Equipment and method for detecting and repairing steel automobile wheel after forming

A technology for automobile hubs and equipment, applied in other manufacturing equipment/tools, metal processing equipment, manufacturing tools, etc., can solve problems such as waste of manpower, inspection omissions, hand scratches, etc., to increase the repair rate, prevent missed processing, increase workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

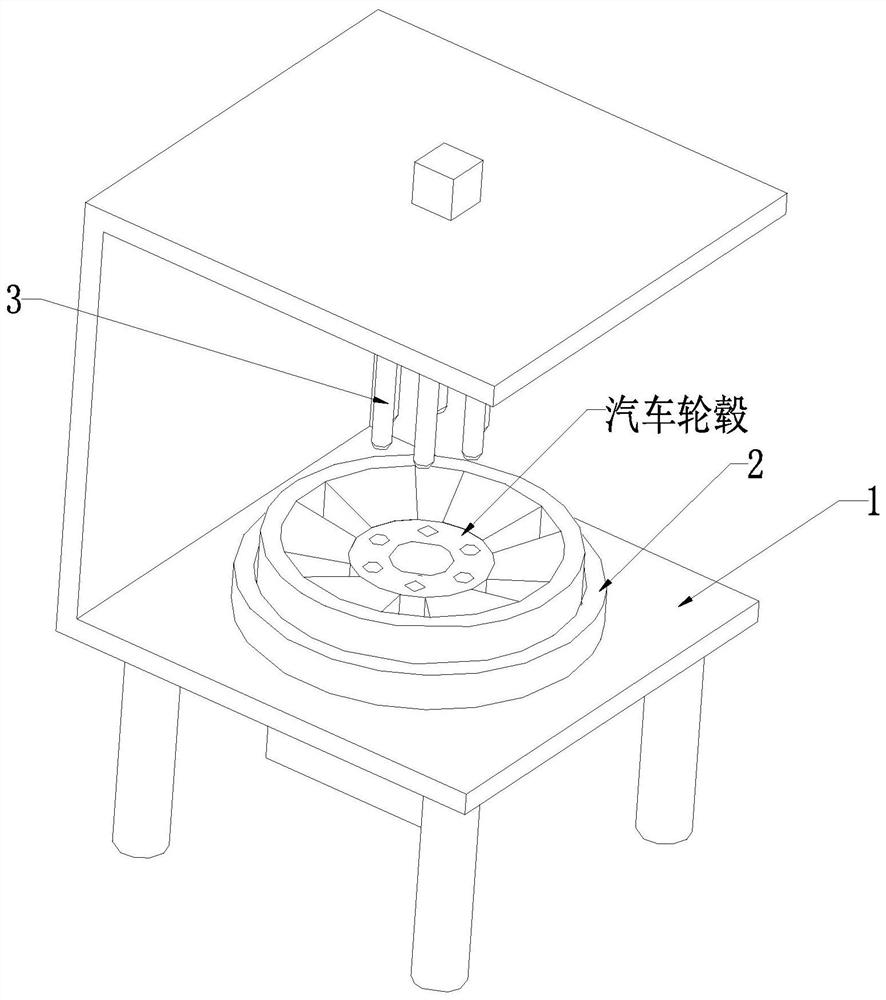

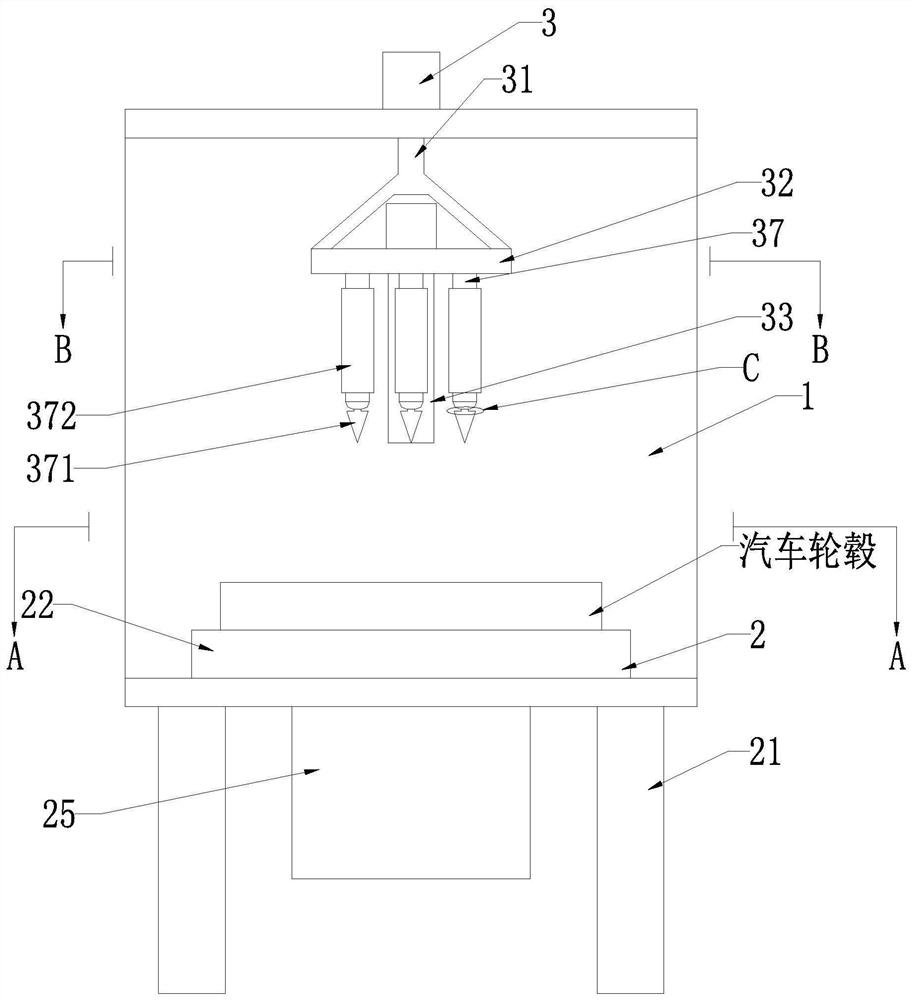

[0030] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0031] A detection and repair equipment for a steel automobile wheel after forming, including a mounting frame 1, a fastening set 