Airplane model airship suction structure

A model and airship technology, applied in the field of occupancy structure of aeronautical model airships, can solve problems such as difficulty in ensuring safety, ground collision, and damage

Inactive Publication Date: 2017-09-29

王贺

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The older mooring method for take-off and landing of aviation model airships is to pull the mooring rope of aviation model airships, which is not easy to ensure safety in case of strong winds

Some are tied to buildings, large tree stumps or vehicle frames. Aircraft model airships swing with the wind like a weathervane, and are easy to collide with the ground and cause damage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

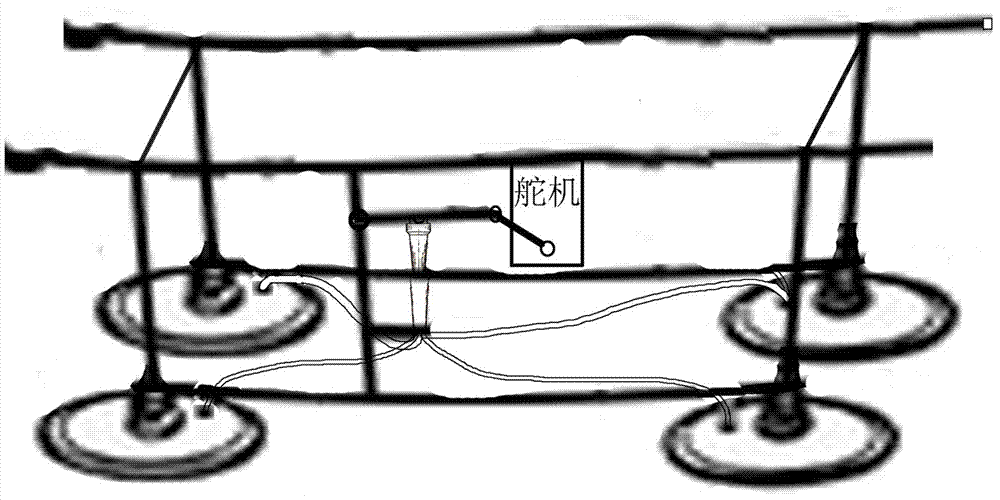

[0005] according to figure 1 , figure 2 It can be installed as shown, and it can be used after installing other common equipment such as power.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The air model airship occlusion structure is a kind of air model airship occlusion structure controlled by a remote controller for adsorption and detachment. Install four suction anchors at the bottom of the aircraft model airship, install the suction anchors directly on the landing gear (or install a special telescopic bracket or hose), and directly adsorb the aircraft model airship on the ground platform (or wall). The suction anchor is connected to the tapered rubber switch through the thin tube, and the rubber switch is pulled by the steering gear controlled by the remote controller, and the closure and opening of the suction anchor are changed by the principle of atmospheric pressure to realize landing, parking and take-off. The invention is not easily damaged, safe and reliable, strong in wind resistance, flexible in maneuvering and easy to operate. The number and location of suction anchors can be increased according to specific conditions.

Description

technical field [0001] The present invention is a kind of occlusion structure for aircraft model airship that can be parked, in particular a more convenient and fixed aircraft model airship occlusion structure, in particular a occlusion structure for parking and mooring aircraft model airship controlled by a remote controller. Background technique [0002] Aircraft model airships are blown away and destroyed by strong winds if they are not anchored on the ground. The older aircraft model airship take-off and landing mooring method is to pull the mooring rope of the aircraft model airship, which is not easy to ensure safety if it meets high winds. Some are tied to buildings, large tree stumps or vehicle frames, and the model aircraft airship swings with the wind like a weathervane, and it is easy to collide with the ground and cause damage. When the aircraft model airship stays in the field, it is impossible to have perfect mooring equipment, and it is often used in remote p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A63H27/18A63H27/32

CPCA63H27/02

Inventor 王贺王怡颖

Owner 王贺

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com