Decorative sheet structure and construction method thereof

A decorative panel and back panel technology, applied in the field of building decoration, can solve the problem that the decorative panel cannot be disassembled, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

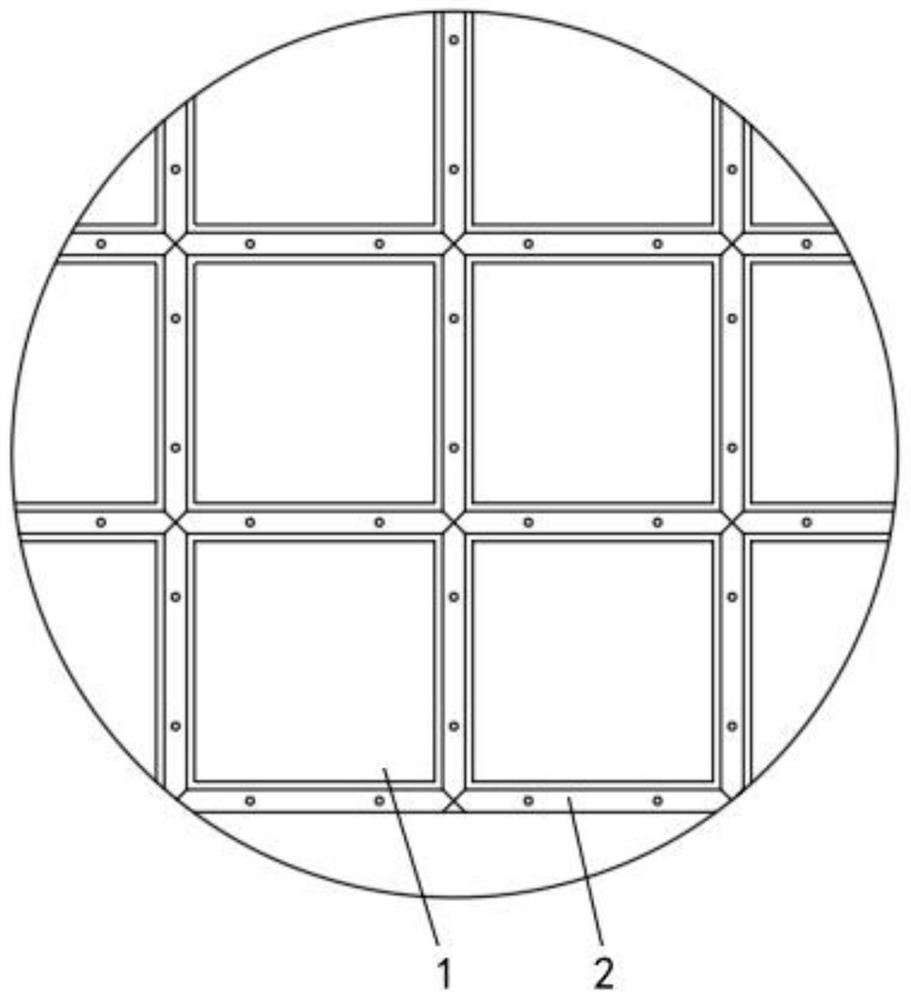

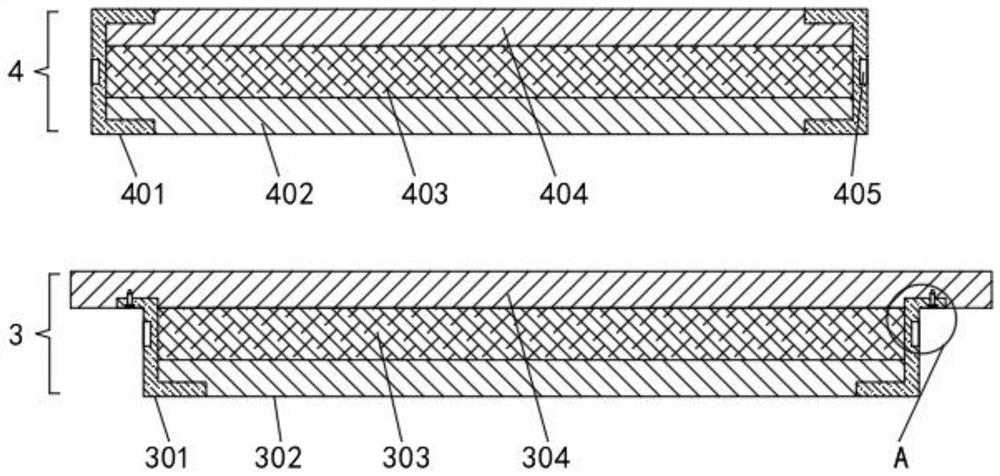

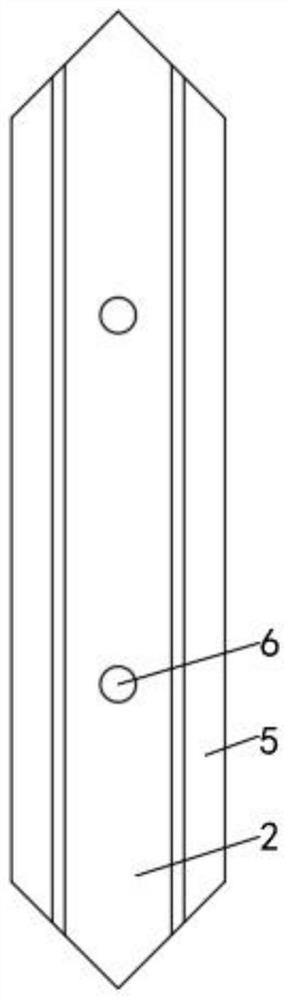

[0032] like Figure 1-7 As shown, the embodiment of the present invention provides a decorative board structure, including a single decorative board 1, a fixing rod 2 is arranged on the outside of the single decorative board 1, and the single decorative board 1 is divided into a first decorative board 3 and a second decorative board. Plate 4, rubber pads 5 are provided on both sides of the front of the fixed rod 2, round holes 6 are arranged symmetrically in the middle of the fixed rod 2, the number of round holes 6 is two, and the middle part of the fixed rod 2 is below the round hole 6 Both are provided with a square hole 8, and the inside of the square hole 8 is provided with a sleeve 10, the sleeve 10 penetrates upwards to the inside of the round hole 6, the upper end of the sleeve 10 is set inside a hexagon socket 12, and the side wall of the sleeve 10 And in the inside of the square hole 8 is fixedly connected with a clamping rod 11, the inside of the sleeve 10 is penetr...

Embodiment 2

[0035] An embodiment of the present invention provides a construction method for a decorative panel structure, including the following:

