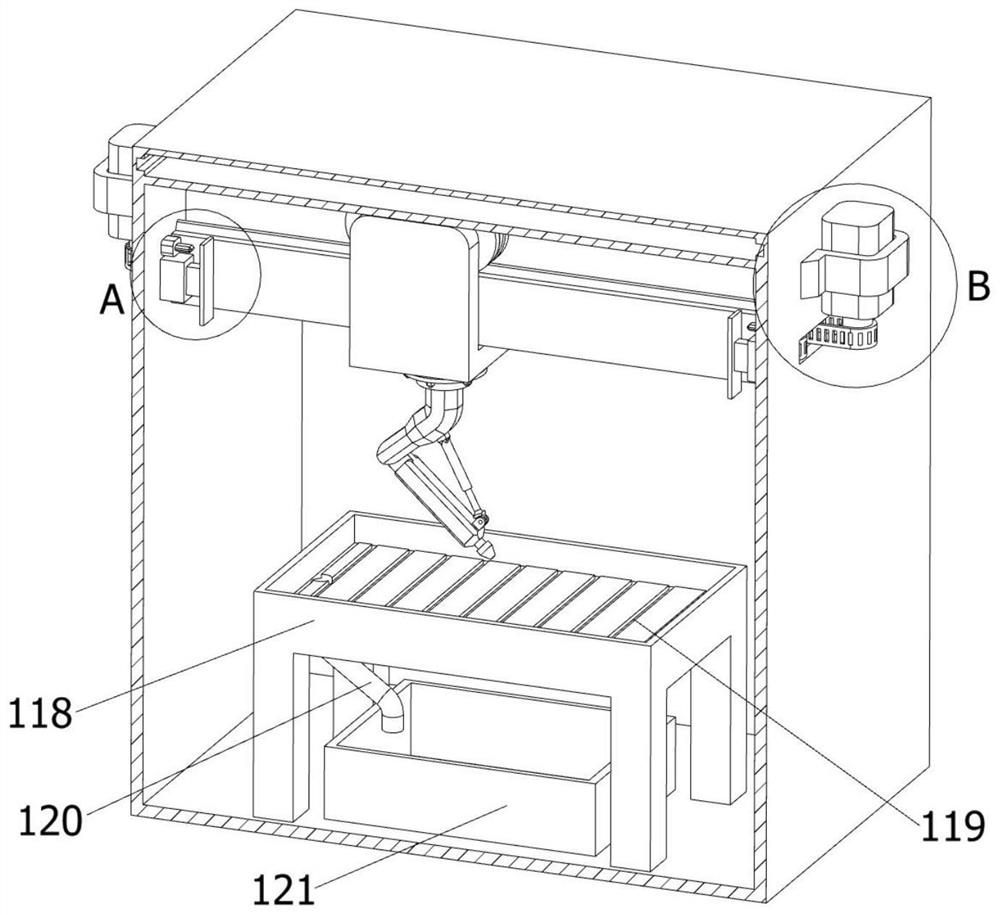

[0030] as attached figure 1 to attach Figure 6 Shown:

