A kind of sorting machine cleaning management method and system

A management system and machine cleaning technology, which is applied in the sorting machine cleaning management method and system field, can solve the problems that the automatic selection of printing templates cannot be realized, the automatic cleaning of sorting equipment cannot be realized, and the impact on equipment production capacity and product quality can be solved. Achieve the effect of simple and convenient hardware installation, reduce the discrepancies between accounts and materials, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

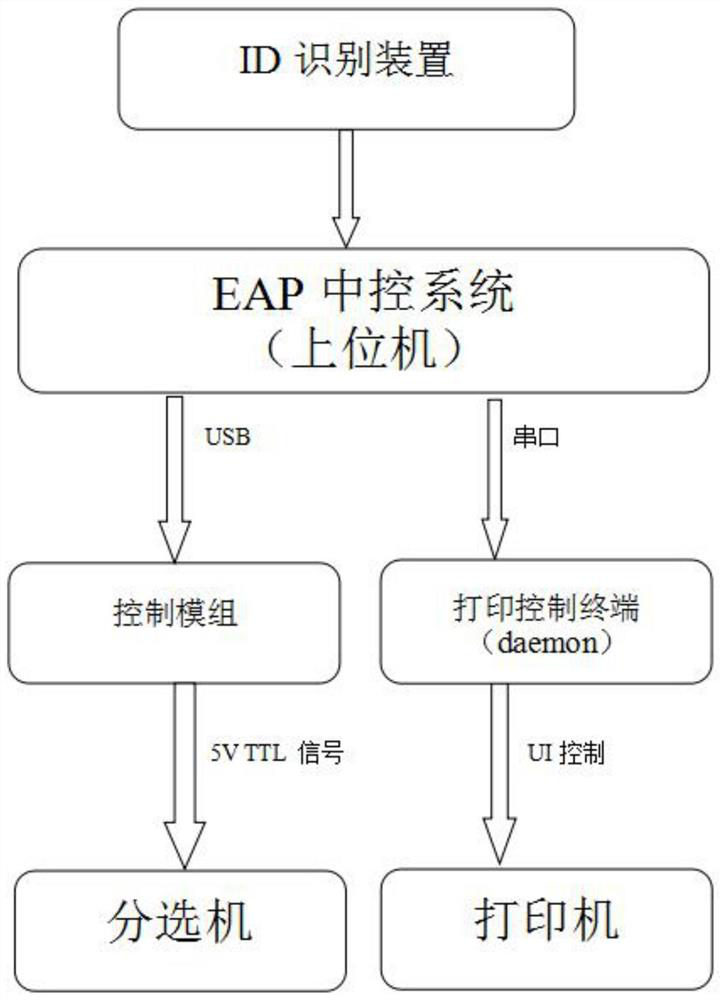

[0026] In order to make the technical means, creative features, goals and effects realized by the present invention easy to understand, the following embodiments describe the sorting machine cleaning management method and system of the present invention in detail with reference to the accompanying drawings.

[0027]

[0028] The present embodiment provides a sorting machine cleaning management method, which is characterized by comprising the following steps:

[0029] Step S1, obtaining the product type of the product to be sorted.

[0030] In step S2, it is judged whether the current product type is consistent with the last product type, and when the judgment result is "No", step S3 and step 5 are simultaneously entered.

[0031] In step S3, an automatic material clearing instruction is generated and transmitted to the control module through the upper computer.

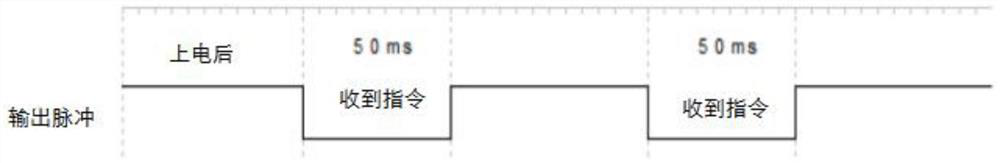

[0032] In step S4, the control module outputs a pulse signal to the sorting machine to run the material cleaning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com