Hollow glass pressing and glue-sealing equipment set

An equipment group and glass technology, which is applied in the field of hollow glass pressing and sealing equipment, can solve the problems of moving the frame after separation, reducing production efficiency, and single sealing color, so as to ensure position stability, improve lamination quality, The smooth effect of the moving frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] The embodiment of the present application discloses a hollow glass pressing and sealing equipment group, which adopts the following technical scheme:

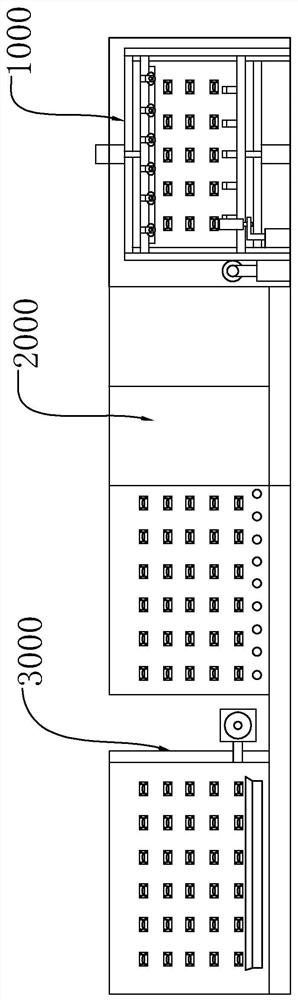

[0096] A hollow glass pressing and sealing equipment group, refer to figure 1 , sequentially including a lamination device 1000, a thermocompression device 2000 and a sealing device 3000;

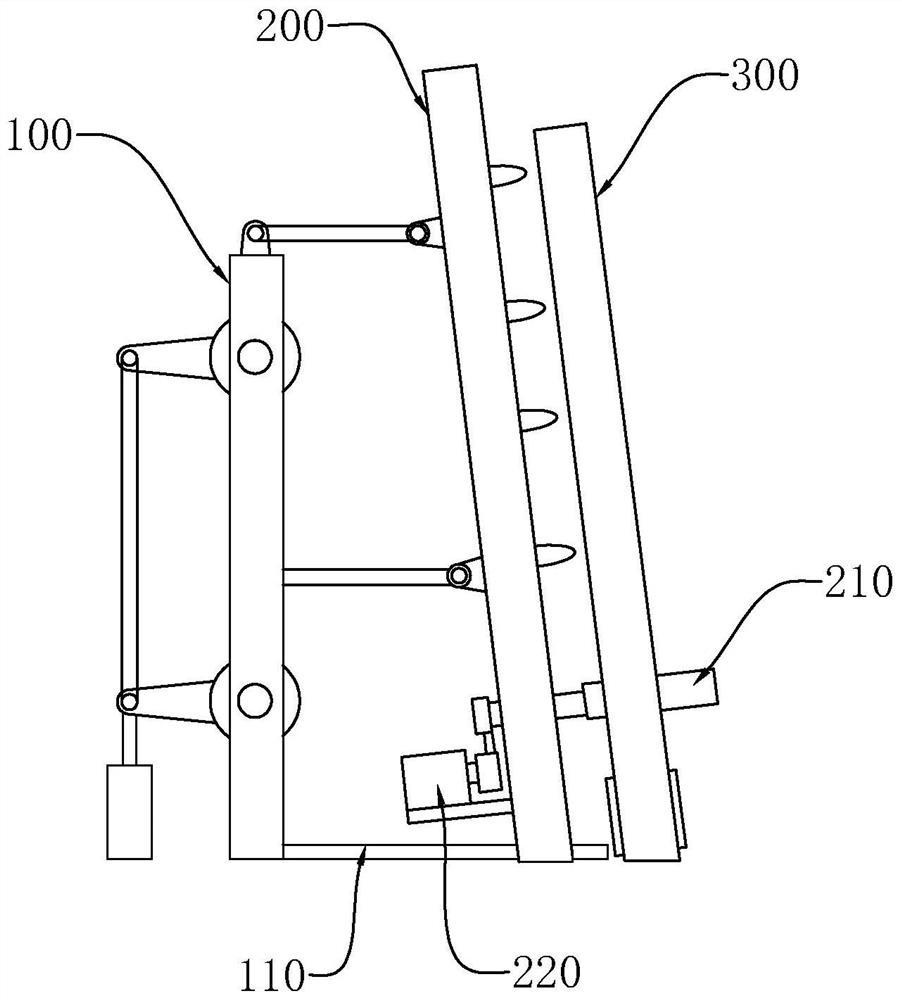

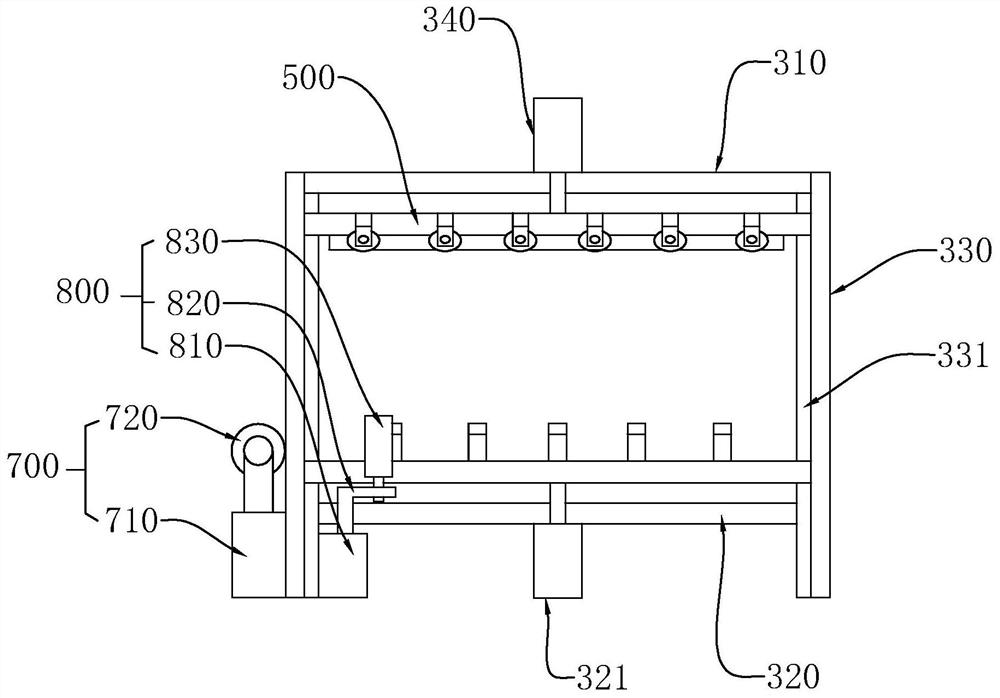

[0097] refer to figure 2 and image 3 , wherein, in the present embodiment, the stacking device 1000 includes a fixed frame 100, a movable frame 200 and an isolation frame 300 arranged in sequence, the fixed frame 100 is provided with an elastic drive mechanism 400 for driving the movable frame 200 to move, the fixed frame 100 and the The mobile frame 200 is connected by an elastic drive mechanism 400; the bottom end of the fixed frame 100 is provided with a first slide rail 110, and the lower end of the mobile frame 200 is clamped on the slide rail; the spacer 300 is arranged on the outside of the mobile frame 200 to isolate The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com