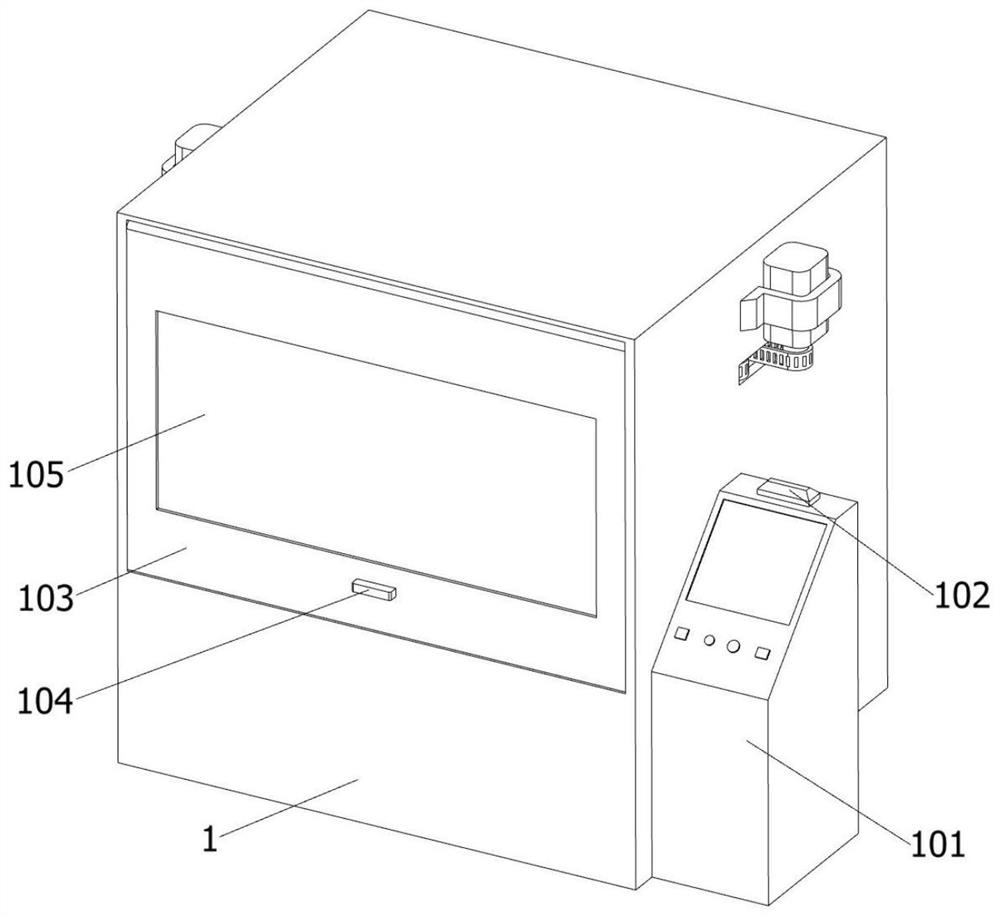

[0031] The present invention provides a timing cleaning device for mechanical parts based on remote control, which includes a box body 1; Receiver 102 ; a sliding platform 2 is slidably connected in the box body 1 .

[0032] Reference as figure 1 and Figure 5 , the box body 1 also includes a box door 103, a handle 104, an observation window 105, a chute 106 and a guide slot A107, a chute 106 is provided at the top of the box body 1, and a guide slot A107 is respectively opened on the left and right sides of the chute 106 , and the top of the door 103 is slidably connected in the guide groove A107, the door 103 is provided with a handle 104, and the door 103 is also provided with an observation window 105, thereby realizing the effect of sliding the door 103 away.

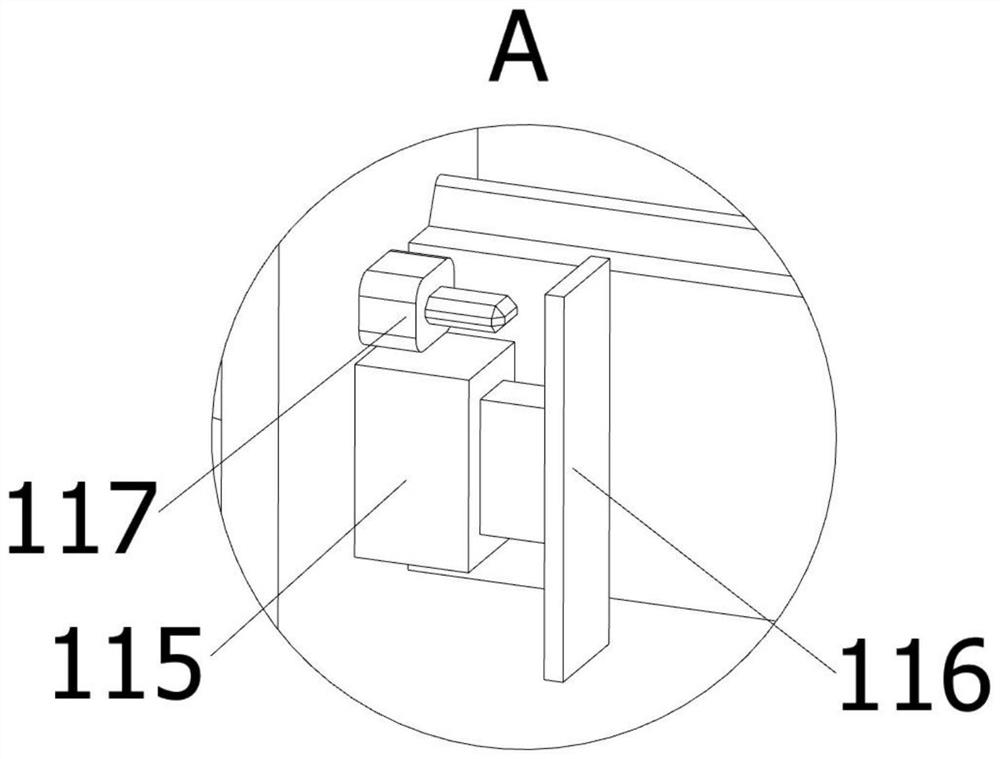

[0033] Reference as Figure 5 and Figure 6 , the box body 1 also includes a beam 108 and a guide rail 109, a beam 108 is welded on the top of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com