A big data-based online visual inspection system for injection molding and its equipment

A technology of visual inspection and big data, which is applied in the field of online visual inspection system and equipment for injection molding based on big data, which can solve the problems of not being able to protect the quality of mold products, not being able to take pictures of the whole mold, and damage to the mold cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

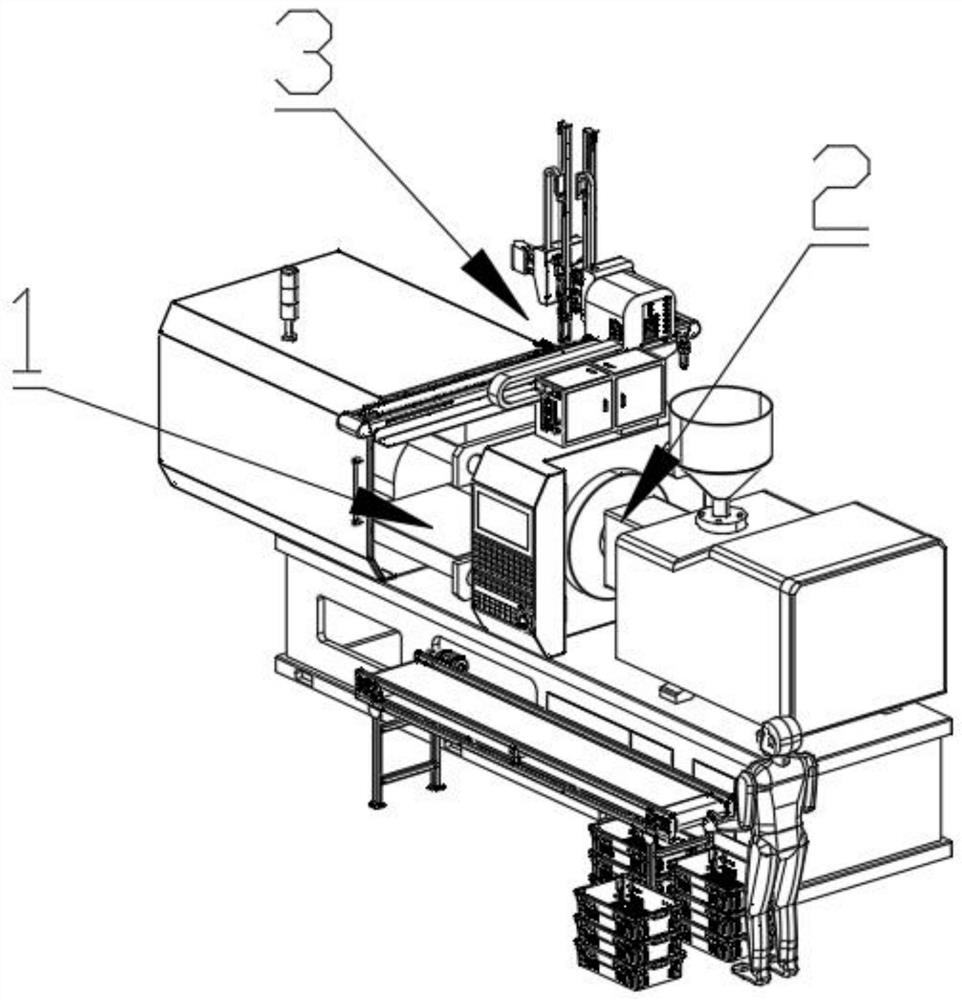

[0030]Embodiment 1: An online visual inspection system for injection molding based on big data and its equipment, including an extrusion device 2, a monitoring device 3, a networking device and a controller, the extrusion device 2 is configured to squeeze the extrusion material pressure; the monitoring device 3 monitors the extrusion process of the extrusion device 2 and transmits the monitored process to the controller; the networking device is configured to monitor the monitoring device 3 Carry out the transmission of data link with the processing of described extruding device 2; Described extruding device 2 comprises body, extruding rod, model chamber, storage box and first driving mechanism, and described extruding rod is arranged on the model One side of the cavity, and is arranged on the body, one end of the extruding rod is drivingly connected with the first driving mechanism, and the other end of the extruding rod protrudes toward the mold cavity, and the mold cavity T...

