Bag type filtering equipment and using method thereof

A bag filtration and belt filtration technology, applied in fixed filter element filters, filtration separation, separation methods, etc., can solve the problems of high cost and limited filtration capacity, and achieve low cost, simple operation and large filtration capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

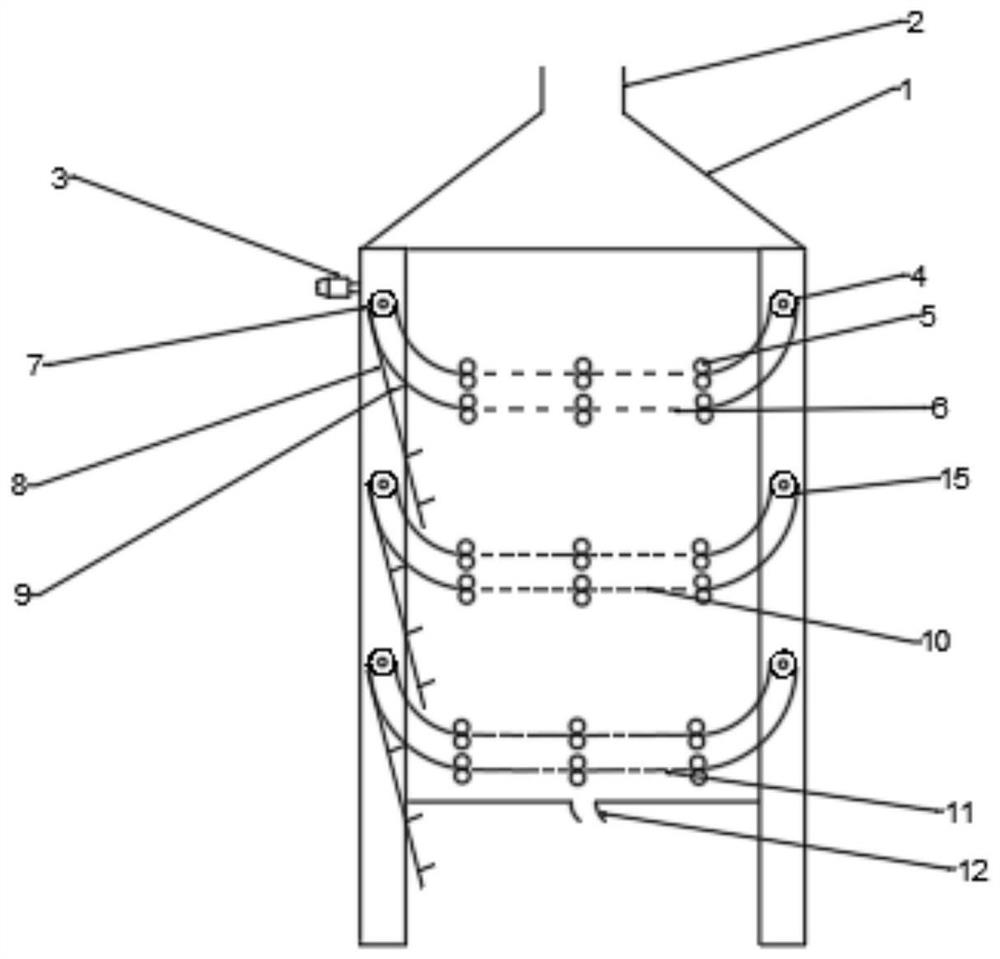

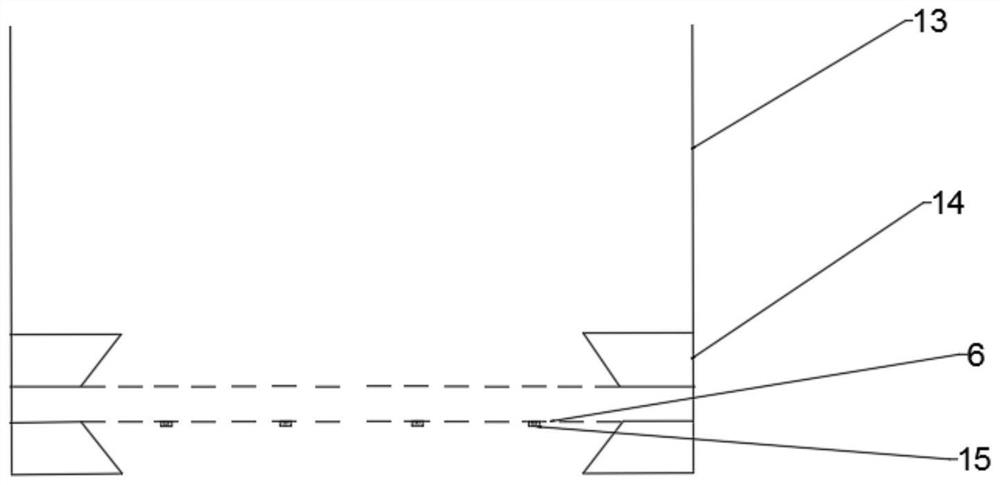

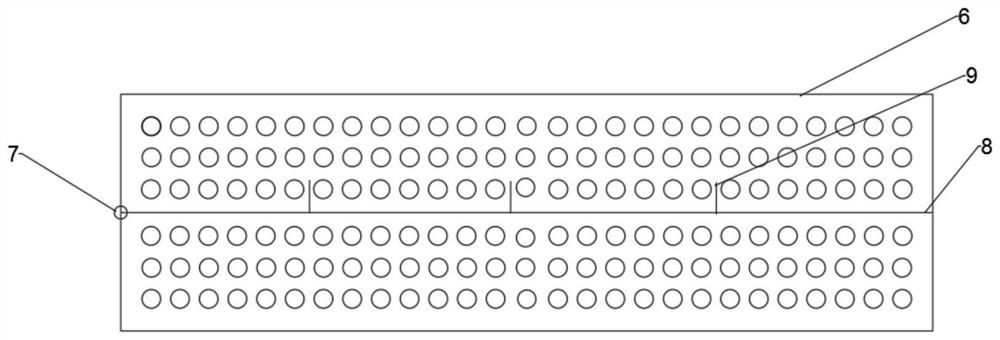

[0021] figure 1 and figure 2 Respectively show the parts of the bag filter equipment of the present invention, such as figure 1 and figure 2 Said, the parts of the bag filter equipment include support 1 and the water inlet 2 at the upper end of the support, motor 3 and scraper 8, fixed shaft 7 on the right side of the scraper, multiple springs 9 on the scraper, and multiple springs 9 fixed on the support. Gear 4, fixed shaft 5 distributed on the upper and lower sides of the filter screen, 200-mesh modular filter screen 6, 400-mesh modular filter screen 10 and 600-mesh modular filter screen 11, which are embedded on the filter screen with gears number of chains 15, the modular water retaining plate 13 distributed on both sides of the filter screen and the filter screen guide groove 14 distributed on the upper and lower sides of the filter screen, the drain outlet 12 at the lower end of the support; the water inlet 2 at the upper end of the support 1 is opened, and the sewag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com