An automatic hangar for drones

An unmanned aerial vehicle, automatic technology, applied in the field of unmanned aerial vehicles, can solve problems such as error-prone efficiency, achieve the effect of automatic take-off and avoid a large number of manual participation in the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

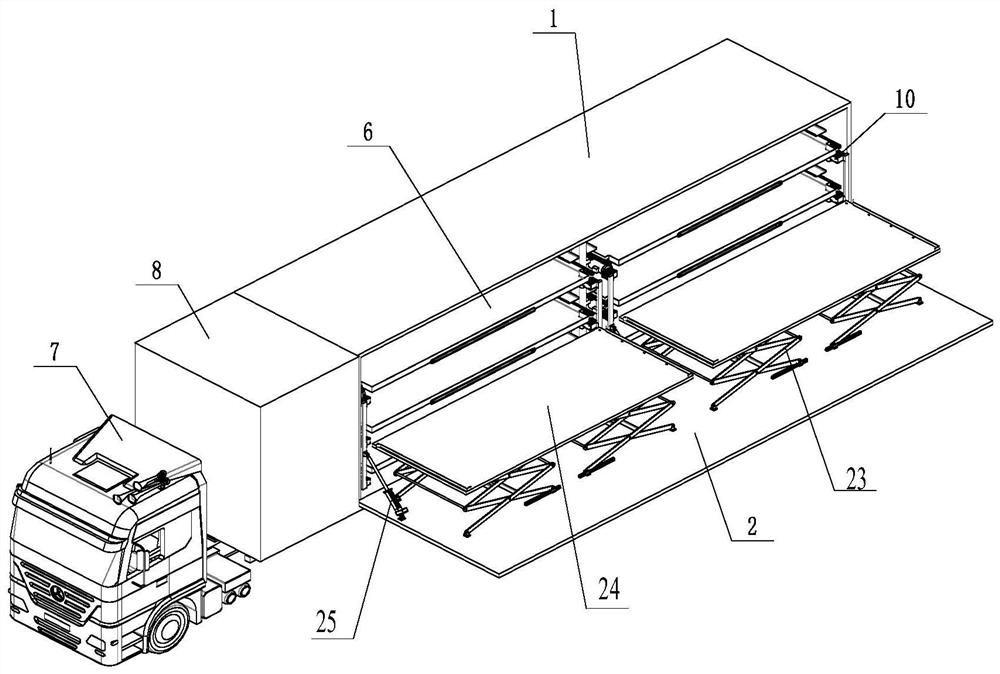

[0065] Please refer to figure 1 and Figure 4 , an automatic hangar for unmanned aerial vehicles, the automatic hangar for unmanned aerial vehicles comprises: a movable carrier 7, a storage body 1, a storage door 2, several storage areas for unmanned aerial vehicles, several locking devices, several transplanting jacks Mechanism, wireless charging system, control system and power supply system, wherein, a number of unmanned aerial vehicle storage areas are arranged in the warehouse, and each unmanned aerial vehicle storage area corresponds to an unmanned aerial vehicle storage unit 6, and each unmanned aerial vehicle storage area Each is equipped with a locking device for fixing the storage unit of the UAV; the warehouse body is provided with a warehouse door, and the warehouse door is provided with a transplanting and lifting mechanism, which is used to store the UAV. The unit is taken out from the corresponding UAV storage area and the UAV storage unit is stored in the corr...

Embodiment 2

[0092] Such as Figure 5 and Figure 6 As shown in the transplanting jacking mechanism, the inner wall of the door panel 22 is provided with a jacking mechanism 23, and the end of the jacking mechanism 23 away from the door panel 22 is connected to the lifting platform 24, and the lifting platform 24 is provided with a transfer mechanism; the lifting platform 24 is used to carry the unmanned aerial vehicle ; The jacking mechanism 23 is used to make the landing platform 24 close to and away from the door panel 22 ; The bottom edge of the door panel 22 is used to be hinged with the side of the hangar; The upper surface of the lifting platform 3-24 is parallel to the inner side wall of the door panel 22; the lifting platform 24 and the jacking mechanism 23 together form a scissor lifting platform.

Embodiment 3

[0094] Such as Figure 5 to Figure 10The transplanting jacking mechanism shown, on the basis of the second embodiment, this embodiment optimizes the design of the transfer mechanism, specifically: the transfer mechanism includes a conveyor belt 26 capable of reciprocating movement, and the conveyor belt 26 is fixedly connected to the plectrum 27 ; Also includes a first driving device 28 for driving the conveyor belt 26 . The first driving device 28 is a motor, and the conveyor belt 26 is a chain or a belt; the conveyor belt 26 rotates around the driving wheel 29 and the driven wheel 30, and the first driving device 28 drives the driving wheel 29 to rotate. It also includes a third slide rail 31 fixed on the landing platform 24 , one end of the third slide rail 31 protrudes out of the landing platform 24 , and the end extends toward the interior of the storage body when the storage door is opened. Also includes a mounting part 32 that is slidably connected on the third slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com