2 and a repairing set 3, the mounting frame 1 is provided with a fastening set 2 and a repairing set 3 sequentially from bottom to top, wherein:

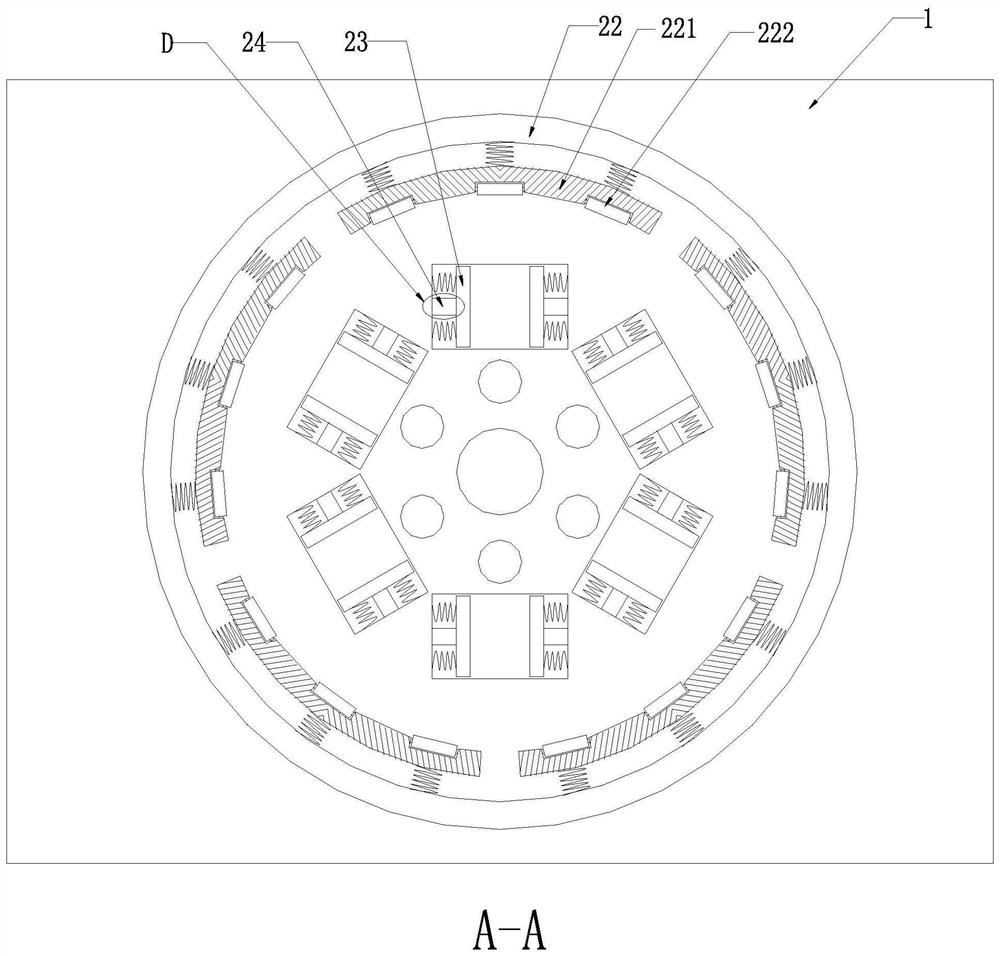

[0032] The fastening kit 2 includes a support column 21, an outer ring splint 22, a positioning splint 23, an adjustment block 24, a collection box 25 and a scraper block 26, and the support column 21 is uniformly installed on the lower end surface of the mounting frame 1 by welding, The outer ring splint 22 is fixedly installed on the mounting frame 1, and the positioning splint 23 is uniformly installed on the mounting frame 1 through a spring connection, and the outside of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com