Embodiment 2

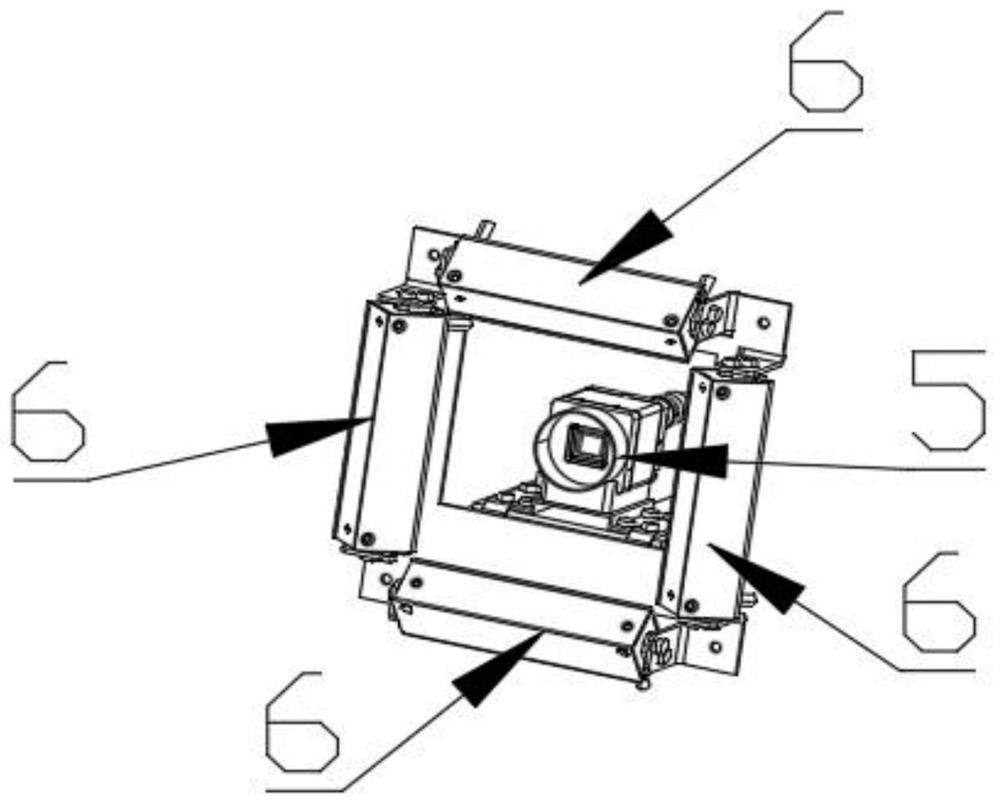

[0031] Embodiment 2: This embodiment should be understood as including at least all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, an online visual inspection system for injection molding based on big data and its equipment are provided. Including an extrusion device 2, a monitoring device 3, a networking device and a controller, the extrusion device 2 is configured to extrude the extrusion material; the monitoring device 3 controls the extrusion process of the extrusion device 2 monitor and transmit the monitoring process to the controller; the networking device is configured to perform data link transmission on the monitoring of the monitoring device 3 and the processing of the extrusion device 2; specifically, The cooperative use between the extrusion device 2 and the monitoring device 3 ensures that the extrusion device 2 can be detected during the extrusion process, and the extrusion force of the ...

Embodiment 3

[0036] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvements are made on the basis thereof. Specifically, a system for detection is provided, the system includes an excitation source, configured to provide a plurality of natural excitation intensities; the magnetic modulator configured to receive and modulate the plurality of intrinsic excitation intensities to form an output excitation intensities comprising a plurality of modulated excitation intensities, each of the modulated excitation intensities having main magnetic lines, wherein a first set of main magnetic lines on edges of the output excitation are parallel to each other along a magnetic axis; the magnetic modulator includes a magnetic intensity shaping assembly configured to The incident excitation strength formed based on the plurality of natural excitation strengths is shaped so that the main magnetic lines of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com