A Distributed Annular Gap Ejector Device

An ejector and distributed technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problems of long mixing section, low ejection efficiency, and poor uniformity of mixed fluid, so as to reduce installation space requirements and improve ejection efficiency. The effect of high efficiency and ejection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

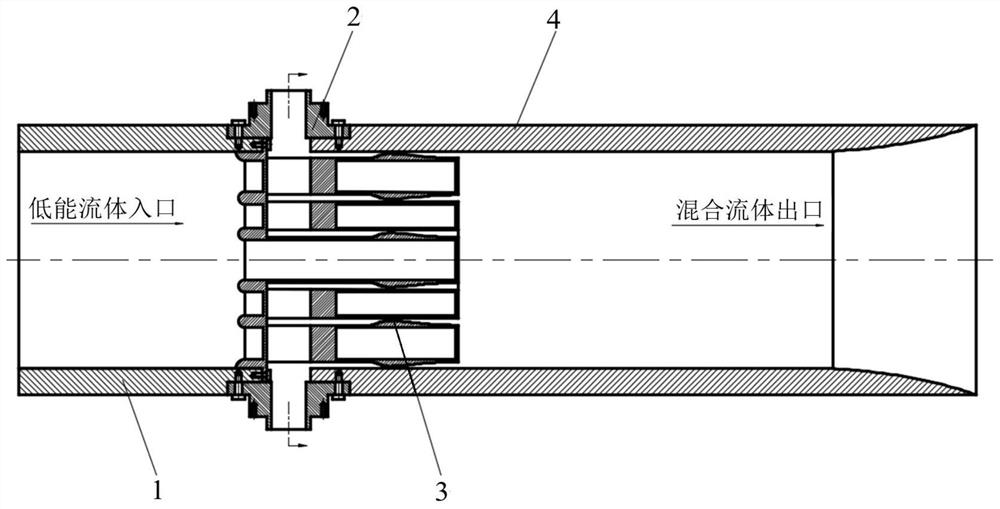

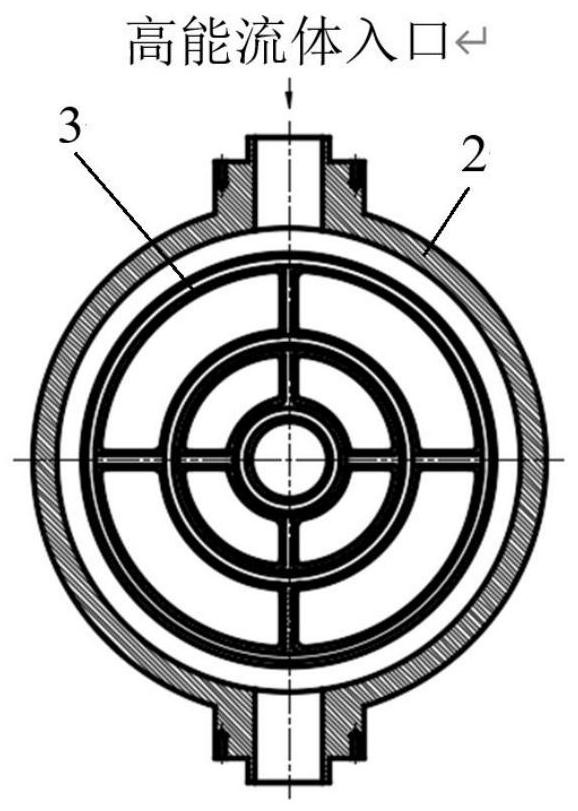

[0037] The number of nozzle unit bodies in this embodiment is 3, each nozzle unit body is provided with an axisymmetric binary semi-nozzle pipe, and each nozzle unit body is connected from the inner ring to the outer ring by 4 centrally symmetrical nozzles. The hollow type reinforcing rib is connected and supported; the annular cavity communicated with each nozzle unit body is also arranged in the binary annular slit ejector 3, and the high-energy fluid enters the annular cavity from the through hole of the high-energy fluid inlet section 2 and flows from the The outlet of the nozzle unit body sprays out.

[0038] The numerical simulation results show that, compared with the traditional annular seam ejector, the distributed annular seam ejector device of this embodiment requires less space under the premise of achieving the same ejection effect. Specifically, the diameter of the pipe section can be It can be reduced by more than 30%, and the length of the pipe section can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com