[0036] 1. Fixing of the fixing rod 2: Drill holes in the building wall, then place the nuts matching the first bolt 7 in the holes for fixing, and fix the fixing rod 2 on the building through the threaded connection between the first bolt 7 and the nut. On the object, turn the first bolt 7 to adjust the verticality of the fixed rod 2, and finally insert the cross connector 15 in the third slot 16 at one end of the fixed rod 2, and then install the other three fixed rods 2;

[0037] 2. Installation of the decorative board monomer 1: place the decorative board monomer 1 in the frame formed by the fixed rod 2, take the first decorative board 3 as an example, the first fixed side 301 is in contact with the rubber pad 5, and then from the circle Insert the hexagon socket tool into the hole 6, snap into the socket 12, turn the sleeve 10 so that th...

Embodiment 3

[0039] A construction method for a decorative panel structure, comprising the following:

[0040] 1. Fixing of the fixing rod 2: Drill holes in the building wall, then place the nuts matching the first bolt 7 in the holes for fixing, and fix the fixing rod 2 on the building through the threaded connection between the first bolt 7 and the nut. On the object, turn the first bolt 7 to adjust the verticality of the fixed rod 2, and finally insert the cross connector 15 in the third slot 16 at one end of the fixed rod 2, and then install the other three fixed rods 2;

[0041] 2. Installation of the decorative board monomer 1: place the decorative board monomer 1 in the frame formed by the fixed rod 2, take the second decorative board 4 as an example, the second fixed side 401 is in contact with the rubber pad 5, and then from the circle Insert the hexagon socket tool into the hole 6, snap into the socket socket 12, turn the sleeve 10 so that the clamp rod 11 provided on the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com