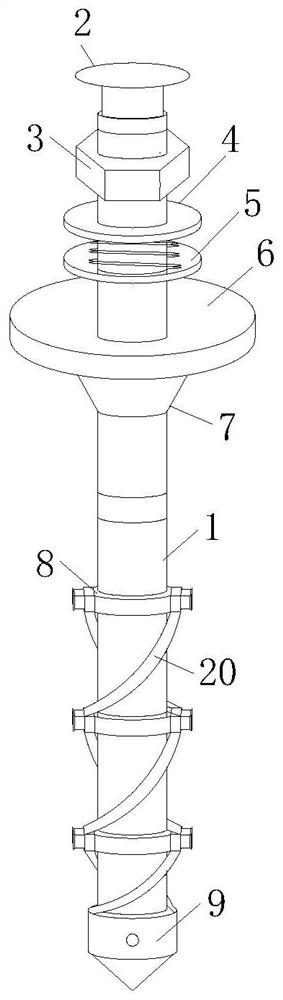

Flexible anchor rod

A bolt and flexible technology, which is applied in the installation of bolts, sheet pile walls, excavation, etc., can solve the problems of easy loosening, insufficient friction, and unstable anchor bolts, etc., and achieve good and stable fixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

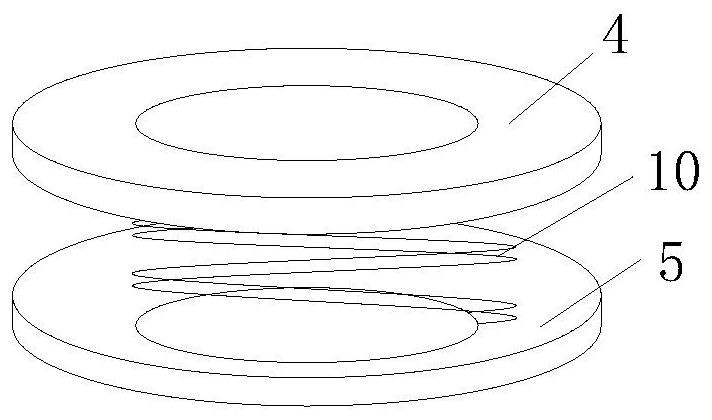

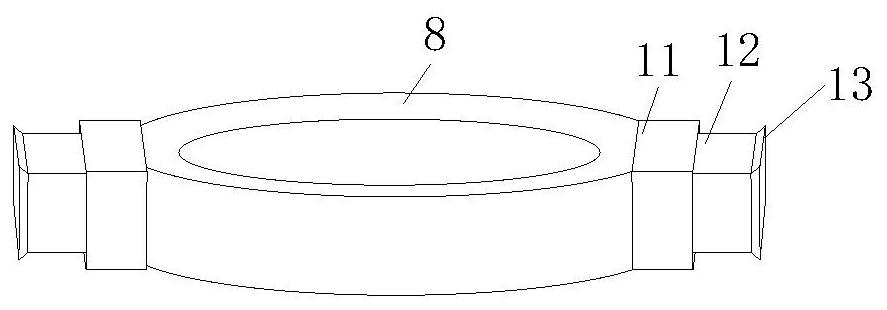

[0027] As an embodiment of the present invention, the anchor body 1 is provided with a hollow cavity; the connection disc 8 is provided with a connection hole 16; the connection hole 16 is used to communicate with the cavity and the casing 11 inside; a group of sliding plates 15 are slidably installed in the cavity; two sliding plates 15 are provided, and the two sliding plates 15 are fixedly connected by fixed rods, wherein the sliding plate 15 above is provided with a The magnet is in contact with a push rod 18; the end of the push rod 18 is provided with a No. 2 magnet 17 magnetically attracted to the No. 1 magnet, and the push rod 18 can move downward instantly under the push of an external force, thereby pushing two sliding plates 15 moves downward synchronously, the sliding plate 15 compresses the gas below, and the gas is sprayed out through the connecting hole 16 after being pressurized, so that the telescopic block 12 in the sleeve pipe 11 flies out instantly. When wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com