Plastic plate multi-roller embossing machine

A plastic sheet and roll pressing technology, which is applied in the field of plastic sheet multi-roll embossing machines, can solve the problems of time-consuming, labor-intensive, low production efficiency, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

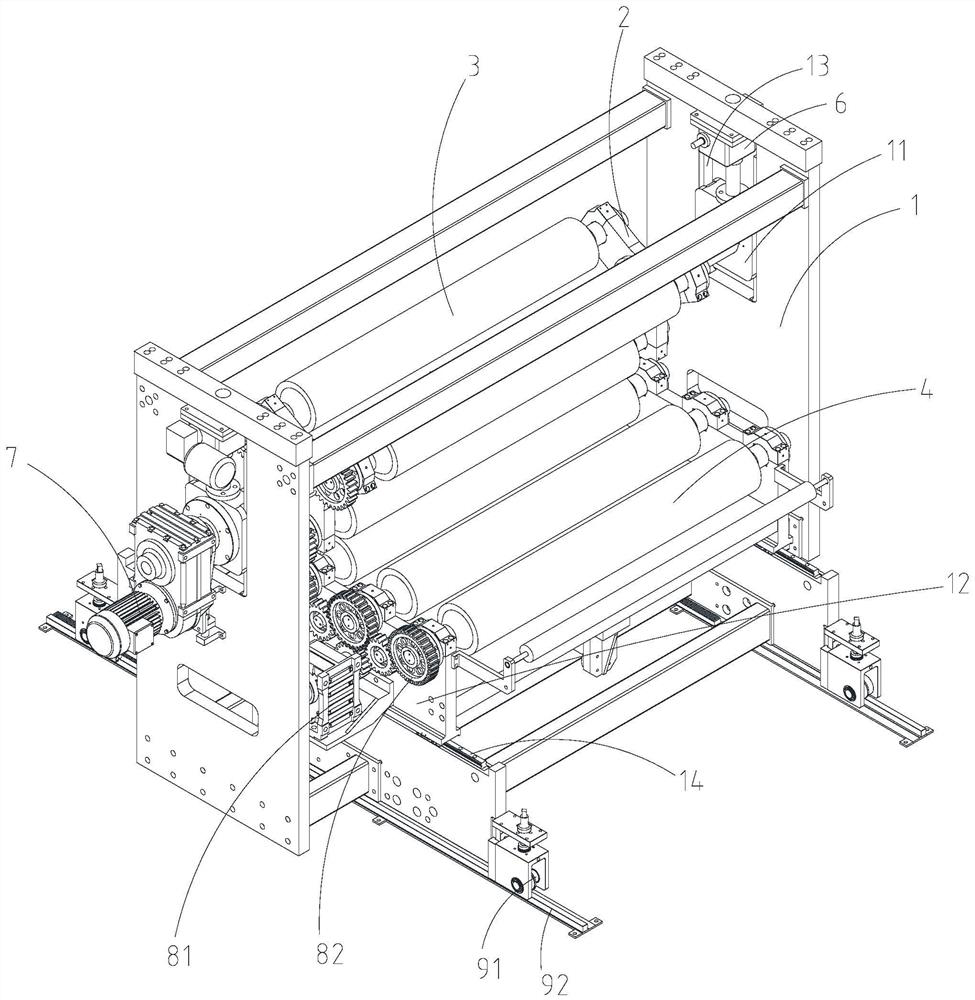

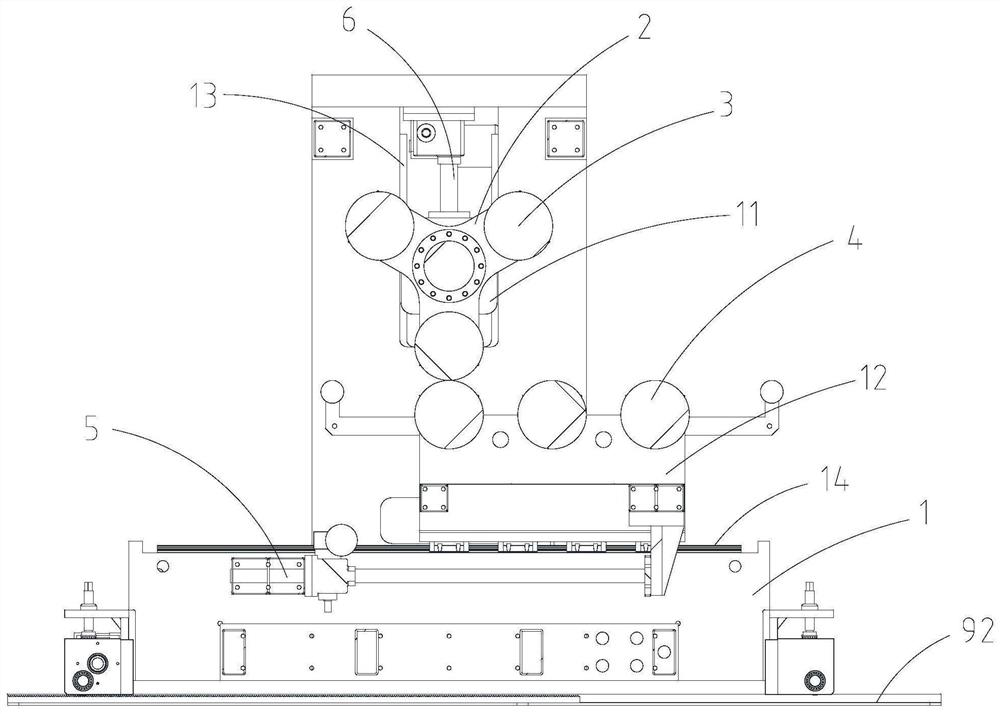

[0029] Such as figure 1 , 2 Shown, a kind of plastic plate multi-roller embossing machine, it comprises:

[0030] Frame 1, which is equipped with sliding block 11 and sliding frame 12 on its sliding;

[0031] The upper pattern roller assembly, which includes a turret 2 rotatably supported on the sliding block 11, at least two upper patterns arranged along the circumference of the turret 2 and rotatably supported on the turret 2 respectively The roller 3 and the upper pattern roller turning mechanism connected to the turret 2 to drive the turret 2 to rotate to a corresponding angle;

[0032] The lower patterned roller assembly, which includes at least two kinds of lower patterned rollers 4 arranged horizontally and rotatably supported on the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com